Sistema di ispezione della saldatura a attrito

Panoramica

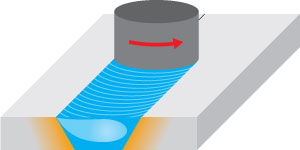

Sistema di ispezione della saldatura a attrito (FSW)Negli ultimi decenni, vi è stato un aumento significativo nel lancio dei razzi. I serbatoi di carburante usati per lanciare i razzi nello spazio sono costruiti di grandi componenti cilindriche saldate insieme mediante la saldatura a attrito (FSW - friction stir welding). L'FSW rappresenta un processo di giunzione allo stato solido che utilizza uno strumento cilindrico rotante per riscaldare e combinare due pezzi di metallo leggero nell'area giunta. Per evitare il verificarsi di problematiche legate alla sicurezza, la saldatura deve essere ispezionata in diverse direzioni per il rilevamento di vari tipi di difetti come mancanza di penetrazione, kissing bond, tarli, cavità, difetti della radice della saldatura e difetti della base della saldatura. Olympus ha sviluppato uno speciale sistema di ispezione robotico per le saldature a frizione. |

Tipi di difetti nella FSWL'FSW ha diversi vantaggi rispetto ai metodi di saldatura convenzionali, permettendo inoltre di evitare dei tipi di difetti creati dalle operazioni di raffreddamento con liquidi. Poiché si verificano dei difetti addizionali a causa di temperature insufficienti o di condizioni di saldatura questi difetti devono essere identificati e dimensionati in modo preciso. | |

Difetti naturaliLe saldature a frizione possono presentare diversi difetti come: difetti da interruzione dell'adesione del materiale su ogni lato della saldatura (denominato anche "kissing bond"), difetti longitudinali "a tunnel" e difetti da mancanza di penetrazione. Inoltre a causa del processo di saldatura a frizione i difetti possono essere orientati in modo casuale nella saldatura. |

Vista schematica del processo produttivo FSW. |

Difetti per la taraturaGli intagli longitudinali, trasversali e obliqui situati sui diametri interni ed esterni sono usati come riferimenti durante la procedura di taratura. I fori laterali (side-drilled hole) sono inoltre usati per creare la curva del guadagno corretto in funzione del tempo (TCG) la quale tiene in conto l'attenuazione del segnale nel materiale. |

Difetti orientati in maniera casuale generati durante il processo produttivo. |

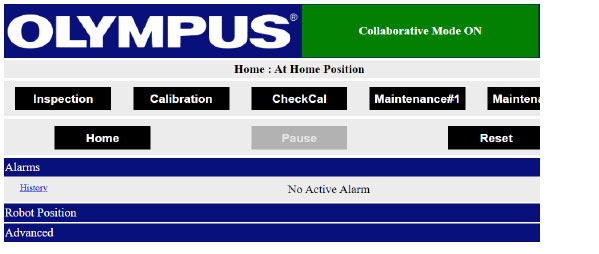

| Piattaforma d'ispezione roboticaIl sistema FSW è una stazione di ispezione completa e all'avanguardia progettata per essere direttamente installata nella linea di produzione. Le saldature di grandi serbatoi cilindrici per il carburante vengono sottoposte a ispezione mediante il Cobot (Collaborative robot). Il Cobot posiziona la testata di ispezione e il serbatoio viene ruotato fino al momento in cui la saldatura circonferenziale viene ispezionata. Il serbatoio viene quindi spostato e il ciclo si ripete per la saldatura successiva. Componenti principali del sistema:

|

Software di gestione delle parti mobili e di acquisizioneSoftware di gestione delle parti motrici per un'operatività del sistema semplificata:

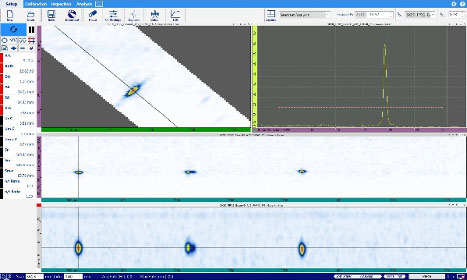

Software WeldSight™ per l'acquisizione e l'analisi dei dati:

|   |

Sistema versatile e efficienteVantaggi

|