Eddy Current Probes

Olympus eddy current probes consist of the acquired brands of Nortec and NDT Engineering. We offer more than 10,000 standard and custom designed eddy current absolute probes, standard references, and accessories. This section features many of the standard eddy current probes types that are available in a wide range of diameters, frequencies, and connector styles. Olympus also offers custom eddy current probe systems to meet specific inspection requirements. There are many different types of probes available that can be designed to match the contours of a part or shaped to fit into a fixture for fast and accurate inspections. Please note that product availability varies by region. Contact your local Olympus sales office for more information. |

Eddy Current Probe Types

Loading...

Overview

Rotating Plastic Scanner Probes

The rotating plastic scanner probes section features a variety of expandable plastic-tip probes and stainless-steel backshell probes, including the SUB series, SPO-5965 series, SPO-3564 series, and standard series.

Manual Bolt Hole Probes

Manual bolt hole probe coils are positioned at right angles to the shaft direction. These probes are rotated by hand to inspect holes with the fasteners removed. Standard (fractional and metric) and custom diameters are available with either absolute or differential coils.

Spot Probes

Spot probes are used for discovering flaws both on and below surfaces. Their large coil diameter and low frequency operation are advantageous for scanning larger areas and providing an increased detectable flaw size; typically equal to one-half of the probe diameter.

Weld Probes

Weld probes are designed to inspect ferrous welds. They provide a cost-effective alternative to magnetic particle inspection, which requires the part to be prepared (cleaned) prior to inspection.

Sliding Probes

Sliding probes are specifically designed to inspect rows of fasteners. They operate in reflection mode and are used to find surface and near-surface flaws. They come in adjustable types, which are able to accommodate different fastener sizes, and fixed types, which are usually procedure specific.

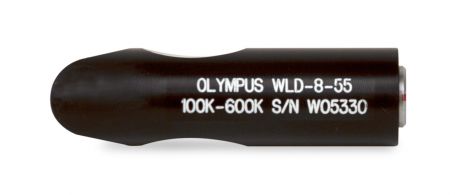

Conductivity Probes and Standards

Conductivity probes are designed for sorting non-ferrous metals and determining heat treatment condition or damage.

Right Angle Surface Probes

90° tip, stainless-steel shaft. Designed for general surface crack detection, these probes are available in a variety of lengths, and with various coil configurations, drops, and connector options.

Straight Shaft Surface Probes

Straight stainless-steel shaft. Designed for general surface crack detection, these probes are available in a variety of lengths, and with various coil configurations and connector options.

Angle Shaft Surface Probe

30° or 45° tip, stainless-steel shaft. Designed for general surface-crack detection, these probes are available in a variety of lengths, and with various coil configurations, drops, and connector options.

Flexible Shaft Surface Probes

Flexible copper shaft of these probes can be bent to various shapes. Designed for general surface crack detection, flexible surface probes are available in a variety of lengths, and with various coil configurations, drops, and connector options.

Bent Shaft Surface Probes

Bent shaft surface probes are general purpose stainless-steel probes used for surface or near-surface crack detection. They are available in a variety of sizes, and with various coil configurations and connector options.

Pencil Surface Probe

Pencil surface probes are general purpose plastic-tip probes used for surface or near-surface crack detection. They are available with various coil configuration and connector options. Pencil surface probes feature an adjustable collar for greater stability.

All Other Surface Probes

A specialized probe series including the Pencil 3551l probe, Blade probe, Plastic-Tip probe, Finger probe, and Spring-Loaded probe.

Rotating Stainless Steel Scanner Probes

The rotating stainless steel scanner probes section includes a range of all-stainless-steel probes, including the standard series and the SEU series.

All Other Scanner Probes

The other rotating scanner probes section includes a variety of specialized scanner probes, such as the Adjustable X type series, the Adjustable Y type series, the Countersink series, and the Countersink Stainless Steel series.

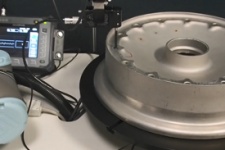

Ring/Donut Probes

Ring/Donut probes are made to fit various fastener head diameters. Their principal use is for subsurface crack detection with the fastener in place. They are available in both bridge and reflection configurations.

Cables and Adaptors

Olympus manufactures high-quality cables and adaptors to fit with all eddy current probe models.

Standards

Reference standards should be used in every application and are available in many configurations and materials.

Resources

White Papers

Tutorials

Brochures

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.