Kalibrační bloky

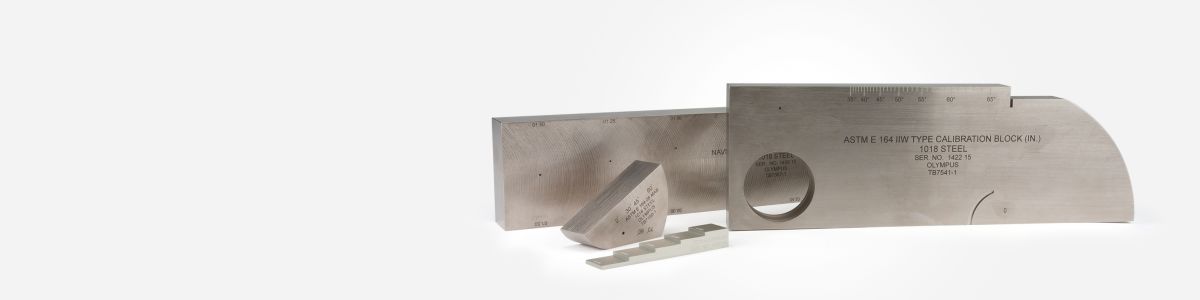

Calibration and/or Reference Blocks should be used in every application. Standard blocks are available for angle beam calibrations and thickness calibrations of common materials.

- Blocks manufactured from 1018 steel, 304 stainless steel, or 7075-T6 aluminum are commonly in stock (other materials require special quotes for price and delivery)

- Contact us for more information regarding materials not listed, blocks not listed, or custom blocks

Calibration Blocks

Calibration Blocks

All blocks are checked dimensionally using measuring equipment traceable to the National Institute of Standards and Technology, NIST. The most commonly required calibration blocks are listed below.

Type | Part Number | Description | Case |

ASTM E164 Calibration IIW-Type Block | TB7541-X | Meets AASHTO and AWS Type 1 block requirements. Calibrates distance and sensitivity settings. Measure refracted angle and sound exit point of angle beam transducers. U.S. customary units (inches). | F129 |

| TB1136-X | U.S. customary units (inches) block with Lucite® plug | F129 | |

TB1054-X | Metric Units | F129 | |

TB1137-X | Metric Units block with Lucite® plug | F129 | |

US Air Force

| TB5939-X | IIW-type block per U.S. Air Force NDI Manual T.O. 33B -1-1. Includes 2" and 4" radius cutouts for distance calibration. No. 3, No. 5 and No. 8 side drilled holes, and distance calibration marks to the 2" hole. | F129 |

RC AWS Block | TB7543-X | Determining resolution capabilities of angle beam transducers per AWS and AASHTO requirements. | F157 |

SC AWS Block | TB7545-X | Sensitivity and refracted angle calibration per AWS and AASHTO requirements. | F158 |

DC AWS Block | TB7547-X | Distance and beam index calibration for angle beam transducers per AWS and AASHTO requirements. | F159 |

DSC AWS Block | TB7549-X | Distance, sensitivity, refracted angle and beam index calibration for angle beam transducers per AWS and AASHTO requirements. | F160 |

DS AWS Block | TB7551-X | Calibration block for horizontal linearity and dB accuracy procedures per AWS and AASHTO requirements. | F161 |

30FBH Resolution Reference Block | TB7160-X | Evaluate near surface resolution and flaw size/depth sensitivity of UT equipment. No. 3, No. 5 and No. 8 ASTM flat bottom holes at ten metal travel distances from 0.050" to 1.250". | Included |

NAVSHIPS Block | TB7567-X | Contains six No. 3 side drilled holes. Used for distance-amplitude calibration per NAVSHIPS 0900-006 -3010. | F162 |

ASTM E164 MAB Block | TB7150-X | Miniature Angle Beam (ROMPAS) Block. Distance, beam index, refracted angle and sensitivity calibration. One inch thick. | F197 |

ISO 7963 Steel | TB1065-X | Miniature Angle Beam Block Distance, beam index, refracted angle and sensitivity calibration. 25 mm thick. | F197 |

Replace the "X" in the part number with the appropriate number listed below to signify block material: 1 = 1018 Steel, 2 = 4340 Steel, 4 = 7075-T6 Aluminum, 5 = 304 Stainless Steel, 8 = 6-4 Titanium

Reference Blocks

Reference Blocks

We offer commonly used sets of reference blocks recommended by ASTM standards. These sets are all manufactured to ASTM E127 and ASTM E428 physical dimensions requirements. All reference blocks are provided with an ultrasonic response curve. We can provide, by special order, materials not listed and individual reference blocks. Contact us for more information regarding materials not listed, custom calibration blocks, or quotations on blocks not listed in this section.

Type of Set* | Part Number | Description of Set | |||||||

Distance-

| TB6100-X | Set of 10 ASTM E 127 (7075 Alum) or ASTM E 428 (all other materials) basic set consisting of 3/64 at 3", 5/64 at 1/8", 1/4", 1/2", 3/4", 1-1/2", 3", and 6", and 8/64 at 3" and 6". This set is used for determining Dead Zone, Sensitivity, Distance and Area Amplitude Linearity Measurement. | |||||||

Area-

| TB6200-X | Set of 8 ASTM E 127 (7075 Alum) or ASTM E 428 (all other materials) Area Amplitude Set consisting of 1/64, 2/64, 3/64, 4/64, 5/64, 6/64, 7/64, and 8/64 Flat Bottom Holes at 3". This set is used to determine the relationship between flaw size and echo amplitude by comparing signal response. | |||||||

Distance-

| TB6303-X | Set of 19 ASTM E 127 (7075 Alum) or ASTM E 428 (all other materials) Distance Amplitude Set. All Flat Bottom Holes are the same and metal travel distances are 1/16", 1/8", 1/4", 3/8", 1/2", 5/8", 3/4", 7/8", 1", 1-1/4", 1-3/4", 2-1/4", 2-3/4" 3-1/4", 3-3/4", 4-1/4", 4-3/4", 5-1/4", and 5-3/4". This set is used to determine the relationship between metal distance and signal amplitude by comparing signal responses obtained. | |||||||

Distance-

| TB6305-X | 1/16" | 1/2" | 1" | 2-1/4" | 3-1/4" | 4-1/4" | 5-1/4" | |

Set-No. 5FBH | 1/8" | 5/8" | 1-1/4" | 2-3/4" | 3-3/4" | 4-3/4" | 5-3/4" | ||

Distance-

| TB6308-X | 1/4" | 3/4" | 1-3/4" | |||||

Set-No. 8FBH | 3/8" | 7/8" | |||||||

Sensitivity-

| TB6025-X | Set of 9 ASTM E 127 (7075 Alum) or ASTM E 428 (all other materials) consisting of 1/64 at 3"9, 2/64 at 3", and 5/64 at 1/8", 1/4" 3/8", 1/2", 3/4" 1" and 1-1/2", and 1 ASTM E 317 Horizontal and Vertical Linearity Block used to evaluate the sensitivity, entry surface resolution, and horizontal and vertical linearity characteristics of UT equipment. | |||||||

Replace the "X" in the part number with the appropriate number listed below to signify block material: 1 = 1018 Steel, 2 = 4340 Steel, 4 = 7075-T6 Aluminum, 5 = 304 Stainless Steel, 8 = 6-4 Titanium

Thickness Calibration Blocks

Thickness Calibration Blocks

- Blocks are held to tighter tolerances than called out in ASTM E797 Code.

Part Numbers | Material | Steps |

2211E | 304 Stainless Steel | 0.100", 0.200", 0.300", 0.400", 0.500" |

2211M | 304 Stainless Steel | 2.5 mm, 5.0 mm, 7.5 mm, 10.0 mm, 12.5 mm |

2212E | 1018 Carbon Steel | 0.250", 0.500", 0.750", 1.00" |

2212M | 1018 Carbon Steel | 6.25 mm, 12.5 mm, 18.75 mm, 25 mm |

2213E | 7075-T6 Aluminum | 0.100", 0.200", 0.300", 0.400", 0.500" |

2213M | 7075-T6 Aluminum | 2.5 mm, 5.0 mm, 7.5 mm, 10.0 mm, 12.5 mm |

2214E | 1018 Carbon Steel | 0.100", 0.200", 0.300", 0.400", 0.500" |

2214M | 1018 Carbon Steel | 2.5 mm, 5.0 mm, 7.5 mm, 10.0 mm, 12.5 mm |