In diesem Anwendungsbeispiel erfahren Sie, wie einzelne Schichten und die Gesamtdicke von Kraftstofftanks in der Automobilindustrie gemessen werden.

Hintergrundwissen zur Herstellung von Kraftstofftanks für Kraftfahrzeuge

Die meisten modernen Kraftstofftanks für Fahrzeuge bestehen aus einer mehrschichtigen Kunststoffkonstruktion, die in der Regel aus zwei Polyethylenschichten mit hoher Dichte (HDPE) besteht, die von einer dünnen Gassperrschicht aus Ethylenvinylalkohol (EVOH) umgeben sind. Die Sperrschicht soll das langsame Austreten von Benzindämpfen durch die Polyethylenwand verhindern. Die Dicke der HDPE-Schichten liegt normalerweise zwischen 2,5 und 5 mm (0,1 bis 0,2 Zoll), und die EVOH-Sperrschicht liegt normalerweise zwischen ist typischerweise 0,1 und 0,3 mm (0,004 bis 0,012 Zoll). Hersteller von Kraftstofftanks müssen die Dicke und die Tiefe der Sperrschicht messen.

Geräte zur Dickenmessung von Kraftstofftanks

Für die gleichzeitige Messung der einzelnen Schichten und der Gesamtdicke des Tanks dieser Anwendung wird das Ultraschall-Dickenmessgerät 39DL PLUS mit der Softwareoption Multilayer empfohlen. Mit dieser Software kann das 39DL PLUS Dickenmessgerät programmierte Einstellungen (einschließlich Schallgeschwindigkeit, Verstärkung und Echounterdrückung) für jede zu messende Schicht verwenden, um die Leistung zu optimieren. Für diese Messungen wird das Dickenmessgerät häufig mit einem M2017-RM (20 MHz) Vorlaufstreckenmesskopf verwendet. Für Unterstützung zu Geräteeinstellungen kontaktieren Sie Evident.

Typisches Verfahren zur Dickenmessung von Kraftstofftanks in der Automobilindustrie

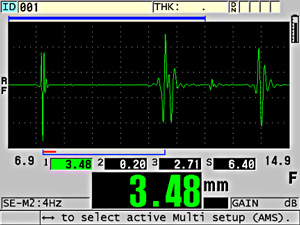

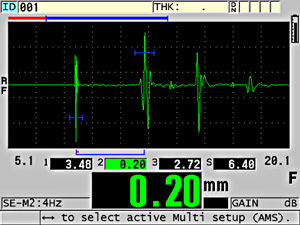

Die folgenden Wellenformen zeigen Messungen von Struktur- und Sperrschichten in einem typischen Fahrzeug-Kraftstofftank unter Verwendung geeigneter Einstellungen. Der frequenzbasierte Modus für Sperrschichten des Dickenmessgeräts wird verwendet, um die Sperrschicht anzuzeigen, wenn die Dicke unter 0,25 mm (0,010 Zoll) liegt.

Die Tiefe der Sperrschicht wird mit den Einstellungen des herkömmlichen Modus 2 gemessen, und die Dicke der inneren Polyethylenschicht wird ebenfalls im Modus 2 gemessen. Dicke Sperrschichten, über 0,010 Zoll (0,25 mm) werden auch im Modus 2 gemessen. Beachten Sie, dass aufgrund von Tiefpassfiltereffekten in der äußeren Polyethylenwand die minimale messbare Dicke der Sperrschicht normalerweise etwa 0,004 Zoll (0,100 mm) beträgt.

Das Reflexionsverhältnis an der Grenzfläche zwischen zwei beliebigen Materialien wird durch die relativen akustischen Impedanzen dieser Materialien bestimmt. Da Neuwaren und Regranulat im Wesentlichen identische akustische Impedanzen aufweisen, ist es nicht möglich, Mahlgutschichten separat zu messen. Zudem sind die angrenzenden Klebstoffschichten an die Sperrschichten häufig zu dünn und/oder ähneln zu stark deren Impedanz, um mit Ultraschalltechniken gemessen zu

werden, und können demnach nicht erfasst werden.

Äußere Polyethylenschicht

Sperrschicht (Frequenzbereichsmessung)

Innere Polyethylenschicht

Wie bei jeder Ultraschalldickenmessung hängt die Genauigkeit von der richtigen Justierung der Schallgeschwindigkeit ab. Die Justierung der Schallgeschwindigkeit muss für jedes Material durch Messen von Prüfteilen mit bekannter Dicke durchgeführt werden.