Cylinder liner

Application

The cylinder liners of combustion chambers in engine blocks directly contact the pistons moving inside the chambers. To enable smooth piston movement, the inner surface of the cylinder liners must be adequately lubricated. Grooves on the cylinder liners help provide the required layer of lubricant. These grooves are called cross hatches. In addition, the inner surface of a cylinder must have a specific roughness condition to ensure the proper sliding performance. To evaluate cylinder liners, three characteristics must be examined:

- Cross-hatch configuration

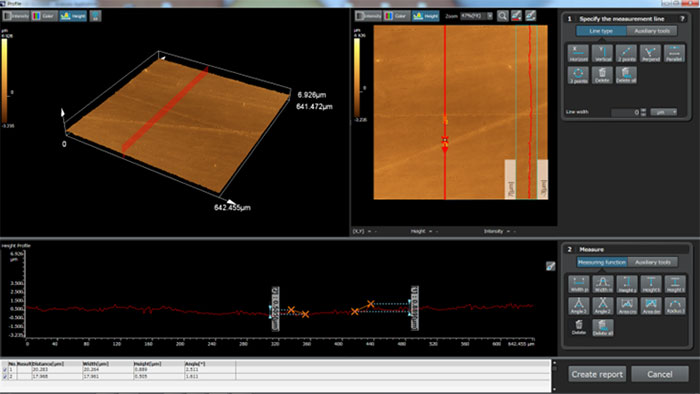

- Cylinder liner surface roughness

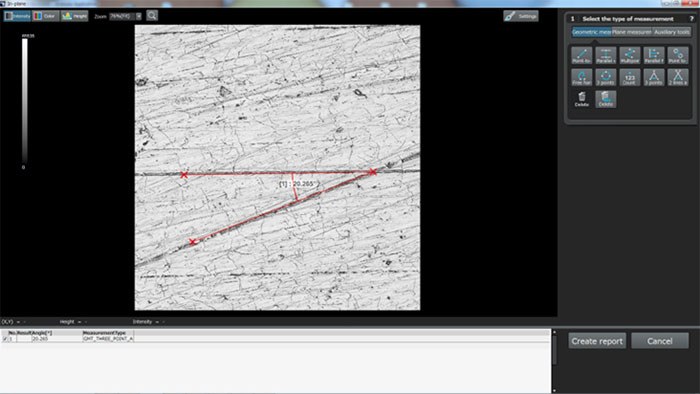

- Cross-hatch intersecting angle

Solution

The LEXT OLS5000 microscope uses lasers to perform 3D measurement of the delicate surface features of cylinder liners, which is necessary for quality management.

LEXT OLS5000 product features

- Improved resolution (plane resolution of 0.12 μm) achieves high-precision measurement.

- Roughness measurement capability enables the acquisition of accurate measurement data.

- Smart scan functionality enables fully automatic acquisition of 3D data, which helps minimize differences in the data acquired by different microscope operators.

- Image stitching function enables high-precision measurement within a broad field of view.

Images

|

|

Cylinder liner image Cylinder liner image (reproduction) provided by a laser microscope (objective lens: 20X; zoom: 1x) | |

Cross-hatch configuration image (reproduction) during measurement

Interior surface roughness image (reproduction) during measurement

Cross-hatch intersecting angle image (reproduction) during measurement