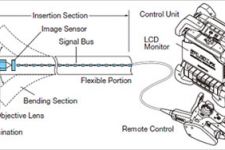

Overview

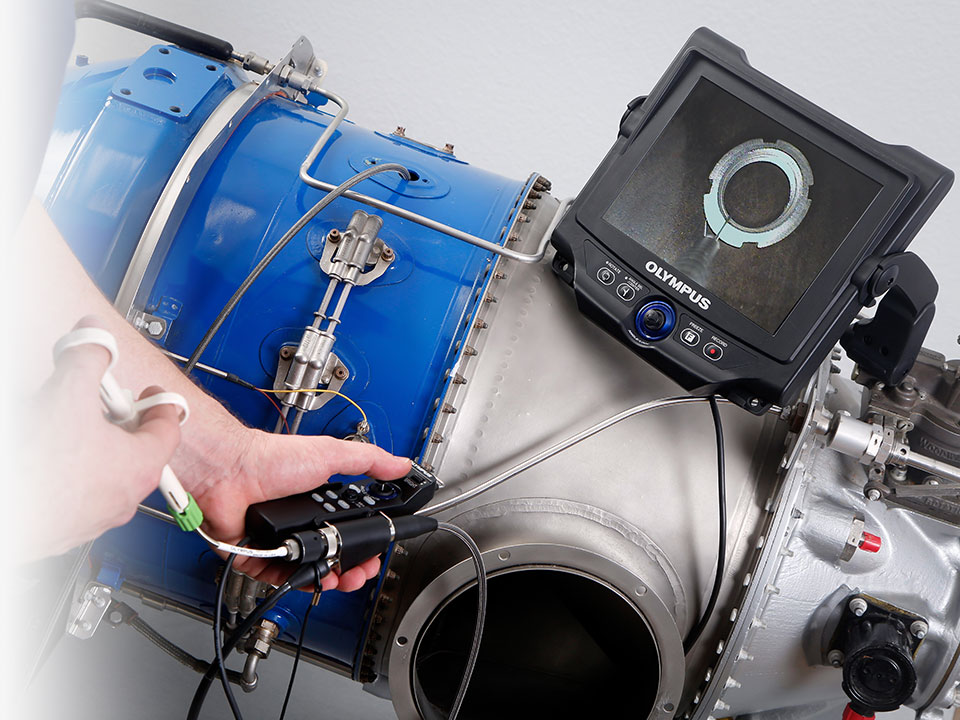

HD RVI Has ArrivedThe Expert's Choice for Visual InspectionThe IPLEX NX video borescope combines our highest-quality images with an intuitive user interface, ergonomic design, and durability for efficient inspection in nearly any environment. Its clear, bright images and powerful measurement features are built to exceed expectations. Experience IPLEX NX |  |

|

Instantly Confirm

| Set Reference Lines

| Make Confident

|

Watch 3D Modeling Video |

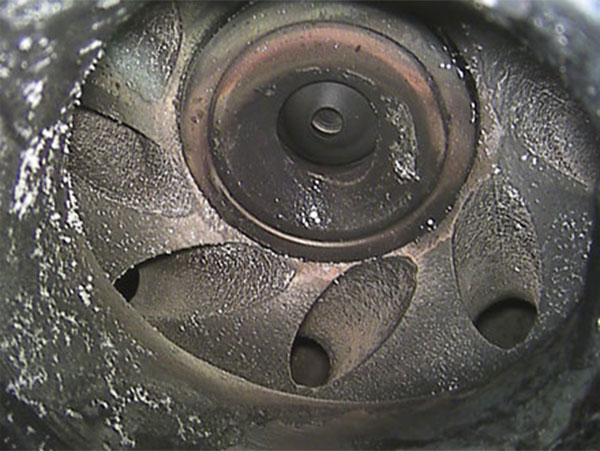

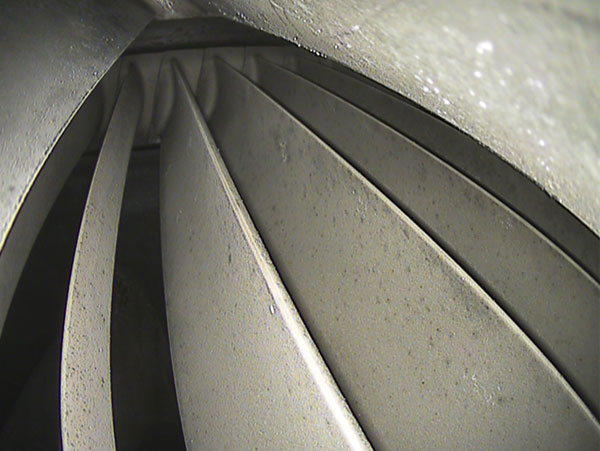

Our Highest Quality Images

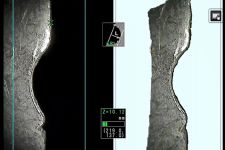

The IPLEX NX video borescope delivers crisp, high-resolution images.

|

See ClearlyExceptional image clarity enables you to see tiny defects in stunning detail. |  See MoreLaser diode illumination system is up to 4 times brighter than conventional video borescopes. |

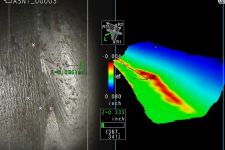

Expanded Measurement CapabilitiesEasy-to-use advanced stereo measurement offers expanded coverage for fast, efficient inspections. |

See the

| Convenient Scalar Measurement

|

Real-time Measurement with

|

Large Touch-Screen MonitorVivid touch-screen delivers clear, bright images for excellent visibility in a range of lighting conditions. |  |

Efficiency

| Efficient InspectionsThe IPLEX NX video borescope is simple to operate and user friendly. Even during long inspections, the borescope’s comfort and manoeuvrability help make the job easier. |

|---|

|

Internal Working Channel ScopeWith similar functionality and capability as a standard insertion tube, the working channel scope is a useful backup while offering the versatility to use it to detect and remove foreign object debris (FOD). Don’t get caught with a plane on the ground—add a working channel scope to your kit, so it’s there when you need it.

|  |

|---|

Internal Retrieval ToolsSix internal retrieval tools enable you to remove foreign objects and perform hook-and-drag inspections in aircraft engines. |

|

|

|

|

|

|

| Responsive TrueFeel Articulation

|

|---|

Interchangeable Scope for Multiple Jobs

|  |

|---|

|

Other Features

|

Specifications

SCOPE UNIT

| Model No | IV9435N | IV9450N | IV9635N | IV9650N | IV9675N | IV9635X1N | |

| Insertion tube | Scope diameter | ø4.0 mm | ø6.0 mm | ø6.2 mm | |||

| Scope length | 3.5 m | 5.0 m | 3.5 m | 5.0 m | 7.5 m | 3.5 m | |

| Exterior | High - durability tungsten braid | ||||||

| Tube flexibility | Uniform stiffness | Tapered Flex insertion tube with flexibility gradually increasing toward the distal end | |||||

| Optical system | Field of view | Selectable by optical adaptor. Adaptor for Stereo measurement attachable | |||||

| Direction of view | |||||||

| Illumination | High - intensity laser diode | ||||||

| Articulation section |

Articulation angle

Up/Down/Right/Left | 130° | 180° | 150° | 130° | ||

| Articulation operation | TrueFeel scope tip articulation with electronic power-assisted | ||||||

BASE UNIT

| Model No | IV9000N | ||||||

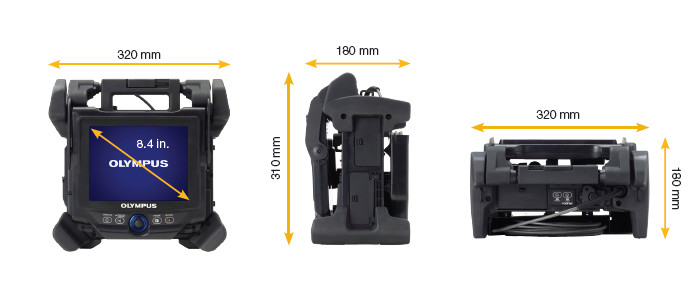

| Dimensions (W x H x D) | 320 mm x 310 mm x 180 mm | ||||||

| Weight | 5.4 kg | ||||||

|

Approx. system weight

(with battery and SDHC card) | 7.1 kg | 7.2 kg | 7.3 kg | 7.4 kg | 7.6 kg | 7.5 kg | |

| LCD monitor | 8.4-inch daylight-view, touch screen LCD, clear type | ||||||

| Input/Output terminal | Input terminal | S-Video | |||||

| Output terminal | VGA | ||||||

| USB connector | Type A connector, Version 2.0 standards | ||||||

| Power supply |

Battery: 14.8 V nominal, approx. 100-minute operating time.

AC power: 100 V to 240 V, 50/60 Hz (with supplied AC adaptor) | ||||||

| Recording media | SDHC card and USB flash memory(Still image recording only) | ||||||

| Still image recording | Resolution | H768 x V576 (Pixel) | H1024 x V768 (Pixel) | H768 x V576 (Pixel) | |||

| Recording format | Compressed JPEG format | ||||||

| Video recording | Resolution | H768 x V576 (Pixel) | H1024 x V768 (Pixel) | H768 x V576 (Pixel) | |||

| Recording format | MPEG-4 AVC (H.264) format, Windows Media Player compatible | ||||||

| Stereo measurement | Distance | Distance between two points | |||||

| Point-to-line | Perpendicular distance between a point and a user-defined line | ||||||

| Depth | Orthogonal depth/height distance between a point and a user-defined plane | ||||||

| Area/Lines | Multiple point circumference and area measurement | ||||||

| 3D Modeling | Live cross section, X/Y/Z-axis rotation, 2x Color mapping mode | ||||||

| Scalar measurement | Distance between two points based on a known measurement in the same plane | ||||||

OPTICAL ADAPTOR SPECIFICATIONS

ø4.0 mm Optical Adaptors

| AT80D/FF-IV94N | AT120D/NF-IV94N | AT120D/FF-IV94N | AT100S/NF-IV94N | AT100S/FF-IV94N | AT70D/70D-IV94N | AT50S/50S-IV94N | ||

| Optical system | Field of view | 80° | 120° | 120° | 100° | 100° | 70°/70° | 50°/50° |

| Direction of view | Forward | Forward | Forward | Side | Side | Forward | Side | |

| Depth of field*1 | 35 to ∞ mm | 2 to 200 mm | 17 to ∞ mm | 2 to 15 mm | 8 to ∞ mm | 5 to 200 mm | 3 to 150 mm | |

| Distal end | Outer diameter*2 | ø4.0 mm | ø4.0 mm | ø4.0 mm | ø4.0 mm | ø4.0 mm | ø4.0 mm | ø4.0 mm |

| Distal end*3 | 20.1 mm | 20.2 mm | 20.1 mm | 22.9 mm | 22.9 mm | 22.3 mm | 26.7 mm | |

ø6.0 mm Optical Adaptors

| AT50D/FF-IV96N | AT80D/FF-IV96N | AT120D/NF-IV96N | AT120D/FF-IV96N | AT120S/NF-IV96N | AT120S/FF-IV96N | AT90D/90D-IV96N | AT70S/70S-IV96N | ||

| Optical system | Field of view | 50° | 80° | 120° | 120° | 120° | 120° | 90°/90° | 70°/70° |

| Direction of view | Forward | Forward | Forward | Forward | Side | Side | Forward | Side | |

| Depth of field*1 | 50 to ∞ mm | 20 to ∞ mm | 7 to 300 mm | 19 to ∞ mm | 4 to 150 mm | 20 to ∞ mm | 5 to 250 mm | 4 to 250 mm | |

| Distal end | Outer diameter*2 | ø6.0 mm | ø6.0 mm | ø6.0 mm | ø6.0 mm | ø6.0 mm | ø6.0 mm | ø6.0 mm | ø6.0 mm |

| Distal end*3 | 21.3 mm | 21.3 mm | 21.4 mm | 21.4 mm | 26.6 mm | 26.6 mm | 25 mm | 31.2 mm | |

ø6.2 mm Optical Adaptors

| AT80D-IV96X1N | AT120D/NF-IV96X1N | AT120D/FF-IV96X1N | AT80S-IV96X1N | AT120S-IV96X1N | AT70D/70D-IV96X1N | AT60S/60S-IV96X1N | ||

| Optical system | Field of view | 80° | 120° | 120° | 80° | 120° | 70°/70° | 60°/60° |

| Direction of view | Forward | Forward | Forward | Side | Side | Forward | Side | |

| Depth of field*1 | 35 to ∞ mm | 2 to 200 mm | 17 to ∞ mm | 30 to ∞ mm | 8 to ∞ mm | 5 to 200 mm | 3 to 150 mm | |

| Distal end | Outer diameter*2 | ø6.2 mm | ø6.2 mm | ø6.2 mm | ø6.2 mm | ø6.2 mm | ø6.2 mm | ø6.2 mm |

| Distal end*3 | 20.6 mm | 20.6 mm | 20.6 mm | 24.4 mm | 24.4 mm | 22.7 mm | 28.3 mm | |

*1. Indicates the viewing distance with optimal focus.

*2. The adaptor can be inserted into a ø4.0 mm, ø6.0 mm and ø6.2 mm hole when it is mounted on the scope.

*3. Indicates the length of the rigid portion at the scope’s distal end when mounted.

OPERATING ENVIRONMENT

| Operating temperature | Insertion tube |

In air : -25 to 100 ℃

In water : 10 to 30 ℃ |

| Other parts |

In air : -21 to 49 ℃ (with battery)

In air : 0 to 40 ℃ (with AC power adaptor) | |

| Relative humidity | All parts | 15 to 90% |

| Liquid resistance | All parts | Operable when exposed to machine oil, light oil or 5 % saline solution |

| Waterproofing | Insertion tube (excluding IV9635X1N) |

Operable under water with viewing tip adaptor attached

Not operable underwater with stereo measurement tip adaptors IV94 series — Up to an equivalent to 5.0 m(16.5 ft) in depth. IV96 series — Up to an equivalent to 7.5 m (24.6 ft) in depth |

| Other parts | Operable in blowing rain conditions (battery compartment must be closed). Not operable under water |

MIL-STD COMPLIANCE

| The operating environment performance is confirmed by the following MIL-STD-810G and MIL-STD-461F/G. No warranty is given as to damage-free under any conditions. Please ask Olympus sales representative for details. | |

| Type | Method |

| Low atmosphere | MIL-STD-810G, Method 500.6 |

| High temperature | MIL-STD-810G, Method 501.6 |

| Cold temperature | MIL-STD-810G, Method 502.6 |

| Rain and Blowing rain | MIL-STD-810G, Method 506.5 |

| Humidity | MIL-STD-810G, Method 507.5 |

| Salt Fog | MIL-STD-810G, Method 509.5 |

| Blowing dust | MIL-STD-810G, Method 510.5 |

| Explosive Atmosphere | MIL-STD-810G, Method 511.5 |

| Vibration | MIL-STD-810G, Method 514.6 |

| Shock | MIL-STD-810G, Method 516.6 |

| Icing/Freezing Rain | MIL-STD-810G, Method 521.3 |

| Conducted susceptibility Power leads | MIL-STD-461G, CS101 (IV9635X1N, IV9435N and IV9450N only) |

| Conducted susceptibility Bulk cable injection | MIL-STD-461G, CS114 (IV9635X1N, IV9435N and IV9450N only) |

| Conducted susceptibility Damped sinusoidal transient | MIL-STD-461G, CS116 (IV9635X1N, IV9435N and IV9450N only) |

| Radiated emission Magnetic Field | MIL-STD-461G, RE101 (IV9635X1N, IV9435N and IV9450N only) |

| Radiated emission Electric Field | MIL-STD-461G, RE102 Below Deck (IV9635X1N, IV9435N and IV9450N only) |

| Radiated susceptibility Magnetic Field | MIL-STD-461G, RS101 (IV9635X1N, IV9435N and IV9450N only) |

| Electromagnetic Interference (EMI) | MIL-STD-461G, RS103 Above Deck (IV9635X1N, IV9435N and IV9450N only) |

| MIL-STD-461F, RS103 Above Deck (excluding IV9635X1N, IV9435N and IV9450N) | |

DIMENSIONS

.jpg?rev=455F)

.jpg?rev=DF90)

.jpg?rev=68DD)