Wheel Inspection

Overview

Automated Train Wheel Inspection System (WIS)With more than a million kilometers of railway track around the world, trains are an important method of transporting goods and people. Wheel integrity is essential for safe train operation. For use on different railroad networks, train wheels are manufactured with different diameters, profiles, and weights. To help prevent railway catastrophes, manufacturing quality requirements and standards for railway wheels are increasingly demanding. |

| Optimized Mechanical platformA complete turnkey inspection station, the WIS is designed to be directly installed in the production line. Wheels are fed into the system horizontally on a rail, rolling at low speed, fully inspected using phased array ultrasonic probes, and then ejected from the system onto a rail. Main components of the system:

|

|---|

Versatile and Efficient SystemAdvantages

|

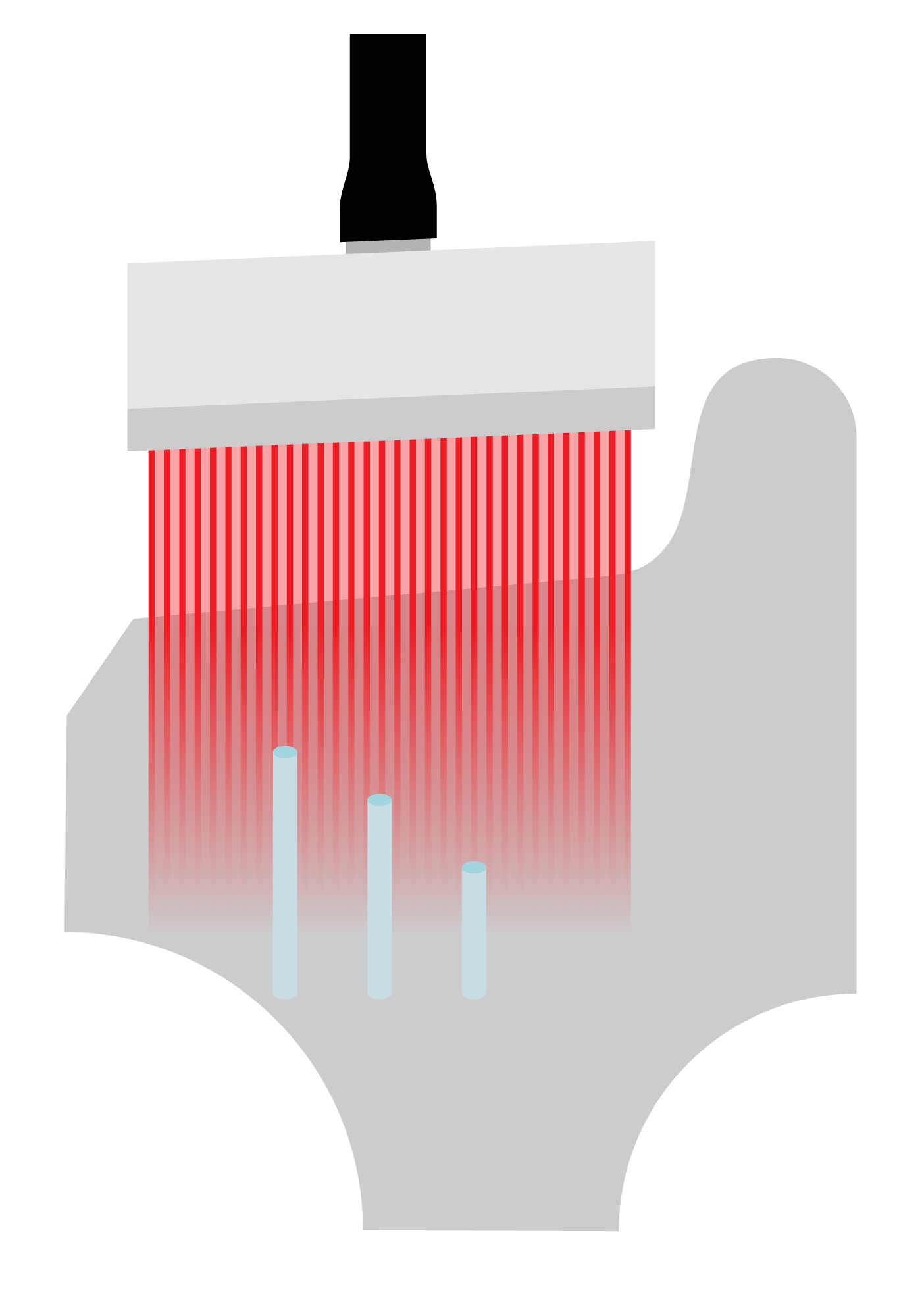

Manufacturing InspectionIn-service train wheels require periodic reprofiling. During this process, material is removed from the wheel to restore it to its original profile. When reprofiling is completed, the wheel rim is checked from the tread using a linear phased array probe before it goes back into service (Figure 3). Typically, a 5 MHz, 128-element phased array probe is used in this application. A linear scan is performed to cover the area of interest (Figure 4).

|

Software Features

RailView SoftwareRailView acquisition and analysis software is PC based and offers powerful inspection features, advanced analysis tools, and fully customizable displays. |

Software Features

|

Specifications

System Performance

|

Resources

Application NotesVideos |

Figure 3

Figure 3 Figure 4

Figure 4