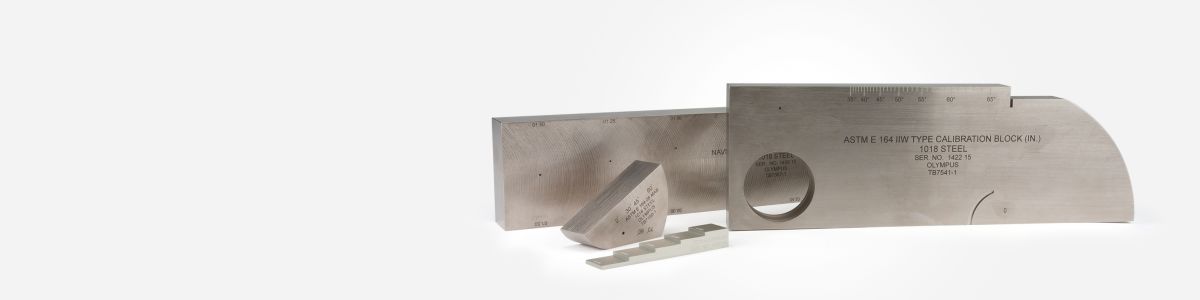

校正用試験片

校正用/標準試験片は全てのアプリケーションで必要とされます。標準試験片では、一般的な素材の斜角校正と厚さ校正が行えます。

- 1018スチール、304ステンレス、または7075-T6アルミニウムで作成された試験片は一般的に在庫として準備されています。(その他の素材については、お近くのオリンパスまでお問い合わせください。)

- リストに無い試験片やカスタム試験片については、お近くのオリンパスまでお問い合わせください。

校正用試験片

校正用試験片

全ての試験片は、NIST(National Institute of Standards and Technology)に基づき測定されているものです。一般的な校正用試験片は以下のリストの通りです。

タイプ | 製品型番 | 内容 | ケース |

ASTM E164 Calibration IIW-Type Block | TB7541-X | Meets AASHTO and AWS Type 1 block requirements. Calibrates distance and sensitivity settings. Measure refracted angle and sound exit point of angle beam transducers. U.S. customary units (inches). | F129 |

| TB1136-X | U.S. customary units (inches) block with Lucite® plug | F129 | |

TB1054-X | Metric Units | F129 | |

TB1137-X | Metric Units block with Lucite® plug | F129 | |

US Air Force

| TB5939-X | IIW-type block per U.S. Air Force NDI Manual T.O. 33B -1-1. Includes 2" and 4" radius cutouts for distance calibration. No. 3, No. 5 and No. 8 side drilled holes, and distance calibration marks to the 2" hole. | F129 |

RC AWS Block | TB7543-X | Determining resolution capabilities of angle beam transducers per AWS and AASHTO requirements. | F157 |

SC AWS Block | TB7545-X | Sensitivity and refracted angle calibration per AWS and AASHTO requirements. | F158 |

DC AWS Block | TB7547-X | Distance and beam index calibration for angle beam transducers per AWS and AASHTO requirements. | F159 |

DSC AWS Block | TB7549-X | Distance, sensitivity, refracted angle and beam index calibration for angle beam transducers per AWS and AASHTO requirements. | F160 |

DS AWS Block | TB7551-X | Calibration block for horizontal linearity and dB accuracy procedures per AWS and AASHTO requirements. | F161 |

30FBH Resolution Reference Block | TB7160-X | Evaluate near surface resolution and flaw size/depth sensitivity of UT equipment. No. 3, No. 5 and No. 8 ASTM flat bottom holes at ten metal travel distances from 0.050" to 1.250". | Included |

NAVSHIPS Block | TB7567-X | Contains six No. 3 side drilled holes. Used for distance-amplitude calibration per NAVSHIPS 0900-006 -3010. | F162 |

ASTM E164 MAB Block | TB7150-X | Miniature Angle Beam (ROMPAS) Block. Distance, beam index, refracted angle and sensitivity calibration. One inch thick. | F197 |

ISO 7963 Steel | TB1065-X | Miniature Angle Beam Block Distance, beam index, refracted angle and sensitivity calibration. 25 mm thick. | F197 |

上記製品型番の"X"部分は、以下の試験片素材の内容に沿った番号と差し替えてください: 1 = 1018スチール、2 = 4340スチール、4 = 7075-T6アルミニウム、5 = 304ステンレススチール、8 = 6-4チタン

標準試験片

標準試験片

オリンパスではASTM標準によって推奨されている標準試験片を取り扱っており、ASTM E127とASTM E428の測定方法に沿って製造されています。全ての標準試験片と一緒に「超音波反射カーブ」を提供しています。また、下記リストには無い試験片やカスタム試験片については、お近くのオリンパスまでお問い合わせください。

セットタイプ* | 製品型番 | セット内容 | |||||||

Distance-

| TB6100-X | Set of 10 ASTM E 127 (7075 Alum) or ASTM E 428 (all other materials) basic set consisting of 3/64 at 3", 5/64 at 1/8", 1/4", 1/2", 3/4", 1-1/2", 3", and 6", and 8/64 at 3" and 6". This set is used for determining Dead Zone, Sensitivity, Distance and Area Amplitude Linearity Measurement. | |||||||

Area-

| TB6200-X | Set of 8 ASTM E 127 (7075 Alum) or ASTM E 428 (all other materials) Area Amplitude Set consisting of 1/64, 2/64, 3/64, 4/64, 5/64, 6/64, 7/64, and 8/64 Flat Bottom Holes at 3". This set is used to determine the relationship between flaw size and echo amplitude by comparing signal response. | |||||||

Distance-

| TB6303-X | Set of 19 ASTM E 127 (7075 Alum) or ASTM E 428 (all other materials) Distance Amplitude Set. All Flat Bottom Holes are the same and metal travel distances are 1/16", 1/8", 1/4", 3/8", 1/2", 5/8", 3/4", 7/8", 1", 1-1/4", 1-3/4", 2-1/4", 2-3/4" 3-1/4", 3-3/4", 4-1/4", 4-3/4", 5-1/4", and 5-3/4". This set is used to determine the relationship between metal distance and signal amplitude by comparing signal responses obtained. | |||||||

Distance-

| TB6305-X | 1/16" | 1/2" | 1" | 2-1/4" | 3-1/4" | 4-1/4" | 5-1/4" | |

Set-No. 5FBH | 1/8" | 5/8" | 1-1/4" | 2-3/4" | 3-3/4" | 4-3/4" | 5-3/4" | ||

Distance-

| TB6308-X | 1/4" | 3/4" | 1-3/4" | |||||

Set-No. 8FBH | 3/8" | 7/8" | |||||||

Sensitivity-

| TB6025-X | Set of 9 ASTM E 127 (7075 Alum) or ASTM E 428 (all other materials) consisting of 1/64 at 3"9, 2/64 at 3", and 5/64 at 1/8", 1/4" 3/8", 1/2", 3/4" 1" and 1-1/2", and 1 ASTM E 317 Horizontal and Vertical Linearity Block used to evaluate the sensitivity, entry surface resolution, and horizontal and vertical linearity characteristics of UT equipment. | |||||||

上記製品型番の"X"部分は、以下の試験片素材の内容に沿った番号と差し替えてください: 1 = 1018スチール、2 = 4340スチール、4 = 7075-T6アルミニウム、5 = 304ステンレススチール、8 = 6-4チタン

厚さ測定校正用試験片

厚さ測定校正用試験片

- ASTM E797コード指令よりも厳しい許容範囲で作成されています。

製品型番 | 素材 | ステップ |

2211E | 304 Stainless Steel | 0.100", 0.200", 0.300", 0.400", 0.500" |

2211M | 304 Stainless Steel | 2.5 mm, 5.0 mm, 7.5 mm, 10.0 mm, 12.5 mm |

2212E | 1018 Carbon Steel | 0.250", 0.500", 0.750", 1.00" |

2212M | 1018 Carbon Steel | 6.25 mm, 12.5 mm, 18.75 mm, 25 mm |

2213E | 7075-T6 Aluminum | 0.100", 0.200", 0.300", 0.400", 0.500" |

2213M | 7075-T6 Aluminum | 2.5 mm, 5.0 mm, 7.5 mm, 10.0 mm, 12.5 mm |

2214E | 1018 Carbon Steel | 0.100", 0.200", 0.300", 0.400", 0.500" |

2214M | 1018 Carbon Steel | 2.5 mm, 5.0 mm, 7.5 mm, 10.0 mm, 12.5 mm |