The more you learn, the more you need to grow.

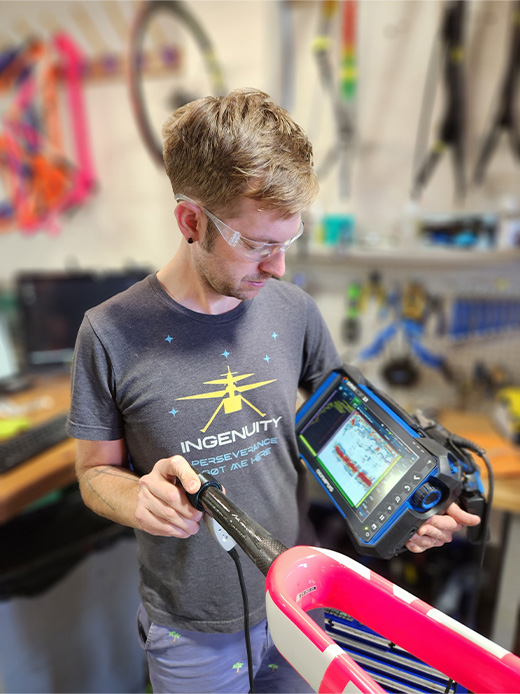

| Since our previous post on Ruckus Composites, the carbon fiber inspection and repair company has expanded its technological expertise at an impressive rate. From our conventional 45MG ultrasonic testing (UT) device through to our advanced phased array (PA) OmniScan™ X3 flaw detector, the inspection equipment it uses has undergone a meteoric progression. In this interview, Shawn Small, Ruckus Composites owner and engineer, shares the story behind this rapid evolution. He also explains how our transition to the NDE open file format has provided Ruckus with the latitude to make another extreme leap. With minimal programming know-how, Shawn is leveraging artificial intelligence (AI) to innovate custom solutions and break new ground in materials science research. Read about the journey here. |

Q: What first prompted Ruckus Composites try ultrasonic testing (UT)?

Shawn Small: It was probably 8 or 9 years ago now, I started going through the inspection techniques for composites, seeing what’s even possible, and ended up on ultrasound. We’d played with flash thermography and laser shear interferometry at this point, and all sorts of hybrid solutions, but I wanted something a little more definitive. And it seems like ultrasound is really the only consistent method out there that I’ve come across.

But we had a much smaller budget back then, we were a much smaller company. The 45MG UT thickness gauge was the only thing we could afford at the time, so it was a great introduction piece. We still have it and a 38DLP™ gauge, so a little bigger version of it. And honestly, they’re still great for what they are. They’re just easy, point and shoot, simple. You can set one up and give it to an untrained person, and they can capture the data they need quickly.

Right out of the box, it’s only a thickness gauge, but getting a few of the add-ons make it a pretty handy machine. And we can still use it, you can still detect flaws with it. It’s not as comprehensive, but you can ‘go or no-go’ something saying ‘yes, this is damaged.’

Q: What motivated Ruckus’ choice to purchase an OmniScan™ SX phased array unit?

Shawn: We knew we wanted something heavier duty, and we wanted to move into phased array. I knew a lot of the benefits of moving to that unit. It increases our confidence in our findings. That’s one of the easier things. You’re shooting so many more elements, with such higher resolution, you can really start to understand what’s going on with the composite structure a lot more.

PA data interpretation vs. UT waveform data

A waveform is useful, and if you know how to read that waveform you can get some pretty good data out of it. But it also takes a lot of work and experience to understand the width, height, and depth of a spike: what does that represent, or does it represent given the structure? Versus the phased array system, which gives us a more scientific, research-based view that allows us to really understand damage modes. With such a high resolution, it gives us a more comprehensive view of what

we’re looking at. It’s also much faster to scan something a with a phased array unit versus a single-element transducer.

Q: Why didn’t you upgrade directly to the OmniScan™ X3 flaw detector, our highest-performance PA instrument?

Shawn: We demoed an OmniScan X3 flaw detector before we bought our OmniScan SX. If I could go back in time, I honestly would have bought the X3 at the time. But it was a little overwhelming and outside of my then budget. It’s kind of like being thrown into the deep end of the pool with a million features. So, the SX was a nice steppingstone. And realistically, it still does 95 percent of what we need it to do. It captures good phased array data, it allows us to get screen views, and do all the things we need. It just feels dated in comparison. Honestly though, I still love the SX. It’s a small, light portable machine, so, there are a lot of pros to it. We keep it around and I still have my staff using it.

Q: How has using a phased array instrument changed how you operate?

Shawn: It also allowed us to step into the world of automated scanning. We build a lot of portable automated machinery nowadays, and I just plug it straight into the phased array box, first the SX or the X3 now, and just let it capture all these large C-scans, which is awesome! That kind of opened up a really big opportunity of automated scanning, because it’s saved me a lifetime of time. Now I can just press go on my machine and let it scan for 2 hours straight and come back and get the C-scan data. And I’ve scanned I don’t know how many thousands of miles of carbon-fiber tubing at this point.

Q: What phased array configurations do you use for your composite inspections?

Shawn: We use an array of high-frequency, tiny probes. Everything we scan is tiny, annoyingly so. We're using the smallest probes that are available from you folks and sensor networks of 5 millimeters by 5 millimeters in these little sixteen element probes.

A lot of the things we scan are only a foot by a foot or, a half meter by a half meter, with a complicated surface and all these tight corners. So that's where we load it into a CNC machine, and we make all of our own delay wedges that are sculpted and machined to get into some really weird spots.

We're mainly using all 10-megahertz probes for everything. The tighter pitch seems to work really well. It gives us that high-resolution data that we need to look at porosity or voids in composites.

Q: What was the tipping point? Why did Ruckus Composites decide it was time to upgrade to an OmniScan X3?

Shawn: The NDE file format, that was the number one reason. OmniPC™ software is fine, it does what it needs to do. It allows a thousand different people to look at a thousand different things in a generic way. Switching file formats to .nde enabled us to do research and analysis in way that wasn’t possible before. There’s all this analysis that we want to do, but for a company like us the file format was an obstacle. I had to export it to Excel, and then you’re stuck. Excel’s fine, but when you have so many layers in an array data file structure, it just turns into an impossibility. It was holding us back. We weren’t allowing ourselves the opportunity to really dig into a deeper analysis from an automated standpoint.

So now with the NDE file format, we’re writing all our own software structures to do just bulk automated analysis. Now when I perform an automated scan of miles of tubing, I don’t look at it. I just let the computer look at it. It highlights regions of interest and do pre and post event, which is you know if something mysterious happens, and it goes, “hey is this damaged?” I just load the two files, hit compare and it highlights regions of interest. I’m not going to say it’s perfectly working, but that’s the intend of how were trying to make it work, at least on the software side.

Q: How smooth was the transition to customizing your data analysis using the programming languages of the .nde file format (HDF5 and JSON)?

Shawn: In certain crowds, people use massive formats like this all the time—in an open-source Linux based world— they look at it and say ‘yeah, this is no problem.’ They don't know what any of the data means, but as far as opening the data and manipulating it, they can have something up and running in 20 minutes. Whereas I’m using ChatGPT to create my own software, and it just spits out a draft analysis software in around 30 seconds.

I’ve asked it to ‘help me analyze these parts of this data set,’ and it gives good enough generic information. Because at the end of the day it’s just data analysis and just numerical data on the energy, just energy location and regionalities. It’s not perfect, but it works well enough to at least get the ball rolling. I can't write software, but I can have AI write software.

“I can't write software, but I can have AI write software.”

Q: How do you foresee leveraging this newfound flexibility to further Ruckus Composites’ objectives?

Shawn: We’re trying to use it to expand our repair opportunities because it's one of the biggest growing markets in the composites industry. Infrastructure repair is a massive problem and especially as the automotive industry gets more into composites as well. Everyone is still kind of scratching the surface right now.

There's going to be this massive need in the automotive world for experts and machines. Maybe for on-site diagnostics or in every auto body shop, I'm not sure. For us, it’s like looking into a crystal ball asking what the future holds for us as we pivot more and more into the specialty field of NDT of composite structures.

What does the future hold for us? I don't fully know because the composites industry is still kind of in its teenage years. It’s still trying to figure itself out, where we're going to go. Materials science is changing so fast, so we'll continue to expand on our material science capabilities. I really enjoy that world and getting to understand why damage exists.

Q: Is it this desire to learn that’s the driving force behind your rapid technological progression?

Shawn: As you keep scratching away and hitting a new wall, you think ‘well, now we need another piece of machinery to see what it can tell me.’ If you're somebody like me that loves learning more and wants to keep growing, it's a natural progression.

We could have stopped years ago at the 45 MG and put ourselves in this corner, saying ‘this is what we do.’ But, for a person interested in the world or interested in material science, that's really important. The OmniScan X3 allow us to view the unknown.

Q: Why is exploring the unknown aspects of composites through your research so important?

Shawn: We love doing research because composites are kind of this new materials science frontier. Still! I mean they’ve been around for 70 years, but we don’t know a lot about them. We don’t know what the damage modes are, we don’t know really what’s going on from a manufacturing defect standpoint.

Whether it’s our green energy goals or infrastructure goals, or aerospace or automotive, composites are transformative. But there is still just so much to be learned, so having this file format will allow us to kind of unlock a deeper material understanding in a way. Being able to do more of a research focused ultrasound analysis, it's going to be huge leap forward for the material science community. I really think it has the opportunity to unlock such a deeper understanding of failure modes in composites and build a better safer tomorrow.

Learn more about Ruckus Composites’ research.

Related Contents

FAQs about the Open File Format NDE

Ruckus Composites Inspects Thousands of Bikes with One Ultrasonic Thickness Gauge

Poster Download: Composite Inspection Solutions