X-STREAM(現在、日本では対応しておりません)

概要

|  |

Glass Cullet: Removal of Leaded and Heat Resistant Glass from Glass Cullet Streams

For some time, glass ceramics have been causing problems throughout the glass recycling industry. The melting behavior of glass ceramics is different from that of 'normal' glass; therefore, they will not dissolve in the melting tank at the glassworks, or dissolve only with great difficulty. This poses an array of problems; from serious damage and fire-hazard during the production process to defects or inclusions in the final product. The expanded use of glass ceramics and its tendency to turn up in recycling glass is on the rise; and it is problematic for glass collectors and processors to recognize glass ceramics visually when conducting inspection for incoming materials. In conjunction with the rising glass ceramics problem, glass recyclers are also facing the challenge of keeping the lead content of their glass cullet below a certain level, due to the increased stringency of legeslated regulations.

For some time, glass ceramics have been causing problems throughout the glass recycling industry. The melting behavior of glass ceramics is different from that of 'normal' glass; therefore, they will not dissolve in the melting tank at the glassworks, or dissolve only with great difficulty. This poses an array of problems; from serious damage and fire-hazard during the production process to defects or inclusions in the final product. The expanded use of glass ceramics and its tendency to turn up in recycling glass is on the rise; and it is problematic for glass collectors and processors to recognize glass ceramics visually when conducting inspection for incoming materials. In conjunction with the rising glass ceramics problem, glass recyclers are also facing the challenge of keeping the lead content of their glass cullet below a certain level, due to the increased stringency of legeslated regulations.

BT-Wolfgang Binder utilizes X-STREAM sensor technology in their REDWAVE XRF G glass sorting systems which offers glass cullet processors the ability to sort glass by elemental composition. The XRF sensor searches for certain elements such as Titanium, Zinc, Zirconium (which are typical markers for glass ceramics) and Lead. The system then efficiently extracts the contaminations by using air jet diversion. The REDWAVE XRF G systems by BT-Wolfgang Binder are capable of processing up to 28 tons/hour of glass cullet, extracting glass ceramics and leaded glass simultaneously.

BT-Wolfgang Binder utilizes X-STREAM sensor technology in their REDWAVE XRF G glass sorting systems which offers glass cullet processors the ability to sort glass by elemental composition. The XRF sensor searches for certain elements such as Titanium, Zinc, Zirconium (which are typical markers for glass ceramics) and Lead. The system then efficiently extracts the contaminations by using air jet diversion. The REDWAVE XRF G systems by BT-Wolfgang Binder are capable of processing up to 28 tons/hour of glass cullet, extracting glass ceramics and leaded glass simultaneously.

X-STREAM: Metal

|  |

Benefits:

- A high level of detection is guaranteed even in the presence of material which is dirty or otherwise contaminated

- Elemental analysis of the feed material

- Color independent recognition is possible (for example, for the sorting of aluminium, zinc, stainless steel)

- Sorting of alloys

Possible applications:

- Sorting of slag: separation of various metals from a mixture of slag and metals

- Sorting of aluminum

- Separation of various impurities of metallic origin (Cu, Zn, VA, brass, Pb, etc.)

- Separation of various impurities of different origin (e.g. wood, plastics) by means of camera technology

- Separation of aluminum alloys with a higher Zn or Cu content

- Sorting of stainless steels

- Separation of impurities such as Cu, Zn, brass, Pb, Sn in pure form and in the form of alloys. A pure fraction of steel / stainless steel is produced

- Separation of stainless steels from a mixture of steel and stainless steel

- Separation of stainless steels with Mo contents according to adjustable Mo concentration

- Separation of stainless steels with Ni contents according to adjustable Ni concentrations

- Sorting of non-ferrous metals and other metals

- Separation of Cu, Zn, brass, etc. in pure fractions

- Production of a pure Cu fraction

- Production of a pure brass fraction

- Separation of Cu, Zn, brass, etc. in pure fractions

- Sorting of precious metals

- Separation of materials containing Au

- Separation of materials containing Ag

- Special applications

- Sorting of Cu tubes

- Separation of Ag soldering joints

- In general: Sorting of various alloys on the basis of differences in the composition of the elements, e.g. presence of an element in alloy A, which is not existent in B and C, etc.

- Sorting of Cu tubes

仕様

スクラップおよびガラスカレットの分類用蛍光X線自動分析装置X-STREAMX-STREAMとX-STREAM: ガラスは、化学組成により自動で識別・分類する高速自動ソーティングシステムです。 金属、ガラス、鉱物のリサイクルを、スピード、正確性、収益性において新たなレベルに引き上げています。 |  |

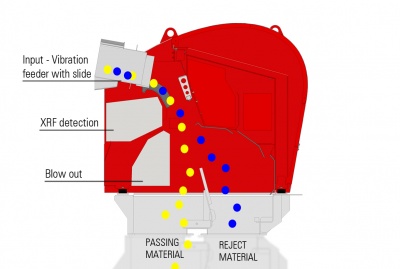

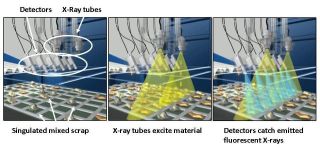

迅速で正確なソーティング技術X-STREAMは定評ある蛍光X線分析(XRF)に基づいた完全自動のインラインシステムであり、化学組成によってスクラップ材料を識別します。 |

通常、XRF自動ソーティングシステムは、ベルトコンベヤーに搭載されたスペクトロメーターモジュールで構成されています。そこに組み込まれた複数のX線管と検出器によって、スクラップ材料の1つ1つを検出・分析することができます。 わずか数ミリ秒以内でそれぞれの化学組成が算出され、ユーザー定義が可能な分類パラメーターによって、対象物を振り分けることができます。

主な仕様は以下のとおりです。

- 塩素(Cl)からウラニウム(U)までの元素の同定

- 高輝度X線源

- 堅牢で固体状態での検査が可能な高分解能検出器

- IRカメラ切り替え

- ミリ秒の信号処理

- 強固かつ柔軟性のあるソフトウェアプラットフォーム

X-STREAMのソフトウェア構成では、基準の変更や新たな市場需要に合わせ、迅速にオンサイトでのソフトウェア変更が可能です。

- バッチまたは連続のインラインモード

- 個別の構成部品または完全なターンキーシステムを提供

- 各種のプロセス構成に合わせたカスタマイズが容易

- パフォーマンスニーズに合うように各種のベルトコンベヤ、フィーダー、ダイバーターと連動

- 1つの設備で多用途に対応

- 複数の用途を1つの設備に統合

X-STREAMは自動の大容量テクノロジーを取り入れ、物理的特性ではなく高精度の化学分析に基づいて、スクラップ材料やリサイクル材料を分類します。 XRFを使用した元素組成別の分類を行うことで、リサイクル産業に新たな分類の機会と現在抱える課題への独自のソリューションをもたらします。スクラップ分類のレベルが高くなるほど、理想的な100%リサイクルの目標へと近づきます。 この独特のシステムは、過流ソーター、インダクションソーター、媒体分離機器と連動して、金属やガラスリサイクルの回収率を向上させ、資産価値を高めます。 処理済み材料の価値を最大化するのに役立ちます。 使いやすく、素早く分析が行え、かつ費用効果が高くなっています。

以下の特長があります。

- 高精度の分類 - 通常>95%

- 高い効率性で分類 - 通常>90%

- 1時間当たりトン単位の容量の処理が可能

- 需要に合わせ分類基準の変更が可能な柔軟性

- 最高価値の製品を1回のパスで

- 低い所有コストで業界内での信頼性が高いシステム

自動のXRFセンサーテクノロジーは多様なスクラップ材料に適用できるため、さまざまなリサイクル業界に貢献します。 X-STREAMテクノロジーがスクラップ処理業者に有益であるたくさんの例の一部としては、鉄片からの銅塊の抽出、組成または合金品種による非鉄金属の分類、ガラスの分類があります。 オリンパスのInnov-XはXRFテクノロジーを熟知しており、X-Streamセンサーの開発および製造のみに焦点を絞っています。 X-Streamセンサーは、現在ソーティングシステムメーカーであるBT-Wolfgang Binderで使用されおり、実績のあるソーティングシステムに導入されています。

X-STREAMソーティングシステムの詳細については、BT-Wolfgang Binder GmnbHをご参照ください。