35RDC Ultrasonic Composite Damage Checker

Overview

35RDC Composite Damage Checker

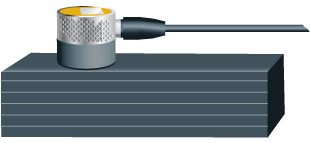

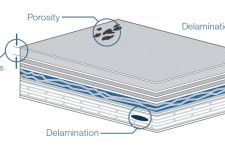

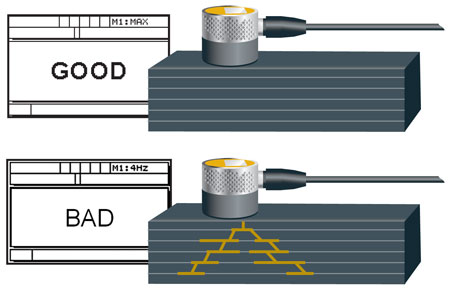

The handheld 35RDC is a simple Go/No-Go ultrasonic instrument designed to detect subsurface defects caused by impact damage on solid laminate aircraft composite structures. The 35RDC features a backlit LCD that displays the word GOOD if no subsurface damage is found or the word BAD when it detects subsurface damage. It uses an ultrasonic transducer that can be placed or scanned on the area of composite material suspected of having impact damage. Weighing only 0.24 Kg (8.5 oz.) and featuring a simplified keypad, this rugged ultrasonic instrument is easy to operate and requires minimal training. Features

|  |

Specifications

| General > Environmental IP65 compliant | Splash-proof, impact-resistant case. Sealed, color-coded keypad |

|---|---|

| General > Operating Temperature Range | -10° C to +50° C (+14° F to 122° F) |

| General > Size: (W x L x H) | 84 mm x 152 mm x 84 mm (3.31 in. x 6.0 in. x 1.50 in.) |

| General > Weight | 0.24 kg (8.5 oz) |

| General > Standard Inclusions | Wrist strap, 3 AA batteries, 5 MHz transducer, transducer cable, couplant, carrying case, rubber protective boot with neck strap, instruction manual, two-year limited warranty |

| General > Display Modes |

|

| General > Thickness Measurement Range** |

0.63 mm to 22.8 mm (0.025 in. to 0.900 in.)

** Thickness range depends on material, transducer, and surface conditions. |

| General > Material Velocity | Fixed velocity for carbon fiber aerospace composite |

| General > Transducer Frequency | 5.0 MHz |

| General > Measurement Update Rate | 20 Hz |

| General > Deviation alarm set points | Programmable +/- from calibration point. Set in advance setup |

| Power Supply > Battery | 3 AA alkaline or NiMH batteries |

| Power Supply > Operating Time | 150 hours typical battery life; 30 hours continuous with backlight on |

| Power Supply > Low Battery Indicator | Continuously indicates battery status |

| Power Supply > Battery Saver | Auto Power Off/Continuous On |

| Power Supply > AC Power Supply | Optional |

Optional Accessories

USB/ADP-115: AC-115 power supply

USB/ADP-230: AC-230 power supply

*All specifications are subject to change without notice.