STM7-BSW

Panoramica

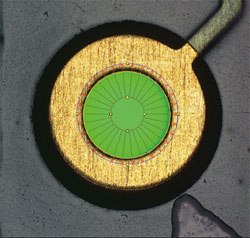

Il software di supporto delle misure STM7-BSW per le misure dei microscopi incrementa l'efficienza delle ispezioni. È possibile acquisire e visualizzare immagini, realizzare osservazioni e misure, oltre a creare report nella stessa schermata.

- Misure più precise, veloci e semplici di oggetti con forme complesse

- Acquisizione di immagini chiare e nitide per misure a alta precisione attraverso una linea completa di fotocamere

- Posiziona il campione e inizia la misura: nessun allineamento in parallelo richiesto

- Registrazione delle procedure di misure ripetute

- Eliminazione della soggettività nelle misure mediante pratiche funzioni

- Creazione di report personalizzabile

- Funzioni di acquisizione avanzate

Veloce e precisa misura di oggetti con forme complesse

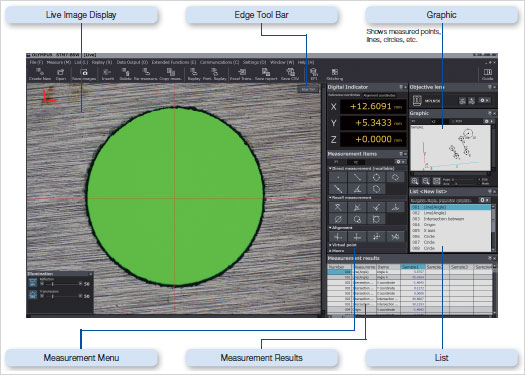

È essenziale vedere chiaramente e facilmente la schermata dei risultati del microscopio per la misura. Questo software è stato creato per questo scopo: facilitare la realizzazione di misure complesse con grande precisione. Il software inoltre permette di sfruttare appieno le camera del microscopio digitale.

Interfaccia STM7-BSW con campione

Acquisizione di immagini chiare e nitide con le nostre camera per microscopi digitali

Alte prestazioni con veloce schermata live

DP28

| DP23

|

Eccellente convenienza con un elevato rapporto prezzo-prestazioni

STM7-CU

|

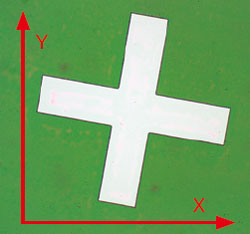

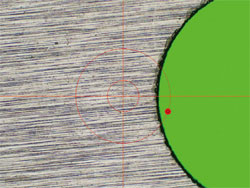

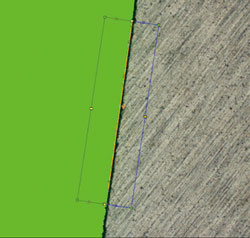

Posiziona il campione e inizia la misura: nessun allineamento in parallelo richiesto

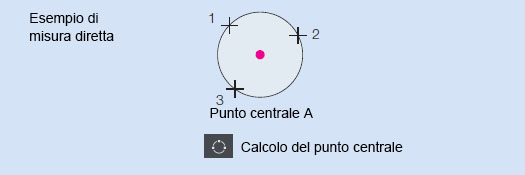

Misura diretta

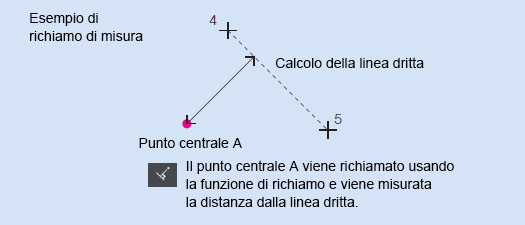

| Richiamo delle misure

|

Misura di punti virtuali

| Misura di allineamento

|

Asse originale |  Nuovo asse |

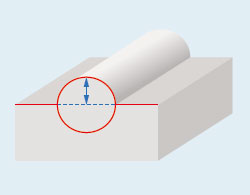

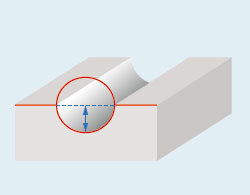

Misura del piano XZ

| I microscopi di misura convenzionale misura il piano XY direttamente dalla parte superiore.Tuttavia, in risposta alle richieste degli utenti, ha integrato una funzione di misura del piano XZ nell'STM7-BSW per permettere la misura di sezioni trasversali con visione dalla parte laterale. Attualmente si sono semplificate le misure che in precedenza risultavano complesse come: le misure dei raggi per le sezioni verticali di oggetti emisferici oppure le misure delle profondità di scanalature con le basi curve in rapporto alla linea di riferimento. |

Misura R di un campione emisferico |  Misura dell'altezza di una scanalatura dalla base alla linea di riferimento |

Registrazione delle procedure di misure usate abitualmente

Registrazione macro

La procedura di allineamento e altre procedure di misura usate frequentemente possono essere combinate e assegnate a un singolo pulsante macro, eliminando la necessità di iniziare dal principio ogni volta che il microscopio viene configurato.

Ripetizione della misura

| Le misure possono essere facilmente ripetute in base a un flusso di lavoro registrato semplicemente inserendo il movimento del tavolino e le coordinate in risposta a un messaggio del software. Questa funzione può essere usata per eseguire ripetutamente la stessa misura nello stesso campione o differente versioni dello stesso campione. |

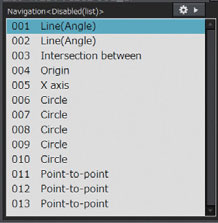

Navigazione del punto di misura per la ripetizione della misura

|  | Questa funziona visualizza la direzione e la distanza al punto di misura successivo, contribuendo a ridurre il disorientamento dell'operatore. Inoltre la funzione elimina la necessità di verificare ogni volta il punto di misura successivo nel diagramma, velocizzando il flusso di lavoro dell'operatore attraverso una serie di misure ripetute. |

Pratiche funzioni per l'eliminazione della soggettività di misura

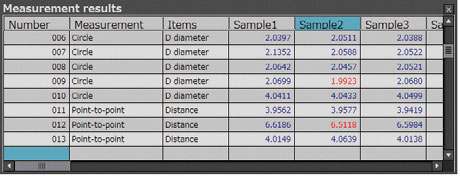

Rilevamento automatico dei bordi

Questa funzione permette il rilevamento dei bordi del campione e automaticamente acquisisce e misura le relative coordinate. Di conseguenza, non è più necessario definire le coordinate, minimizzando la soggettività. Inoltre il Rilevamento automatico del bordo integra un timer che consente di acquisire le coordinate in un momento predefinito e supporta l'uso di un interruttore a pedale che permette all'operatore di concentrarsi sulle misure senza dovere togliere le mani dalle manopole di regolazione del tavolino.

Rilevamento automatico del bordo all'interno del cerchio |  Rilevamento del bordo automatico multi-punti |

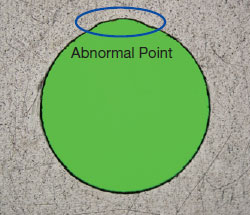

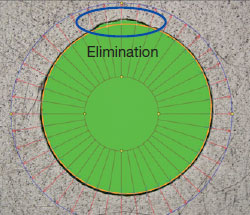

Eliminazione di punti anomali

Bave metalliche e altri punti anomali possono essere esclusi automaticamente durante il rilevamento dei bordi. Questo permette un calcolo uniforme dei valori di misura, indipendentemente dallo stato del campione. I punti esclusi in quanto considerati anomali possono inoltre essere visualizzati sulla schermata con diversi colori.

Campione con punto anomalo. |  Eliminazione di punto anomalo |

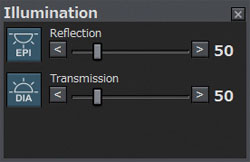

Controllo dell'illuminazione

| L'intensità luminosa del microscopio può essere mantenuta attraverso un preciso controllo del software. Le impostazioni dell'intensità luminosa possono inoltre essere salvate quando si registra un flusso di lavoro per la ripetizione della misura, permettendo l'esecuzione delle misure nelle stesse condizioni della ripetizione della misura e del rilevamento automatico dei bordi. |

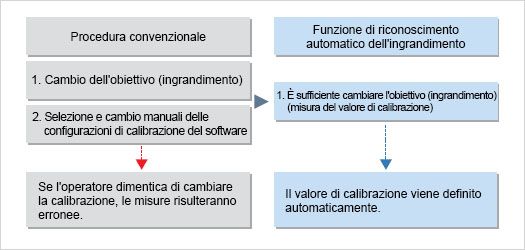

Riconoscimento automatico dell'ingrandimento (opzionale, solamente con la configurazione del revolver codificato)

Utilizzando il revolver codificato, i valori di calibrazione definiti precedentemente vengono automaticamente richiamati quando si cambia l'obiettivo. Questo permette di avere la sicurezza che viene utilizzata una scala ottimale.

Funzioni di acquisizione avanzate

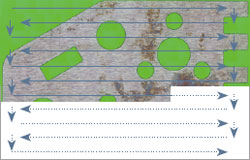

Opzionale Multiple Image Alignment (MIA)

È possibile affiancare immagini multiple per acquisire una singola immagine di un'ampia area a alto ingrandimento. Visto che le immagini sono affiancate in base alle coordinate, il sistema è in grado di produrre delle immagini altamente affidabili.

|  |

Opzionale Immagine a fuoco esteso (EFI)

La funzione EFI è efficace per l'ottenimento di immagini a fuoco per l'intero campione con forme complesse e irregolari. Permette di generare una singola immagine con punti focali allineati in tutte le posizioni.

Vengono elaborate in modo semplice delle immagini multiple attraverso diversi punti focali in varie posizioni, spostandosi sull'asse Z, o usando il modello motorizzato per la composizione automatica delle immagini.

|  |

Specifiche tecniche

Requisiti di sistema dell'STM7-BSW

| Elemento | Configurazioni di sistema |

|---|---|

| CPU | Processori Intel Core i3 da 3 GHz o superiore con una camera STM7-CU; un processore Intel Core i5, equivalente o superiore con le camera DP23/DP28 |

| Memoria | 4 GB o superiore con una camera STM7-CU; 8 GB o superiori (16 GB consigliati) con le camera DP23/DP28 |

| Spazio disponibile nel disco rigido |

100 GB o più per l'installazione

Disco SSD consigliato per l'acquisizione di immagini a alta velocità |

| Scheda grafica | Scheda grafica disponibile per una risoluzione 1980 x 1080 e 32 bit di colori |

| Lettore | DVD |

| Dispositivo di input PC | Mouse con 2 tasti (si consiglia mouse con 3 tasti e un rotella) Tastiera |

| Sistema operativo | Windows 10 Pro/Pro per workstation 64 bit |

| Browser web | Internet Explorer 11 |

* Microsoft Office da 32 bit o 64 bit 2013/2016/2019/2021/365 (SAC) sono supportati.

Una volta che le coordinate sono misurate e calcolate possono essere usate nuovamente per delle misure successive. Questo permette di non svolgere due volte la stessa operazioni, permettendo un flusso di lavoro più efficiente.

Una volta che le coordinate sono misurate e calcolate possono essere usate nuovamente per delle misure successive. Questo permette di non svolgere due volte la stessa operazioni, permettendo un flusso di lavoro più efficiente. Intersezioni, punti centrali, lunghezze e diversi altri tipi di misure possono essere realizzati tracciando linee e cerchi, i quali possono essere definiti come punti di riferimento sulle immagini acquisite di campioni.

Intersezioni, punti centrali, lunghezze e diversi altri tipi di misure possono essere realizzati tracciando linee e cerchi, i quali possono essere definiti come punti di riferimento sulle immagini acquisite di campioni. L'origine e l'asse delle X sono definite in rapporto al campione, permettendo la misura del campione anche quando non è allineato con il tavolino.

L'origine e l'asse delle X sono definite in rapporto al campione, permettendo la misura del campione anche quando non è allineato con il tavolino.