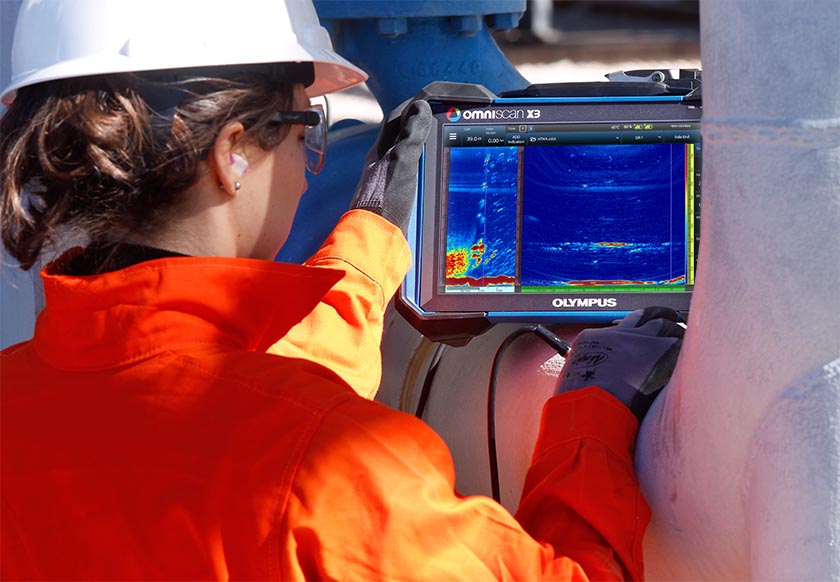

When examining a part for flaws, it’s easy for inspectors to fall prey to self-doubt. Making the wrong call can have major impacts in terms of time and money. A flaw characterization that overestimates the severity could mean undertaking a costly excavation or repairs without cause. When the severity is underestimated, it could result in a catastrophic failure. The pressure to be right weighs heavily on their shoulders.

Pushing the Envelope of TFM Processing

The OmniScan™ X3 flaw detector’s sharp, high-resolution images give inspectors the imaging data they need to feel more confident in their calls. Thanks to the X3 flaw detector’s full matrix capture (FMC) and total focusing method (TFM) technology, flaws are more accurately represented in the part. The instrument’s powerful TFM processing is pushed even further through an advanced feature called the “envelope.”

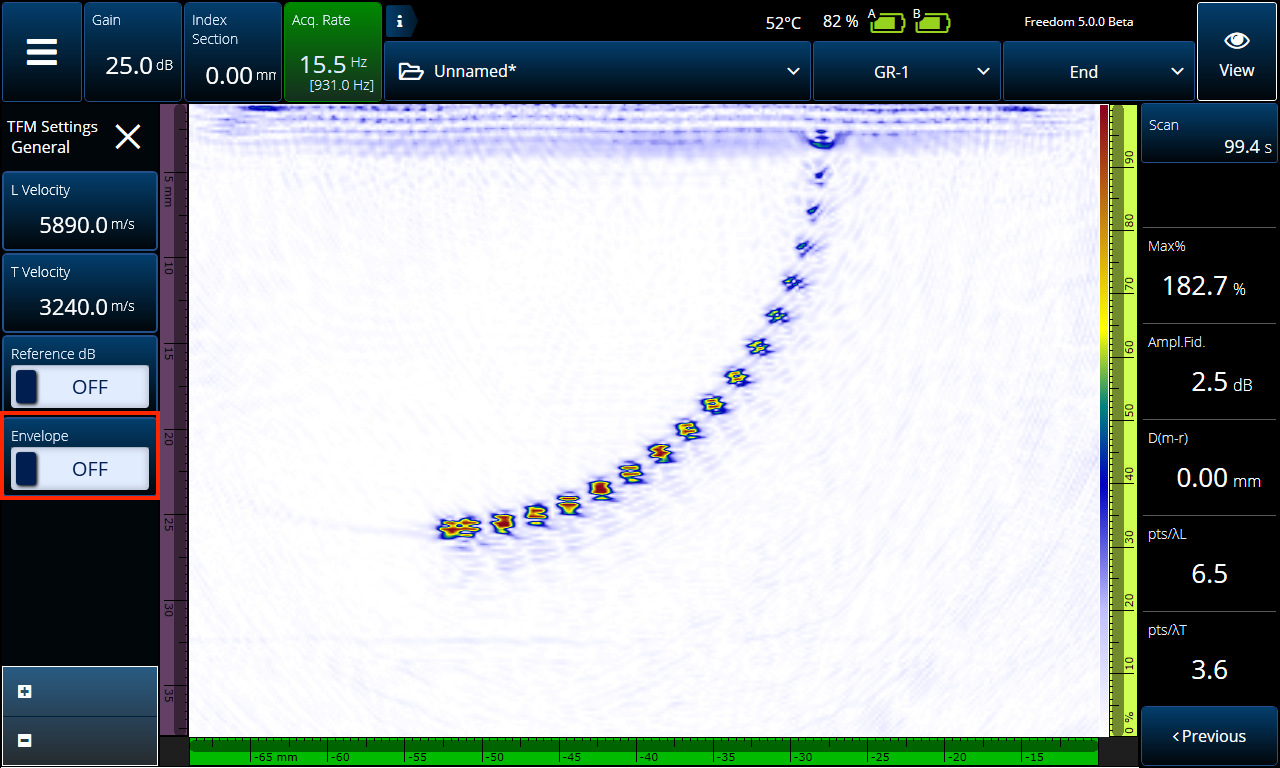

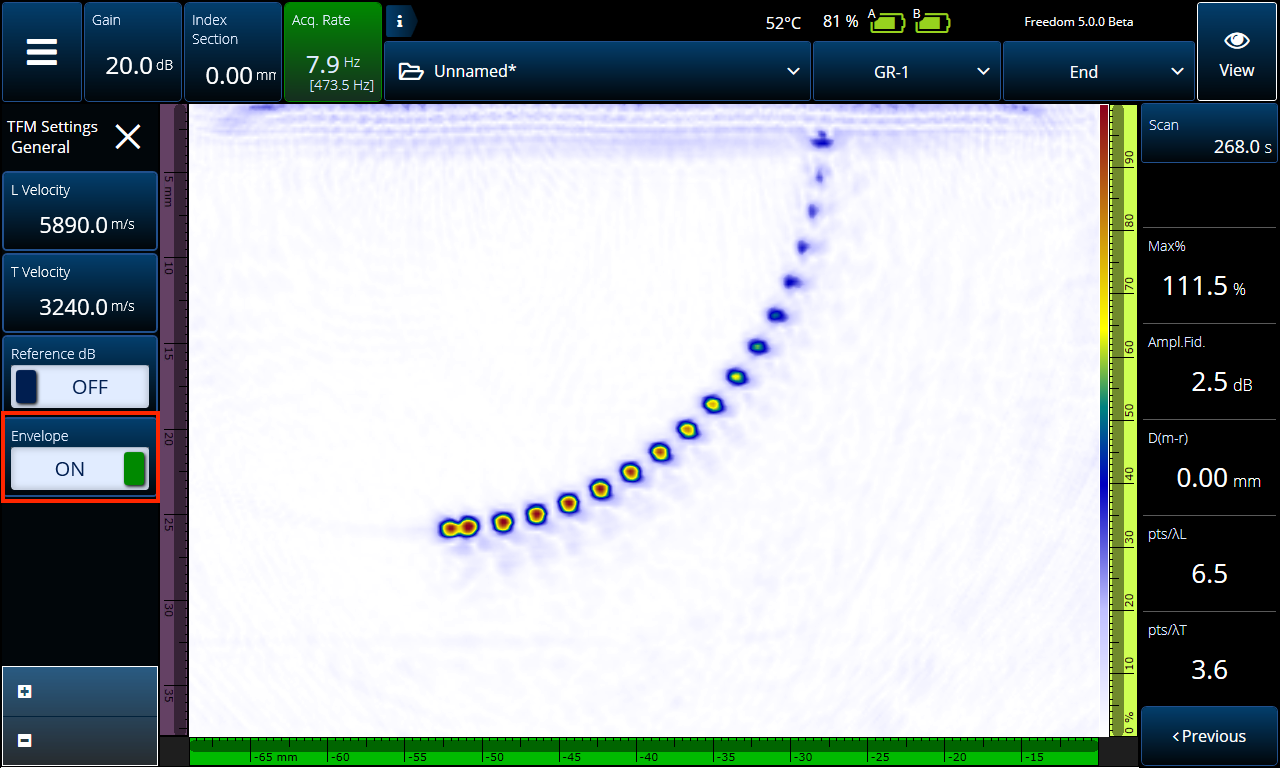

When the envelope is turned on, the OmniScan X3 software’s TFM algorithms compute the norm of an analytic TFM image (read more on how this is done in this white paper). This process helps ensure the measured maximum amplitude is more robust. In the resulting image, the shapes and sizes of flaws are easier to characterize.

Envelope OFF—The oscillations in the representation of flaws make proper characterization difficult.

Envelope ON—the TFM image is clearer and sharper, the flaws amplitude is increased and varies smoothly, and no data is lost.

If the TFM Envelope Image Is So Much Better, Why Turn It Off?

Once you see just how much the envelope improves the OmniScan X3 image, you may wonder why an inspector would opt not to use it. In my opinion there are two main reasons—I’ll start with the one that’s more easily solvable and explain the second reason later.

The first reason is performance related. The extra processing power required to compute the TFM envelope compared to the standard TFM decreases the display rate. Consequently, the acquisition rate is decreased, slowing down the instrument’s scanning speed.

But there is a work-around. With a couple minor adjustments to the TFM grid resolution and the points per wavelength (“pts/λL” for longitudinal waves and “pts/λT” for transverse waves) settings, the acquisition rate can be increased so it’s even faster than that of an equivalent quality standard TFM image.

Keep the Envelope Image without Sacrificing Your Acquisition Rate

Because the envelope processing is so powerful, the grid resolution is less consequential than with standard TFM, so even when it is reduced (less fine), the image doesn’t suffer. When the grid resolution is lowered, the number of grid points per wavelength (the pts/λ) decreases accordingly. Since less processing power is required for the coarser grid, the acquisition rate speeds back up, by more than double in some cases.

Envelope ON with a coarse grid resolution setting—this TFM grid has 2.9 pts/λL. The result is an increased PRF (or Acq. Rate), but no significant distortion of the image.

Usually in ultrasonic testing (UT), the higher the number of points per wavelength, the better the resolution and the better the image, but the performance of the TFM envelope shatters this notion. Even after reducing the grid resolution and the pts/λ, the high image quality offered by the envelope is maintained. Read on to find out why.

The TFM Envelope’s Influence on Amplitude Fidelity and Grid Resolution

The points per lambda (pts/λ) reading is an important factor in preserving an acceptable amplitude fidelity value. Inspection codes, such as the ASME’s new TFM appendix, require that the amplitude fidelity remains steady at around two decibels (dB) or lower.

Without the envelope, a ratio of around 7.8 pts/λ reliably preserves the two-decibel 2 dB amplitude fidelity variation, which results in a fine grid resolution. When the envelope is on though, the safe ratio to ensure the minimal amplitude fidelity required for detection purposes is around 3.8 pts/λ.

Confidence in the TFM Envelope Comes with Experience

The simple adjustment to the grid resolution makes it possible to benefit from the TFM envelope and still achieve a high acquisition rate. But there is still one hurdle to overcome, which is the second reason that I mentioned why some inspectors may choose not to use the envelope: TFM is a newer technology they may be unfamiliar with, and the envelope is an even newer innovation. It may take some experimentation of their own to finally be convinced of the envelope’s capability.

It’s important to remember that no information is lost. On the contrary, the signal response is reinforced using the TFM envelope since it removes signal oscillations in the image, which is not only a superfluous artifact from the acoustic origin of the image, but is actually detrimental for standard sizing procedures.

TFM Envelope Consistently Provides Truer Images of Flaws

In our own experimental testing, time and again, the envelope enhances the TFM image so that the shapes and sizes of flaws are easily discernable. There’s a notable advantage for applications involving flaws that are usually too small to see and difficult to characterize with standard phased array, such as high-temperature hydrogen attack (HTHA).

Example of TFM image of early stage HTHA acquired by the OmniScan X3 flaw detector with the envelope processing turned on

HTHA, also known as hot hydrogen attack, is an insidious corrosion that can develop gradually in steels that are exposed to hydrogen at high temperatures, such as refinery or petrochemical tanks or pipes. Using TFM imaging, inspectors can confirm their suspicions that HTHA is present in its early stages so measures can be taken to avoid failure.

Like with Most Revolutionary Technologies, Seeing Is Believing

When inspectors are given the opportunity to see the envelope in action on real-life samples, we think the empirical evidence will be undeniable. Like with most claims of extraordinary improvements, people are skeptical until they see it with their own eyes.

Contact your local Olympus representative to get more details on the envelope feature and our innovative TFM solutions. Or, check out https://www.olympus-ims.com/en/phasedarray/omniscan-x3/ to find out more or fill out the Request a Demo form.

Related Content

Top 3 FMC/TFM Enhancements of the New OmniScan X3 Flaw Detector Explained

White paper: Use of the Total Focusing Method with the Envelope Feature

Get In Touch