- Überblick

- Empfohlene Modelle

- Bedienbarkeit

- Höhenmessung

- Messunterstützungssystem

- Spezifikationen

- Informationsmaterialien

Überblick

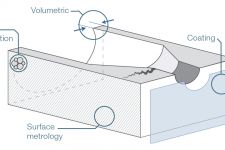

Ein Messmikroskop für

|

|

|---|

Hervorragende optische EigenschaftenDie Serie STM7 verwendet dasselbe unendlich korrigierte optische System UIS2, das auch in hochmodernen Lichtmikroskopen zu finden ist. |

|---|

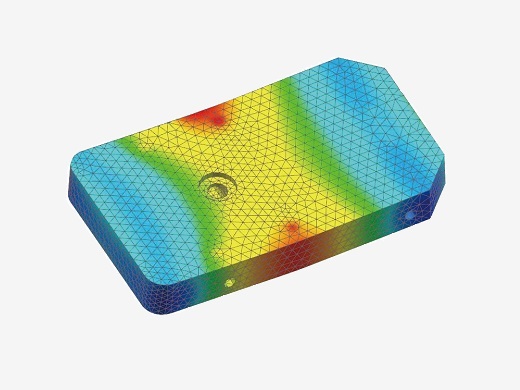

STM7-LF FEM-Analyse | Zuverlässige Messungen mit einer Stein-Tischeinlage der MontageplatteUm die Messgenauigkeit weiter zu verbessern, verwendet die Serie STM7 ein äußerst haltbares, vibrationsbeständiges Stativ mit einer Granitarbeitsplatte. Diese Stabilität ermöglicht Messungen im Submikrometerbereich mit minimalen Fehlern. |

|---|

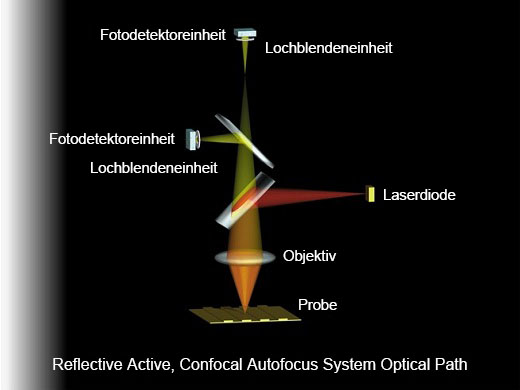

Benutzerfreundliche, hochpräzise 3-Achsen-MessungDa die moderne Fertigungstechnologie zunehmend miniaturisiert und präziser wird, werden auch hochgenaue Messungen wichtiger – nicht nur in den XY-Achsen, sondern auch auf der Z-Achse. Olympus reagierte darauf mit der Schaffung des ersten aktiven, konfokalen Auflicht-Autofokussystems. |  |

|---|

| Zuverlässige Qualität durch striktes RückverfolgbarkeitssystemDie Genauigkeit der Messmikroskope von Olympus wird durch ein strenges System der Rückverfolgbarkeit kontrolliert; Olympus bietet sogar eine rückverfolgbare Kalibrierung zum Zeitpunkt der Installation an. |

|---|

Empfohlene Modelle

Zuverlässige modulare SystemeAus fünf Konfigurationen können Sie flexibel die Funktionen auswählen, die Sie benötigen. |

| Manuell bediente Modelle | Motorgesteuerte Modelle | |||||||

STM7-SF | STM7-MF | STM7-LF | STM7-MFA | STM7-LFA | ||||

|  |  |  |  | ||||

STM7-CS100 | STM7-CS200 | STM7-CS300 | STM7-CS200 | STM7-CS300 | ||||

|  |  |  |  | ||||

Siehe Spezifikationstabelle

| STM7-SF | STM7-MF | STM7-LF | STM7-MFA | STM7-LFA | |

| Z-Achsen-Fokus | Manuell | Manuell | Motorgesteuert | ||

| Standard | HF oder HF/DF | HF oder HF/DF | HF oder HF/DF | ||

| Option | DIC POL | DIC POL | DIC POL | ||

| Messobjektive Hellfeld |  |  |  | ||

| Fokus-Navigator STM7-FN |  |  |  | ||

| Autofokus-Einheit STM7-AF | - | - |  | ||

| Software zur Unterstützung der Messungen STM7-BSW |  |  |  | ||

| Software zur Unterstützung der Messungen (Panoramabilder/MIA und Bilder mit erweiterter Schärfentiefe /EFI) STM7-ASW-ME |  |  |  | ||

MIKROSKOPIEVERFAHREN

HF: (Hellfeld)

DF: Dunkelfeld

DIC: Differenzieller Interferenzkontrast

POL: Polarisiertes Licht

: Option

: Option

Bedienbarkeit

Tische, die zu Ihren Proben passen |

Häufige Probleme

| Lösungen mit STM7

|

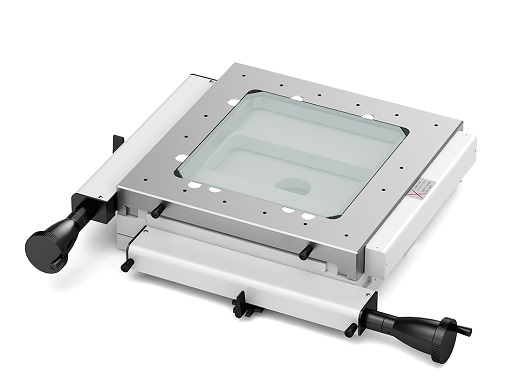

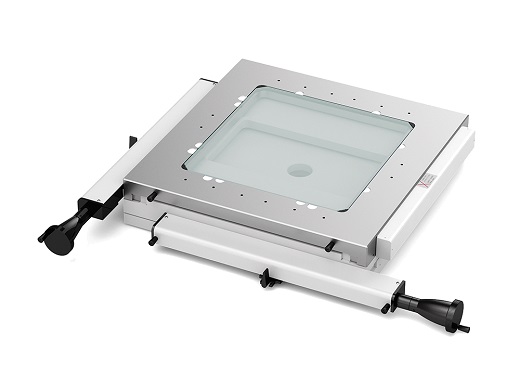

Maximaler Messhub 300 mm x 300 mmEs stehen drei Messtische mit jeweils unterschiedlichem Messhub zur Verfügung: 100 mm × 100 mm, 200 mm × 200 mm und 300 mm × 300 mm. Ganz gleich, ob Ihre Proben groß oder klein sind, wir bieten Ihnen einen Messtisch, der zu Ihrer Anwendung passt. |

STM7-CS100 |

STM7-CS200 |

STM7-CS300 |

Breite Auswahl von Vergrößerungen und Arbeitsabständen |

Häufige Probleme

| Lösungen mit STM7

|

MessobjektiveDer sehr große Arbeitsabstand der Objektive erleichtert die Fokussierung auf Proben mit hohen Spitzen und tiefen Tälern und minimiert die Wahrscheinlichkeit, dass das Objektiv die Probe berührt. Darüber hinaus ermöglicht die geringe Vergrößerung die Beobachtung großer Flächen in einer einzigen Ansicht. |

|

|

|---|

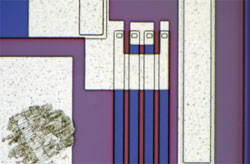

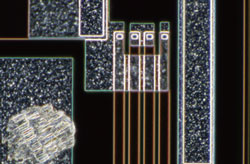

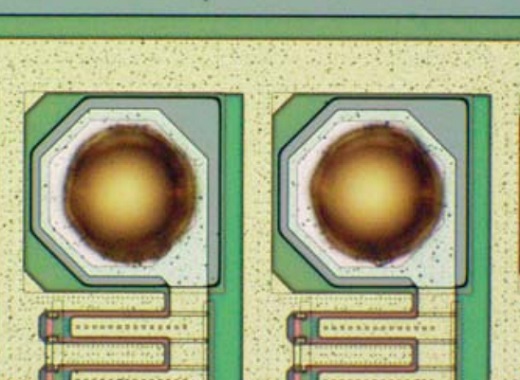

Hellfeld-Bild |

Dunkelfeld-Bild | Metallurgie-ObjektiveMetallurgie-Objektive ermöglichen eine Mikroskopie mit starker Vergrößerung und hoher Auflösung, vergleichbar mit der von Lichtmikroskopen. Darüber hinaus können diese Objektive für Hellfeld-, Dunkelfeld- und DIC-Mikroskopie verwendet werden. Klicken Sie her, um weitere Einzelheiten zu den Objektiven UIS2 zu erfahren. |

|---|

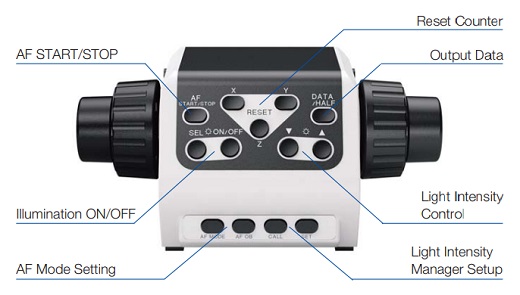

Innovative Steuereinheit ermöglicht höhere Benutzerfreundlichkeit. |

Häufige Probleme

| Lösungen mit STM7

|

SteuerungenBei der Serie STM7 übernimmt eine einzige Steuerung praktisch alle Messmikroskop-Operationen, auch Auslese-Reset, Beleuchtungssteuerung, Fokussierung und Autofokus. Aus Effizienz- und Komfortgründen kann das Gerät an einem beliebigen Ort aufgestellt und leicht mit einer Hand bedient werden. |

Für Modelle mit manueller Z-Achsen-Fokussierung: Handschalter STM7-HS |

Für Modelle mit motorgesteuerter Z-Achsen-Fokussierung: Fokussteuerung STM7-MCZ |

|---|

SteuereinheitDie Stromversorgung und die Übertragung für jede Einheit sind in einen Steuerkasten integriert. Dadurch wird der Arbeitsbereich auch dann maximiert, wenn eine Reihe optionaler Funktionen, z. B. der Fokus-Navigator, hinzugefügt wird. |

Optionen für manuelle und motorgesteuerte FokussierungEs sind manuell bediente und motorgesteuerte Fokussierungen verfügbar. Wählen Sie das Modell, das Ihren Anforderungen an Proben und Messinhalt entspricht, unabhängig von der Tischgröße. Alle Stative verfügen über eine lineare Skala für die Z-Achse, sodass eine Messung in 3 Achsen möglich ist. |

Manuell bediente Z-Achsen-Fokus-ModelleManuell bediente Modelle bieten ein ausgezeichnetes Preis-Leistungs-Verhältnis mit vertrauter Griffbedienung und erlauben eine schnelle vertikale Bewegung, wenn Prüfer Proben mit unterschiedlichen Höhen messen müssen. |

Motorgesteuerte Z-Achsen-FokussierungsmodelleDie motorgesteuerte Einheit verbessert die Bedienbarkeit und verringert die Ermüdung bei der Handhabung durch wiederholte Fokus- und Höhenmessungen. Die koaxialen Drehknöpfe für Grob- und Feintrieb bieten ein der manuellen Bedienung ähnliches Gefühl, wobei die Modelle auch mit einer Autofokus-Einheit ausgestattet werden können. |

Automatische Einstellung der Lichtstärke

|

Häufige Probleme

| Lösungen mit STM7

|

Präzise Steuerung der Lichtstärke mit quantitativer DigitalanzeigeDie Serie STM7 zeigt die Lichtstärke mit einer quantitativen Digitalanzeige an, sodass die Mikroskopie unter konstanten Beleuchtungsbedingungen durchgeführt werden kann. |

|

5X Lichtstärke 50 |

20X Lichtstärke 70 |

100X Lichtstärke 120 | Keine manuellen Anpassungen mehrDer Lichtstärkemanager kann mit dem kodierten Objektivrevolver verwendet werden. Der codierte Objektivrevolver erkennt jeden Objektivwechsel automatisch. Auf diese Weise werden die Beleuchtungsmethode und die Lichtstärke für jedes Objektiv registriert und Messungen beim Wechsel des Objektivs automatisch angepasst. Nun muss die Lichtstärke nicht mehr manuell eingestellt werden, was früher bei jedem Wechsel der Vergrößerung erforderlich war. |

|---|

Schnelle Überprüfung von Messergebnissen und Gerätestatus mit einer abnehmbaren Digitalanzeige |

Häufige Probleme

| Lösungen mit STM7

|

Schnelle, visuelle StatusprüfungDer Indikator zeigt den Gerätestatus und die Einstellungen an. Die Mindestwerte für die X-, Y- und Z-Achse können zwischen 0,1 μm und 1 μm umgeschaltet werden und die Anzeigeeinheiten zwischen mm, μm, Zoll und Mil. |

Am Stativ angebrachte Digitalanzeige |

|---|

Digitalanzeige auf einem Schreibtisch | Platzierung einer abnehmbaren Digitalanzeige nach individueller PräferenzDie Platzierung der abnehmbaren Digitalanzeige ist dem einzelnen Prüfer überlassen, sie kann am Stativ oder am Arbeitstisch befestigt werden. Werden Messungen im Stehen durchgeführ, kann die Anzeige seitlich am Stativ in fast derselben Höhe wie der Beobachtungsort angebracht werden und ist damit gut sichtbar. Beim Arbeiten im Sitzen, z. B. beim Mikroskopieren oder Messen auf einem Monitor mit einer Digitalkamera oder bei Einsatz des motorgesteuerten Z-Achsen-Fokussiermodells, werden die Digitalanzeige und die Handsteuerung einfach auf den Arbeitstisch geleget. |

|---|

Höhenmessung

Schnellere, einfachere und genauere Höhenmessung |

Häufige Probleme

| Lösungen mit STM7

|

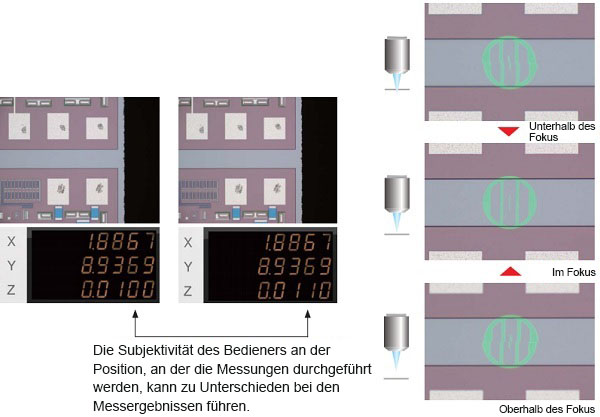

Einfaches, präzises Fokussiersystem mit hervorragender WiederholgenauigkeitDer Fokus-Navigator von Olympus erlaubt eine hochgradig reproduzierbare Höhenmessung, indem er ein Muster innerhalb des Sichtfeldes projiziert und vertikale Abweichungen identifiziert. Bei Höhenmessungen mit normaler visueller Beobachtung können geringfügige Fehler auftreten, selbst wenn der Fokus scharf zu sein scheint. Der Fokusnavigator ermöglicht jedoch Messungen durch einfachen Abgleich der Markierungen und reduziert damit die Subjektivität des Prüfers bei Messergebnissen. |  |

|---|

Schnelle und hochgenaue Höhenmessung durch Autofokus |

Häufige Probleme

| Lösungen mit STM7

|

Dedizierte Autofokus-Einheit:

|

One-Shot-ModusÄndert sofort den Autofokus in der Mitte des Sichtfeldes von grob auf scharf. |

TRACK-ModusDer TRACK-Modus verfolgt mit Autofokus die Spitzen und Täler der Probe, auch wenn der Tisch verstellt wird, sodass das Bild ständig scharf bleibt. Diese Weiterentwicklung verbessert die Effizienz von Z-Achsen-Messungen erheblich, da Beobachtungen durchgeführt werden können, ohne die Hände von den Griffen X und Y zu nehmen. |

Messunterstützungssystem

Genaue, schnelle und einfache Vermessung komplex geformter Objekte |

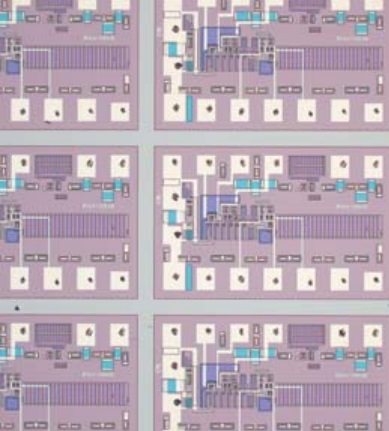

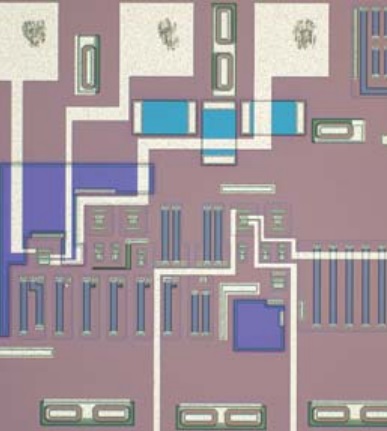

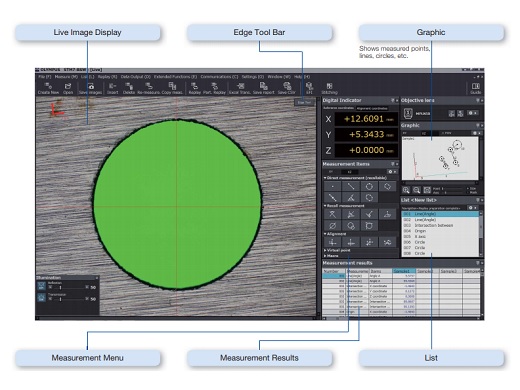

MessunterstützungssystemFür Messmikroskope ist eine scharfe und einfach zu erkennende Ausgabe auf dem Bildschirm sehr wichtig. Die Messsoftware von Olympus ermöglicht komplexe Messungen mit höherer Genauigkeit. Die Software unterstützt auch den Einsatz von Digitalkameras. |  |

|---|

Zubehör zur Erweiterung des Mikroskopie- und Messbereichs |

Codierter ObjektivrevolverWird ein codierter Objektivrevolver mit einer Digitalkamera kombiniert, lässt sich die Objektivvergrößerung während der Mikroskopie auf dem Bildschirm anzeigen und aufzeichnen. Mit dieser praktischen Funktion können bei der Erfassung einer Probe gleichzeitig Informationen über die Probe und die Vergrößerung des Objektivs aufgezeichnet werden. |  |

|---|

| STM7-FS/FußschalterZur freihändigen Übertragung von Daten, sodass die Prüfer die Messung abschließen können, ohne die Hände von den Griffen X und Y zu nehmen. |

|---|

SZ-LW61/Weißlicht-LED-BeleuchtungseinheitDiese leichte, platzsparende Konstruktion zeichnet sich durch lange Betriebsdauer und niedrigen Stromverbrauch aus. Die kostengünstige LED-Beleuchtungseinheit ist zudem frei von Flimmern und Lichtstärkeschwankungen. |  |

|---|

| SZX2-ILR66+SZX-RHS/LED-Ring-Beleuchtung + HandsteuergerätDas Handsteuergerät SZX-RHS ermöglicht die unabhängige Beleuchtung mit vier Segmenten der LED-Ringbeleuchtung SZX2-ILR66, um klare Bilder mit hoher Farbtemperatur zu erhalten. Die optimale Beleuchtung kann aus 13 Mustern ausgewählt werden. |

|---|

DrehtischZur einfachen parallelen Ausrichtung der Probe. |

STM7-RS100 |

STM7-RS200 |

STM7-RS300 |

|---|

Spezifikationen

TECHNISCHE ANGABEN ZUM STM7 (manuell bedientes Modell) |

| Manuell bedientes Modell | |||||

| Kleiner Tisch | Mittelgroßer Tisch | Großer Tisch | |||

| Mikroskopgehäuse | STM7-SF | STM7-MF | STM7-LF | ||

| Fokus | Vertikaler Verstellbereich | 175 mm | 145 mm | ||

| Maximale messbare Höhe |

120 mm (mit Messobjektiv)

175 mm (mit Metallurgie-Objektiv) |

90 mm (mit Messobjektiv)

145 mm (mit Metallurgie-Objektiv) *1 | |||

| Messauflösung der Z-Achse | 0,1 um | ||||

| Art des Z-Achsen-Triebs | Manuelle koaxiale Fein-/Grobfokussierknöpfe | ||||

| Beleuchtung | LED-Beleuchtung | Weiß: für Auflichtbeleuchtung, grün: für Durchlichtbeleuchtung | |||

| Beobachtungstubus | MM6-ETR Trinokulartubus mit aufrechtem Bild (100:0/0:100) | ||||

| Okular (FN22) | MM6-OCC10X (mit Fadenkreuz) , MM6-OC10X | ||||

| Objektive | HF (Hellfeld) |

MM6C-KMAS

Beleuchtung | |||

|

U-5RES-ESD

Objektivrevolver | |||||

|

MPLFL5X, 10X, LMPLFLN20X, 50X, 100X

Metallurgie-Objektive | |||||

| HF (Hellfeld)/DF (Dunkelfeld) |

MM6C-RLAS

Beleuchtung | ||||

|

U-D5BDRES-ESD

Objektivrevolver | |||||

|

LMPLFLN5XBD, 10XBD, 20XBD, 50XBD, 100XBD

Metallurgie-Objektive | |||||

| LED-Einheit | Farbe Weiß (Auflicht)) | MM6-ILW | |||

| Farbe Grün (transmittiert) | MM6-ILG | ||||

| Tisch | STM7-CS100 | STM7-CS200 | STM7-CS300 | ||

| Messbereich | X-Achse 100 mm, Y-Achse 100 mm | X-Achse 200 mm, Y-Achse 200 mm | X-Achse 300 mm, Y-Achse 300 mm | ||

|

Messgenauigkeit

(L: Messlänge) | (3+2L/100) μm | (3+4L/200) μm | (3+6L/300) μm | ||

| Gewichtung der Messgenauigkeit | 6 kg | 10 kg | 15 kg | ||

| Zähler | STM7-DI | ||||

| Anzahl der Achsen | Drei | ||||

| Einheit | μm/mm/Zoll/Mil | ||||

| Mindestauflösung | 0,1 um | ||||

| Steuereinheit | STM7-CB | ||||

| Handschalter | STM7-HS | ||||

| Fokussteuerung | - | ||||

| Schnittstellenkabel | - | ||||

| Schwingungsdämpfer | - | STM7-VI | |||

| Stromkabel | UYCP | ||||

| Abmessungen (B × T × H) mm | 466 × 583 × 651 | 606 × 762 × 651 | 804 × 1024 × 686 | ||

| Gewicht (kg) | 84 kg | 152 kg | 277 kg | ||

| Leistungsaufnahme |

100-120/220-240 V – 50/60 Hz

0,3 A/0,2 A |

100-120/220-240 V – 50/60 Hz

0,3 A/0,2 A |

100-120/220-240 V – 50/60 Hz

0,3 A/0,2 A | ||

*1 Bei Verwendung des großen Stativs STM7-LF/STM7-LFA kann eine Probe mit einer Höhe von max. 100 mm an einer Position mindestens 180 mm hinter der Lichtachse platziert werden.

ARBEITSABSTAND DER OBJEKTIVE

| Objektiv | 1X | 3X | 5X | 10X | 20X | 50X | 100X | ||

| Messobjektive | Serie MM6-OB | 59,6 | 76,8 | 65,4 | 50,5 | - | - | - | |

| Metallurgie-Objektive | Serie MPLFLN | Hellfeld | - | - | 20,0 | 11,0 | 3,1 | 1,0 | 1,0 |

| Serie LMPLFLN | Großer Arbeitsabstand | - | - | 22,5 | 21,0 | 12,0 | 10,6 | 3,4 | |

| Serie MPLFLN-BD | Hellfeld/Dunkelfeld | - | - | 12,0 | 6,5 | 3,0 | 1,0 | 1,0 | |

| Serie LMPLFLN-BD | Hellfeld/Dunkelfeld, großer Arbeitsabstand | - | - | 15,0 | 10,0 | 12,0 | 10,6 | 3,3 | |

SYSTEMVORAUSSETZUNGEN FÜR STM7-BSW

| Element | |

| CPU | Intel Core i3 Prozessoren mit 3 GHz oder mehr mit einer STM7-CU Kamera, ein Intel Core i5 oder gleichwertig oder höher ist mit DP23/DP28-Kameras erforderlich |

| Speicher | 4 GB oder mehr mit einer STM7-CU-Kamera, wobei 8 GB erforderlich sind und 16 GB mit DP23/DP28-Kameras empfohlen werden |

| Festplatte, freier Speicherplatz | Mindestens 100 GB Festplattenspeicher für die Installation, für die Hochgeschwindigkeits-Bilderfassung wird eine SSD-Festplatte empfohlen. |

| Grafikkarte | Grafikkarte für Auflösung 1980 x 1080 Pixel und 32-Bit-Farbtiefe erhältlich |

| Laufwerk | DVD-Laufwerk |

| PC-Eingabegerät | 2-Tasten-Maus (3-Tasten-Maus mit Mausrad empfohlen), Tastatur |

| Betriebssystem | Microsoft Windows 10 Pro/Pro für Workstations (64 Bit) |

| Webbrowser | Internet Explorer 11 |

Technische Angaben STM7 (motorgesteuertes Modell) |

| Motorgesteuertes Modell | ||||

| Mittelgroßer Tisch | Großer Tisch | |||

| Mikroskopgehäuse | STM7-MFA | STM7-LFA | ||

| Fokus | Vertikaler Verstellbereich | 175 mm | 145 mm | |

| Maximale messbare Höhe |

120 mm (mit Messobjektiv)

175 mm (mit Metallurgie-Objektiv) |

90 mm (mit Messobjektiv)

145 mm (mit Metallurgie-Objektiv) *1 | ||

| Messauflösung der Z-Achse | 0,1 um | |||

| Art des Z-Achsen-Triebs |

Motorgesteuert

| |||

| Beleuchtung | LED-Beleuchtung | Weiß: für Auflichtbeleuchtung, grün: für Durchlichtbeleuchtung | ||

| Beobachtungstubus | MM6-ETR Trinokulartubus mit aufrechtem Bild (100:0/0:100) | |||

| Okular (FN22) | MM6-OCC10X (mit Fadenkreuz) , MM6-OC10X | |||

| Objektive | HF (Hellfeld) |

MM6C-KMAS

Beleuchtung | ||

|

U-5RES-ESD

Objektivrevolver | ||||

|

MPLFL5X, 10X, LMPLFLN20X, 50X, 100X

Metallurgie-Objektive | ||||

| HF (Hellfeld)/DF (Dunkelfeld) |

MM6C-RLAS

Beleuchtung | |||

|

U-D5BDRES-ESD

Objektivrevolver | ||||

|

LMPLFLN5XBD, 10XBD, 20XBD, 50XBD, 100XBD

Metallurgie-Objektive | ||||

| LED-Einheit | Farbe Weiß (Auflicht) | MM6-ILW | ||

| Farbe Grün (transmittiert) | MM6-ILG | |||

| Tisch | STM7-CS200 | STM7-CS300 | ||

| Messbereich | X-Achse 200 mm, Y-Achse 200 mm | X-Achse 300 mm, Y-Achse 300 mm | ||

|

Messgenauigkeit

(L: Messlänge) | (3+4L/200) μm | (3+6L/300) μm | ||

| Gewichtung der Messgenauigkeit | 10 kg | 15 kg | ||

| Zähler | STM7-DI | |||

| Anzahl der Achsen | Drei | |||

| Einheit | μm/mm/Zoll/Mil | |||

| Mindestauflösung | 0,1 um | |||

| Steuereinheit | STM7-CBA | |||

| Handschalter | - | |||

| Fokussteuerung | STM7-MCZ | |||

| Schnittstellenkabel | U-IFCBL200 | U-IFCBL200 | ||

| Schwingungsdämpfer | STM7-VI | |||

| Stromkabel | UYCP | |||

| Abmessungen (B × T × H) mm | 606 × 762 × 811 | 804 × 1024 × 844 | ||

| Gewicht (kg) | 159 kg | 284 kg | ||

| Leistungsaufnahme | 00-120/220-240 V 50/60 Hz 0,6 A/0,35 A | 100-120/220-240 V 50/60 Hz 0,6 A/0,35 A | ||

*1 Bei Verwendung des großen Stativs STM7-LF/STM7-LFA kann eine Probe mit einer Höhe von max. 100 mm an einer Position mindestens 180 mm hinter der Lichtachse platziert werden.

OPTION

| Objektive | Messobjektive |

Serie MM6-OB

(1X/3X/5X/10X) |

| Fokus-Navigator | Fokus-Navigator-Einheit | STM7-FN |

| Grüne LED-Einheit | MM6-ILG | |

| Autofokus | Autofokus-Einheit | STM7-AF |

| DIC | Auflicht-Schieber U-DICR DIC | U-DICR |

| Software/Kamera*1 | Software zur Unterstützung der Messungen | STM7-BSW |

| Kamera | Digitalkamera Niedrig | STM7-CU |

| Digitalkamera Mitte | DP23-CU | |

| Digitalkamera Hoch | DP28-CU | |

| Videoadapter | C-Mount-Kameraanschluss-Tubus mit 0,5X-Objektiv | U-TV0.5XC-3 |

| C-Mount-Kameraanschluss-Tubus mit 0,35X-Objektiv | U-TV0.35XC-2 | |

| Drehtisch | Für 100 × 100 mm | STM7-RS100 |

| Für 200 × 200 mm | STM7-RS200 | |

| Für 300 × 300 mm | STM7-RS300 | |

| Neutraler Graufilter | Neutraler Graufilter (Transmission 6 %) | U-25ND6 |

| Neutraler Graufilter (Transmission 25 %) | U-25ND25 | |

| DIC | DIC/Polarisator | U-PO3 |

| DIC/Analysator | U-AN360-3 | |

| Software | MIA, EFI, optionale Software | STM7-ASW-ME |

| Fußschalter | STM7-FS | |

| Netzteil | MM6-ILPS-2 | |

| Tischmikrometer | OB-M/OB-MM | |

*1 Die unterstützten Kameras variieren je nach STM7-BSW-Version.

Version 1.3.3 oder früher: STM7-CU

Version 1.4.1 oder höher: DP23/DP28