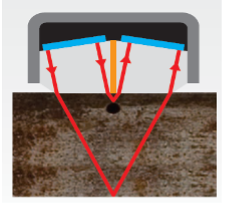

Dual Linear Array™ (DLA) probes are unique in that the transmitting and receiving arrays are mounted at an angle on a delay line that acoustically insulates the pulsing and receiving sound beams. This design reduces the amplitude of surface reflections and improves the near-surface resolution by focusing the generated beams beneath the part surface.

Our DLA probes for phased array (PA) corrosion inspection offer several advantages over dual element transducers used for conventional ultrasonic testing (UT).

Improvements include:

Options including a contoured removable delay line and irrigation are available for our DLA probes to optimize results on pipes as small as 4 inches (101.6 mm) in diameter. We also offer a high-temperature version to inspect surfaces as hot as 300 °F (150 °C). |  |

Incentive to Rewire the Dual Linear Array Probe

Thanks to its specially developed wiring, the DLA probe has proven its worth for PA inspection when used with non-PR phased array acquisition instruments. Often mounted on automated or semiautomated scanners, DLA probes achieve high-quality C-scan imaging for corrosion monitoring as well as assessing critical defects such as pitting, creep damage, and hydrogen induced cracking (HIC).

As the capabilities of phased array devices have advanced, so have the demands on probe technology. It’s these performance requirements that prompted our sensor R team to undertake designing the “pulse-receive,” or PR, model, of the REX1 DLA probe. The REX1 PR model’s wiring is configured differently than the original in order to further expand its beam firing capacity.

Advanced Ultrasonic Techniques Require Advanced Electronics

Newer advanced ultrasonic techniques such as the total focusing method (TFM) and phase coherence imaging (PCI) involve complicated firing sequences that test the limits of the original probe wiring.

Read Advantageous Applications for Phase Coherence Imaging (PCI) to learn more about this innovative imaging technique.

The electronic connections between the elements in the REX1 DLA PR model’s arrays are optimized to support the complex focal law demands of OmniScan™ X3 units with TFM and OmniScan X3 64 flaw detector with PCI and TFM. To fully exploit the imaging performance potential of TFM and PCI, it’s imperative that you choose the PR version of the REX1 DLA probe.

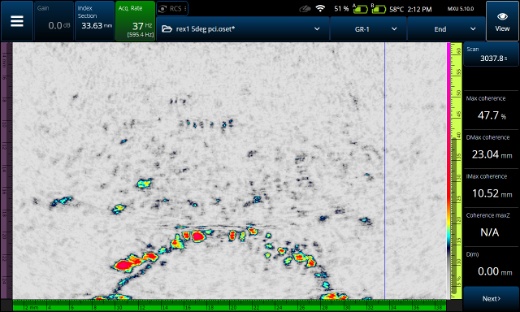

In addition to standard PA imaging, the REX1 DLA PR probe can be used to perform efficient and high-quality TFM and PCI scans, as shown in these examples of images acquired of hydrogen induced corrosion in steel.

For maximum compatibility, the OmniScan X3 series is preconfigured with the specifications of our DLA probes, making the inspection setup quick and easy. When creating a TFM or PCI scan plan, you can simply choose your DLA model from the probe list and proceed with focal law configuration directly on the instrument.

When Selecting Your REX1 DLA Model, Look for the PR

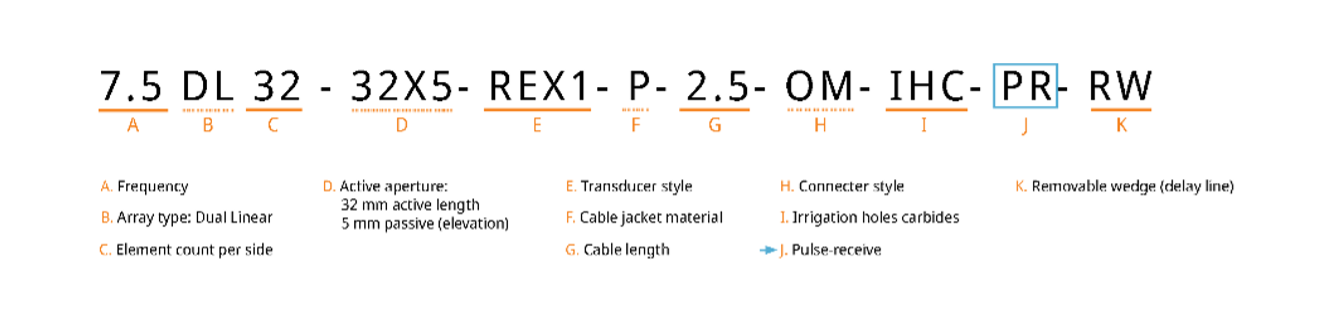

If you have an OmniScan X3 or OmniScan X3 64 flaw detector, and you want to order a DLA probe that enables you to maximize its capabilities, make sure that “PR” is in the part number.

Here’s an example:

Above is a REX1 DLA PR probe part number with a definition for each segment. The PR portion, which identifies all REX1 DLA PR models, is called out in blue.

When you’re confident about all the other probe characteristics that you need for your inspection, then all you have to remember is to look for the PR. Download this brochure to get all the ordering information.

However, if you need assistance determining what type of probe will perform best for your targeted part and defect type(s), don’t hesitate to reach out and an Evident representative. We’ll make sure you get the right probe for both your needs and your instrument.

Learn more about the capabilities of DLA probes and the OmniScan X3 series.

Related Content

TFM and Other Major Advantages of the OmniScan X3 Flaw Detector for NDT Inspectors—A Customer Review

Five Advantages of Dual Linear Array Probes for Corrosion Inspection

Bookmark This! Access Our Total Focusing Method (TFM) Resources in One Convenient Location