Corrosion Inspection Solutions

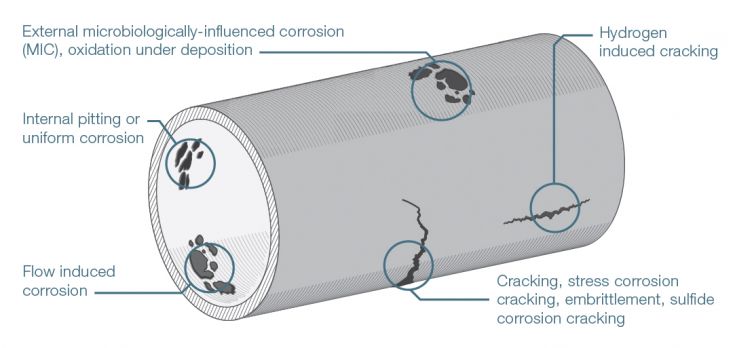

Rigorous inspection for your most critical assets

Corrosion Inspection Solutions

- Phased Array Ultrasound

- Eddy Current Array

- Ultrasound Time-of-Flight Diffraction

- X-Ray Fluorescence and Diffraction

- Conventional Ultrasound

- Conventional Ultrasound

- Remote Visual Inspection

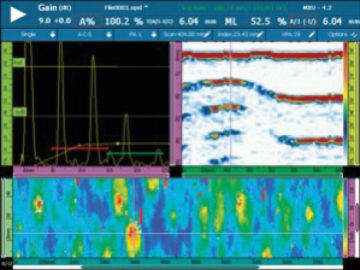

Phased Array Ultrasound

High-resolution corrosion mapping in large areas- Accurately map part thickness

- Scan very large areas quickly

- Data can be easily exported for further analysis

Learn More

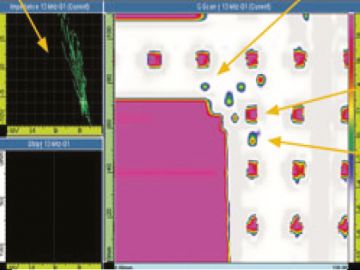

Eddy Current Array

Map corrosion below surfaces- Detect surface corrosion like stress corrosion cracking (SCC) or surface and sub-surface corrosion on aluminum

- No need to remove paint; fewer steps means time-savings

- Green method (no chemicals involved)

Learn More

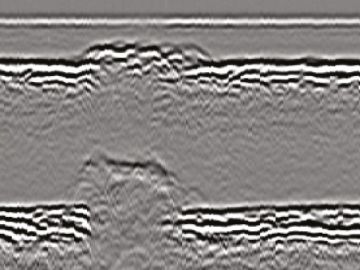

Ultrasound Time-of-Flight Diffraction

Weld root evaluation per ASME VIII Division 1 and 2 and erosion damage- Evaluate the depth and lenght of the damaged area

- Quick imaging and simple inspection

- Not sensitive to the internal orientation of damages

Learn More

X-Ray Fluorescence and Diffraction

Portable XRF and XRD- XRF provides on-the-spot material chemistry to identify whether critical components are made of the right alloy

- Portable XRD technology enables users to identify the mineralogy of corrosion scaling and the root cause to help prevent further corrosion

Learn More

Conventional Ultrasound

Corrosion under uneven surfaces using EMAT- Measure corrosion under external oxide scaled surfaces

- No couplant required

- Can be used on high-temperature surfaces

Learn More

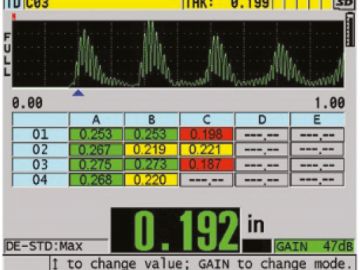

Conventional Ultrasound

Measure remaining wall thickness- Special delay lines may be used on surfaces up to 260° C (500° F)

- Use an encoded scanner to generate encoded B-scans of remaining wall thickness

- Boiler tube and internal oxide scale layer measurement

Learn More

Remote Visual Inspection

3D stereo measurement for quicker decision making- Responsive videoscopes enable visual inspection of inspect hard-to-reach welds

- Increase the probability of detection with sharp, vivid images that help make inspection fast and efficient

- Improved 3D stereo measurement capability for in-situ defect measurement

Learn More

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.