Thickness and Flaw Inspection Solutions

Olympus NDT solutions offer the latest in inspection technology. Our extensive portfolio of flaw detectors, thickness gauges, transducers, probes, and more feature the software you’ll need to help meet global inspection requirements. Our products can be used to detect and characterize defects in a range of materials—such as metals, plastics, and ceramics—helping you prioritize performance and safety. Our NDT solutions and equipment are versatile and have a variety of measurement features that allow you to carry out the necessary testing. We also aim to make our software easy to use, but if you want to learn more about the products we have available, our video tutorials provide an expert overview of the NDT equipment you’ll find on our site. |

NDT Equipment

Flaw Detectors/Phased Array Flaw Detectors

Our full range of portable ultrasonic flaw detectors (UT) provides leading-edge capabilities for locating discontinuities and other flaws. We offer a range of software, measurement features, and application-specific options for flaw detection applications that include locating and sizing hidden cracks, voids, disbands, and similar discontinuities in welds, forgings, turbines, and other structural components.

Thickness Gauges

Olympus is the leading source of thickness gauges for the accurate measurement of nearly any material. Thickness gauges include a range of features for enhanced performance. Ultrasonic thickness gauges can measure virtually any material including plastics, metals, metal composites, rubber, and internally corroded materials.

Transducers and Probes

Our high-quality probes and transducers are available in a range of frequencies, configurations, connector styles, and cable types to help you meet demanding inspection requirements. If you don’t see the probe or transducer that fits your application, ask us about custom configurations.

Industrial Scanners

Industrial XY (motorized and manual) and manual weld inspection scanners provide reliable, accurate performance in a range of heavy duty industrial applications where scanners are used to improve quality and reduce costs. Phased array scanners and accessories such as motor controllers and water pumps complete the Olympus line of scanner products.

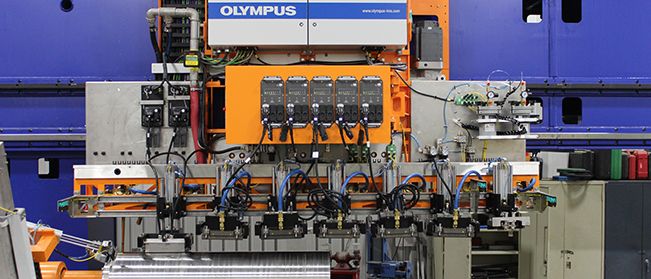

NDT Systems Instrumentation

Olympus’ industrial instruments are recognized as high-performance acquisition units and are used in our integrated inspection systems as well as by several system integrator partners located worldwide.

NDT Solutions FAQ

Why is NDT important?

Nondestructive testing (NDT) is important because it helps ensure safety and reliability across a range of industries. Using NDT equipment such as flaw detectors, you can locate and size surface and subsurface flaws and defects in material. For example, this can be done for steel used in the engineering and construction of bridges, aircraft, motor vehicles, pipelines, and more. Hidden deficiencies can cause substantial risk to safety, so using NDT to help ensure maximum performance over time is important.

How do different NDT techniques work?

Olympus specializes in five frequently used nondestructive testing (NDT) methods: eddy current, eddy current array, conventional ultrasonic, phased array, and phased array using the total focusing method (TFM)/full matrix capture (FMC).

- Eddy current: Uses electromagnetic induction to detect and characterize surface and subsurface flaws.

- Eddy current array: Provides the ability to electronically drive multiple eddy current coils for enhanced speed and data quality.

- Ultrasonic: Uses short ultrasonic pulse waves to detect internal flaws or characterize materials.

- Phased array: The beam from elements can be electronically steered, focused, and scanned with a single transducer assembly.

- TFM/FMC: With FMC, a single element is pulsed and all the other probe elements receive the reflected signals; this process repeats for all elements. TFM is the data processing method.

Can NDT be used to detect damage mechanisms and evaluate a material’s remaining life?

NDT methods can be used to identify and detect multiple damage mechanisms occurring over time, such as:

- Corrosion

- Cracking

- Stress corrosion cracking (SCC)

- Wet hydrogen sulfide (H2S)

- Common damages like blistering

- Stepwise cracking

- Hydrogen-induced cracking (HIC)

- Stress-oriented hydrogen induced cracking (SOHIC)

- Sulfide stress cracking (SSC)

- High temperature hydrogen attack (HTHA)

- And many others

For most of these damage mechanisms, NDT methods such as ultrasonic testing or eddy current testing (ECT) provide quantitative information to help calculate the remaining life of components or monitor known existing flaws over time (i.e., damage evolution).

NDT Solutions Resource Videos

Rail Inspection Using NDT Ultrasonic TechnologiesDiscover how NDT ultrasonic technologies can be used to assess efficiency and detect flaws in trains, tracks, and their materials, paving the way for improved performance. | |

Webinar – Diverse Uses of Advanced Ultrasonic Inspection Technologies for Pipeline Manufacturing, Construction, and MaintenanceThis webinar talks you through the various advantages and disadvantages of using ultrasonic inspection technologies across a range of industries. | |

Bridge Inspection Using NDT TechnologiesThis video covers how to use NDT technologies to inspect the condition of bridges. See how flaw detectors and transducers can check the construction material for subsurface defects. |