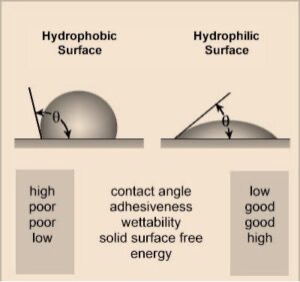

In goniometry, the contact angle refers to the angle formed at the intersection of a solid surface and a liquid droplet placed on that surface. It is a crucial parameter used in surface science and materials characterization to understand the wetting properties of surfaces. The contact angle provides information about how well a liquid spreads or wets a solid surface.

The contact angle is influenced by various factors including surface roughness, surface chemistry, and the surface energy of the solid and liquid. Different contact angles can signify different wetting behaviors such as hydrophilic (low contact angle, high wetting) or hydrophobic (high contact angle, low wetting) surfaces. Goniometry is the measurement and analysis of these contact angles.

Industries that Use Goniometry to Measure Contact Angles

Many industries use goniometry to measure contact angles on their products or equipment. Here are some examples:

- Nanotechnology

- Semiconductors

- Textile and fiber

- Polymers and plastics

- Insecticides

- Oil and gas

- Hard disk drives

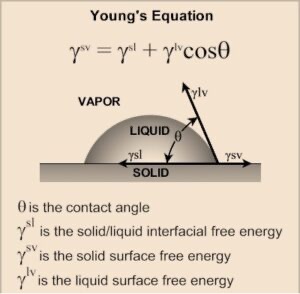

Young’s Equation

Young’s equation is used to describe the interplay of the forces of cohesion and adhesion and to calculate surface energy.

A drop with a contact angle greater than 90 degrees is hydrophobic. This situation is characterized by poor wetting, weak adhesiveness, and a low solid surface free energy. A hydrophilic drop has a modest contact angle. This state indicates improved wetting, adhesiveness, and surface energy.

Types of Contact Angle Measurements

Static Contact Angle

The static contact angle, also known simply as the contact angle, refers to the angle formed between the tangent line to the liquid surface at the point of contact with a solid surface and the solid surface itself. It is a measure of the wetting behavior of a liquid on a solid surface when the liquid droplet is at equilibrium, meaning there is no change in the size or shape of the droplet over time.

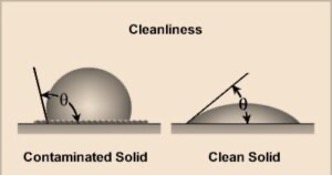

Contact angle is frequently used to assess cleanliness. Organic pollutants inhibit wetting and increase contact angles on hydrophilic surfaces. Contact angle normally decreases as wetting improves and surface energy increases as a surface is cleansed and treated to eliminate impurities.

Contact angle is frequently used to assess cleanliness. Organic pollutants inhibit wetting and increase contact angles on hydrophilic surfaces. Contact angle normally decreases as wetting improves and surface energy increases as a surface is cleansed and treated to eliminate impurities. The static contact angle can also be affected by surface roughness.

A dynamic contact angle measurement is any contact angle measured on a moving drop. This includes, but is not limited to, tilting plate contact angle measurements, volume addition and subtraction, and time-dependent research.

Time-Dependent Dynamic Studies

Researchers frequently monitor the contact angle over time to investigate the effects of absorption, evaporation, and more unusual phenomena such as the Cassie to Wenzel transitional states. Other time-dependent research examines how contact angle changes over time as environmental conditions (such as temperature and humidity) change. In some circumstances, the drop is altered by the addition of a chemical that increases or decreases surface tension.

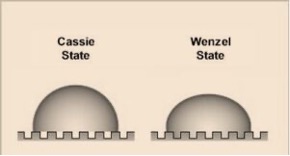

Many scholars have been studying the Cassie and Wenzel states in recent years in order to better comprehend superhydrophobicity. In a Cassie state, a drop lies on top of asperities, with air gaps beneath it, as depicted in the image below.

Tilting Plate Method

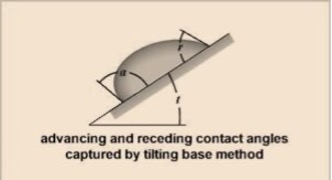

The tilting plate method captures the contact angles measurements on both the left and right sides of a sessile drop while the solid surface is being inclined typically from 0° to 90°. As the surface is inclined, gravity causes the contact angle on the downhill side to increase.

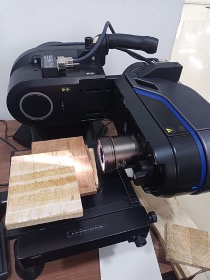

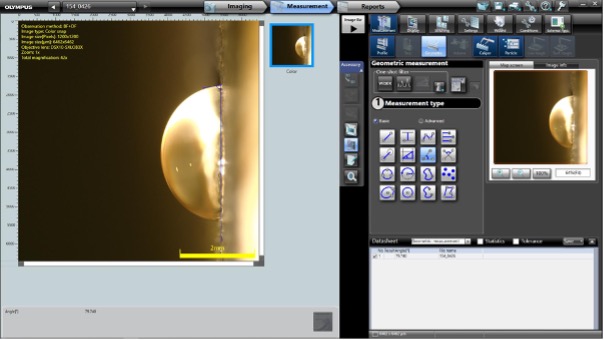

Measuring the Contact Angle with a DSX1000 Microscope

Investigating the contact angle of a wooden surface with coatings

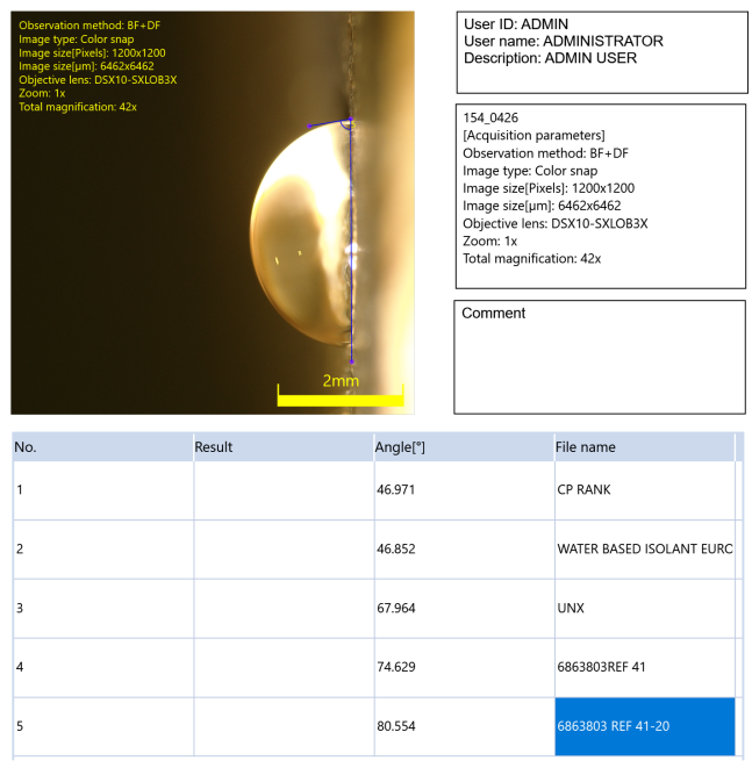

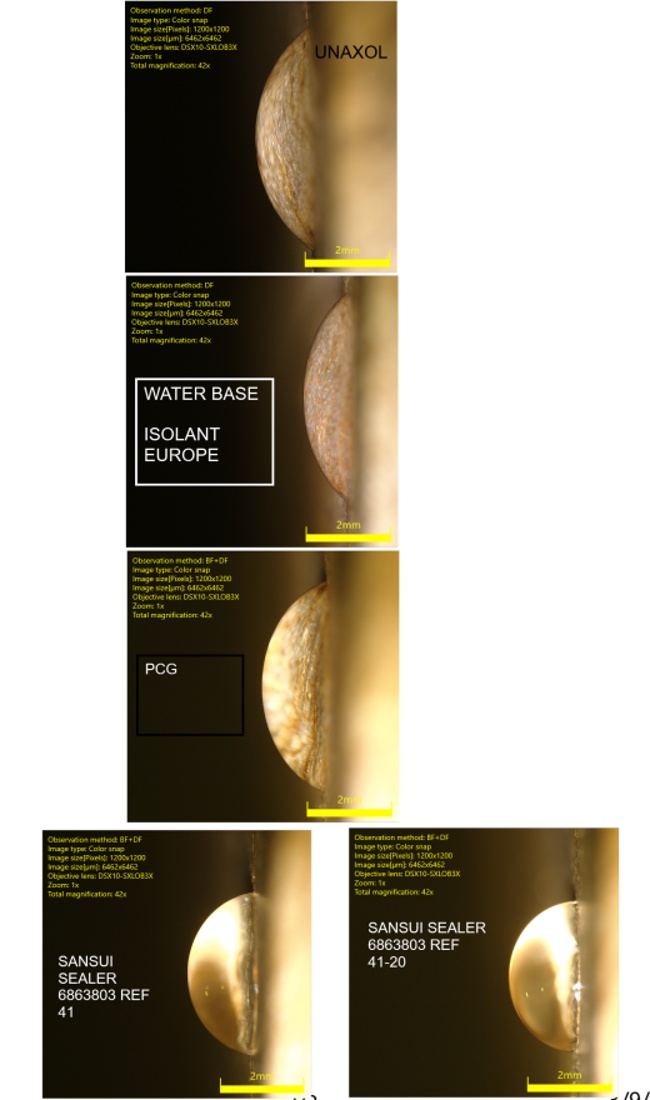

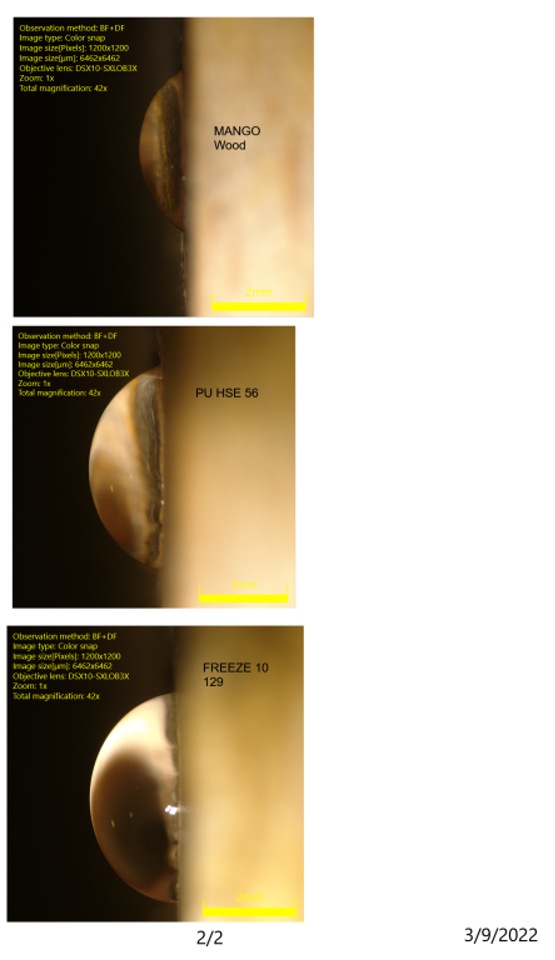

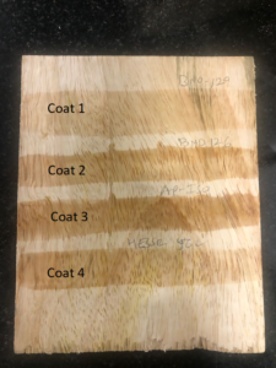

The contact angle of water on various coatings was measured using a DSX1000 microscope tilt frame with a 3x objective.

The DSX1000 system’s powerful software enables easy measurement of contact angle and surface roughness. Here we are focusing on contact angle.

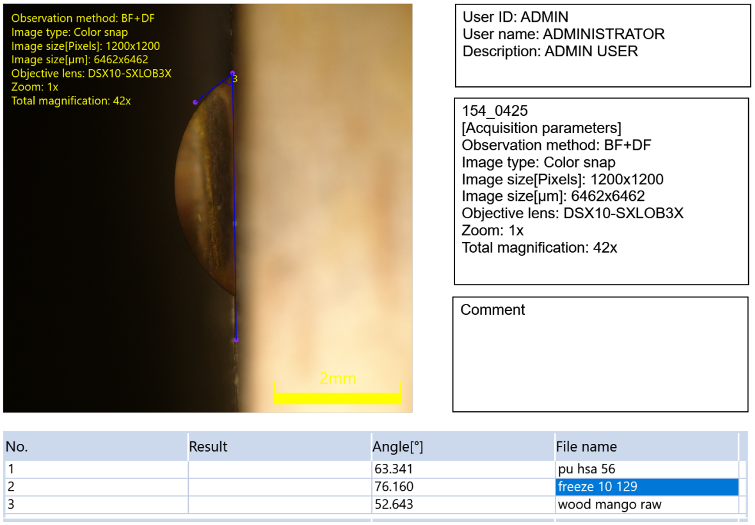

Measurement of contact is as follows.

We can deduce from the above results that the changes in contact angle values are dependent on the coating, which reflects the relative strength of the liquid, solid, and vapor molecular interactions.

We also investigated the contact angle on raw mango wood and the contact angle after coating.

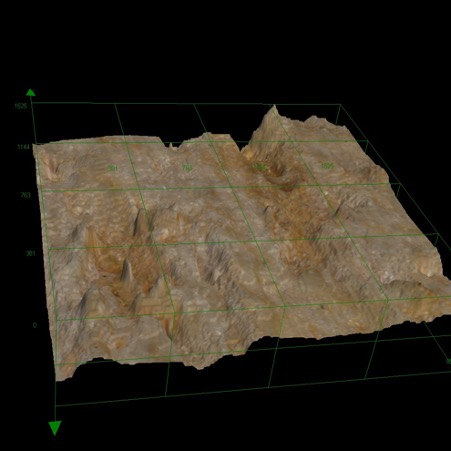

Extended Measurement Capability: Surface Roughness

Our DSX1000 microscope is also capable of measuring surface roughness of wood before and after coating.

The standard Ra and Sa parameters of line profile and areal roughness can be evaluated from the 3D image captured by the microscope.

Portions of this content have been adapted from “Olympus DSX1000 Microscope a Contact Angle Goniometer.” originally authored by Gyanesh Singh, Application Specialist at IR Technology Services Pvt. Ltd. For the original piece, please refer to www.irtech.in/uncategorized/olympus-dsx1000-microscope-a-contact-angle-goniometer/

Related Content

Detecting Manufacturing Defects on Semiconductor Wafers Using a Digital Microscope

Using a Digital Microscope for Precise Burr Measurement on Injection-Molded Products