If inspecting and maintaining large reciprocating internal combustion engines (RICEs) is part of your job, you may have read our recent blog post. It delved into the evolution of borescopes to video borescopes and their application for RICE inspections. This post, the second in our RICE series, will focus on practical concerns—for example, what you need to know to select the right video borescope for large engine inspections. I will also offer some helpful tips to achieve optimal inspection efficiency.

What to Look for in a Video Borescope

When you are shopping for a video borescope for large engine inspection applications, look for the following specifications and features to make sure that the equipment will meet your needs:

- Insertion tube length of at least 2 m (6.6 ft)

- Probe diameter of 6 mm (0.2 in.)

- LED light source

- Durable construction

- Two optical tips for a large field of view (FOV) and optimal focus:

- 1 side-facing far focus (AT120S/FF) scope tip for an initial overview of the cylinder

- 1 forward-facing near focus (AT120D/NF) scope tip for detailed inspection

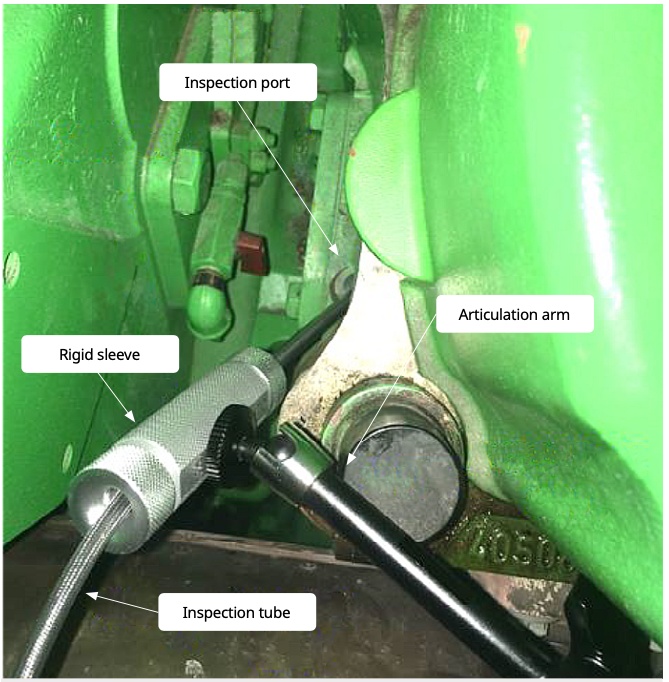

It’s also important to consider the image stability and scope movement. One approach to make sure that your probe is stabilized is to use a rigid sleeve. Installing a rigid sleeve on your insertion tube can help keep your images clear. It also reduces the risk of damage to your scope by preventing it from hitting the cylinder’s internal surfaces.

Helpful Tips about Borescope Tip Articulation

In terms of scope movement, the type of articulating tip you choose has a big influence on your ability to control your scope once it’s inserted. There are four types of articulation—categorized by the direction or directions in which the probe tip can bend—they include one-way, two-way, four-way, and joystick style. The joystick-controlled probe tip can be manual or motorized. A motorized joystick provides precise, smooth, and responsive movement, with easily adjustable speed.

IPLEX GX/GT articulating tip touch-screen control

When choosing a video borescope for RICE inspection, it’s important to select a device that is versatile and convenient. Our IPLEX™ GX/GT video borescopes feature responsive TrueFeel™ articulation controlled by a motorized joystick or via the touch screen. They are also durable and easily switchable, coming in lengths from 2 m (6.6 ft) up to 10 m (32 ft) and diameters including 4 mm (0.01 in.) and 6 mm (0.02 in.). This capacity to alternate between different scope lengths and diameters enables one modular videoscope system to perform a multitude of tasks and makes it suitable for a large variety of engine models and sizes.

To achieve the optimal configuration for your borescope, schedule an on-site demonstration with one of our product experts. They’ll be happy to discuss with you the many options available and help you get set up. Get in touch here.

Cylinder Inspection Check List for Video Borescope Operators

Using a borescope to inspect an engine is easier than you might expect. The main steps are (1) insert the probe into the cylinder, (2) inspect the components, and (3) remove the probe. Here are a few best practice recommendations from our remote visual inspection (RVI) team:

- Before you begin, make sure the engine is off and completely cooled. This helps avoid damage to your borescope as well as personal injury. Also, check that you have the correct optical tip for your inspection and that everything is clean and ready for crisp, high-definition imaging. When you’re ready, remove all the spark plugs or access port plugs for all of the cylinders that you intend to inspect.

- Next comes the fun part, inserting the scope. Using a rigid sleeve initially, insert the probe into the cylinder. The rigid sleeve reduces the chance of oil contamination and probe damage. Once inside, it’s important that the piston is positioned at the very bottom of the cylinder. This enables you to visualize the largest extent of the cylinder walls. To do this, you can observe the piston with the video borescope and then crank the engine manually until the piston

is correctly positioned. This is easily accomplished using the IPLEX Image Share app.

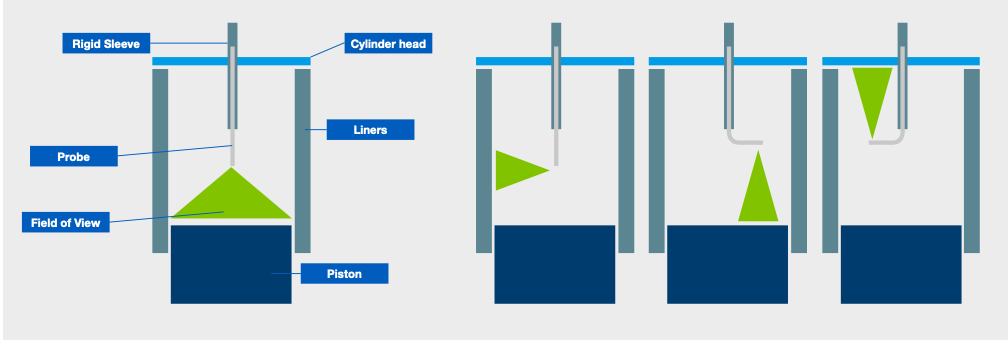

Using a side-facing optical tip to obtain an overview of the cylinder - Now it’s time to perform and record your inspection. It can be a real advantage to perform a general inspection using a side-facing optical tip since it gives you an overview of the cylinder walls, piston, valve deck, and valves (as illustrated). If you find any cracks, corrosion, or scoring, you can then swap to a direct-facing optical tip for more detailed images.

- Retract the scope and repeat! Once you’ve finished inspecting a cylinder, unlock the probe articulation and remove the probe slowly and gently. Then perform the same procedure again until all the cylinders have been inspected.

Maintaining and Caring for Your Video Borescope

To keep your video borescope in top shape, make sure to clean the optical tip after each use to remove stains and oil or water residue. For information on how to clean optical tips and the insertion tube, watch our free Inspection 360 webinar Protect Your Investment—Maintain and Care for Your IPLEX™ Videoscope.

Image Recording and Reporting to Facilitate Preventative Maintenance

At the end of the inspection, a borescope report is generated enabling a detailed analysis and assessment of the condition of the engine. This is an important reference for future inspections and a reliable record of the performance and life expectancy of your equipment. In this way, borescope inspections help to keep large engines in proper working condition and avoid expensive, time-consuming, and unnecessary maintenance and repairs.

Related Content

Examining the Reciprocal Relationship between RICE Maintenance and Borescopes

Webinar: Borescope Inspection of Diesel and Gas Generators

Webinar: Videoscope Maintenance, Care and Troubleshooting

Webinar: Inspection with Long Videoscopes—Technology and Best Practices