Microscopy and image analysis are used in a wide range of materials science and metallurgical applications—from incoming goods inspection to quality control and failure analysis. As a microscope manufacturer with more than a century of optical experience, we’re always developing new ways to improve metallurgical inspection workflows.

For instance, our new PRECiV™ software enables you to upgrade any manual microscope into a comprehensive imaging and measurement platform for a wide variety of materials. The software can control a range of devices that work for your inspection setup:

- Microscope: All Olympus industrial conventional or stereo microscopes, including their coded functions

- Nosepiece: Olympus motorized nosepieces

- Camera: Olympus digital microscope cameras

Here are seven ways that this simple setup can speed up your metallurgical image analysis and inspection:

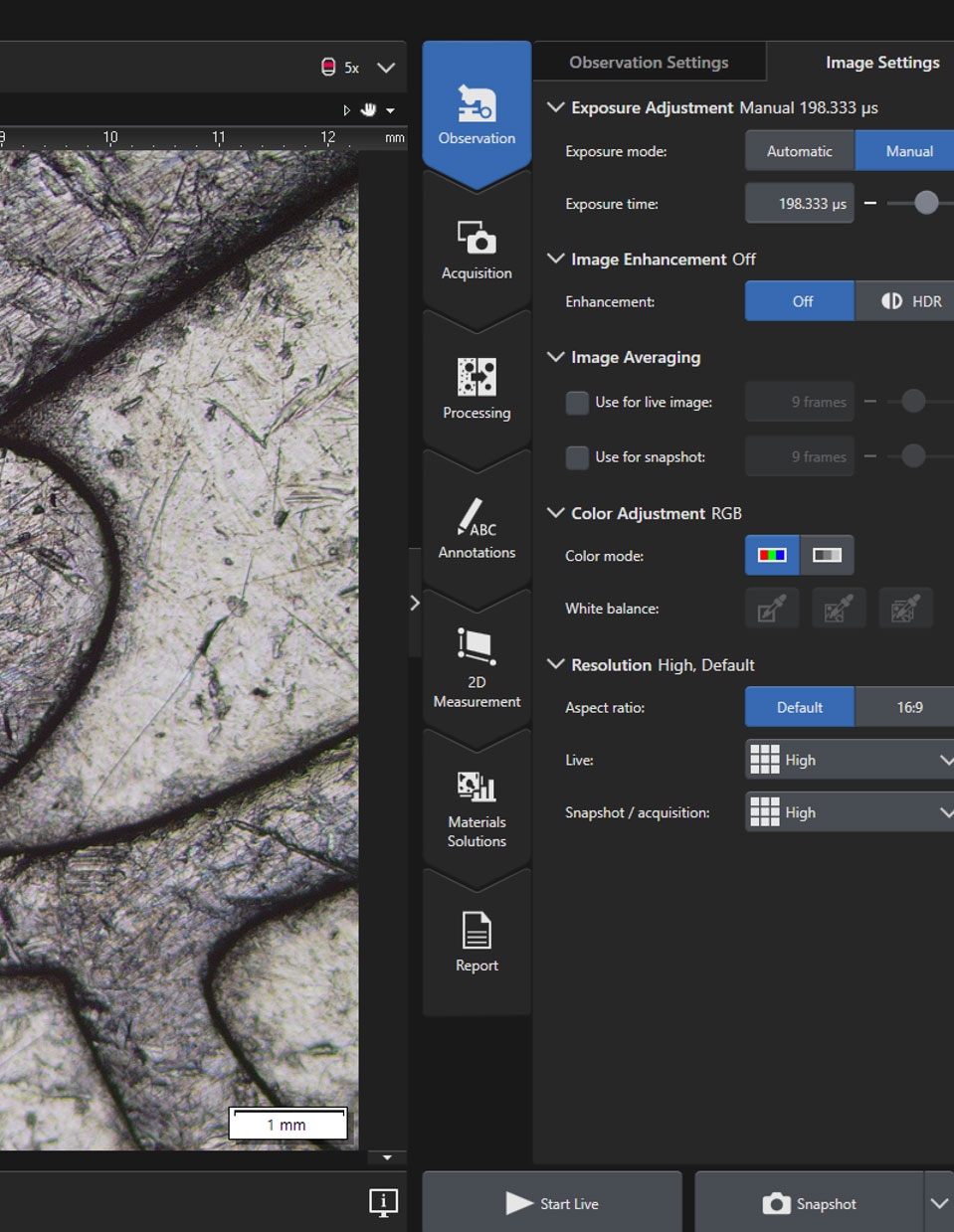

1. Features a tidy interface with user-friendly tools.

First, the software is easy to learn and use thanks to an intuitive user interface. The navigation tab groups the software’s functions—from observation to reporting—using large, clearly labeled buttons. Users can access a reduced user interface for a simple workflow, while experienced users can easily access advanced features. To streamline the workflow further, you can even customize the home screen with the functions used most often.

An organized interface with clearly labeled sections for the entire metallurgical image analysis process

2. Acquires large images fast.

It can be challenging to get a fully focused image of entire rough surfaces, such as fractured samples, multi-planar materials, and uneven polished samples, in metallography. With PRECiV software, acquisition of all-in-focus images that extend beyond the microscope’s field of view is made easy thanks to the extended focal imaging (EFI) and panorama functions:

- EFI: serially acquires multiple images in different focal planes to create an all-in-focus image

- Panorama: enables you to move the stage across the sample and then stitch the recorded images together into one large image

These two functions can be combined without disruption in the acquisition process to help shorten your inspection time.

3. Supports flexible imaging methods.

Brightfield is a commonly used method in metallurgical image analysis but may not show certain features of metals or alloys. Other imaging methods can be used to enhance different features:

- Darkfield can highlight the light scattering sections of a sample. For instance, grain boundaries in samples prepared with boundary etching that appear dark in brightfield are highlighted in darkfield images. Like brightfield, darkfield is commonly used in metallography.

- Differential interference contrast (DIC) enhances the local variation of image contrast related to surface defects (e.g., scratches, streaks, impurities).

- Directional darkfield is especially beneficial for the analysis of nonmetallic inclusions.

- Polarized light can show the individual grain orientation after grain surface etching. This imaging method combined with color etching is commonly used for aluminum microstructure analysis.

With PRECiV software, users can choose from a range of imaging methods, including brightfield, darkfield, MIX (directional darkfield), polarization, and DIC. As a result, you can easily find the ideal conditions to analyze materials and metals. Robust color rendering and high-resolution capabilities provide clear and sharp images.

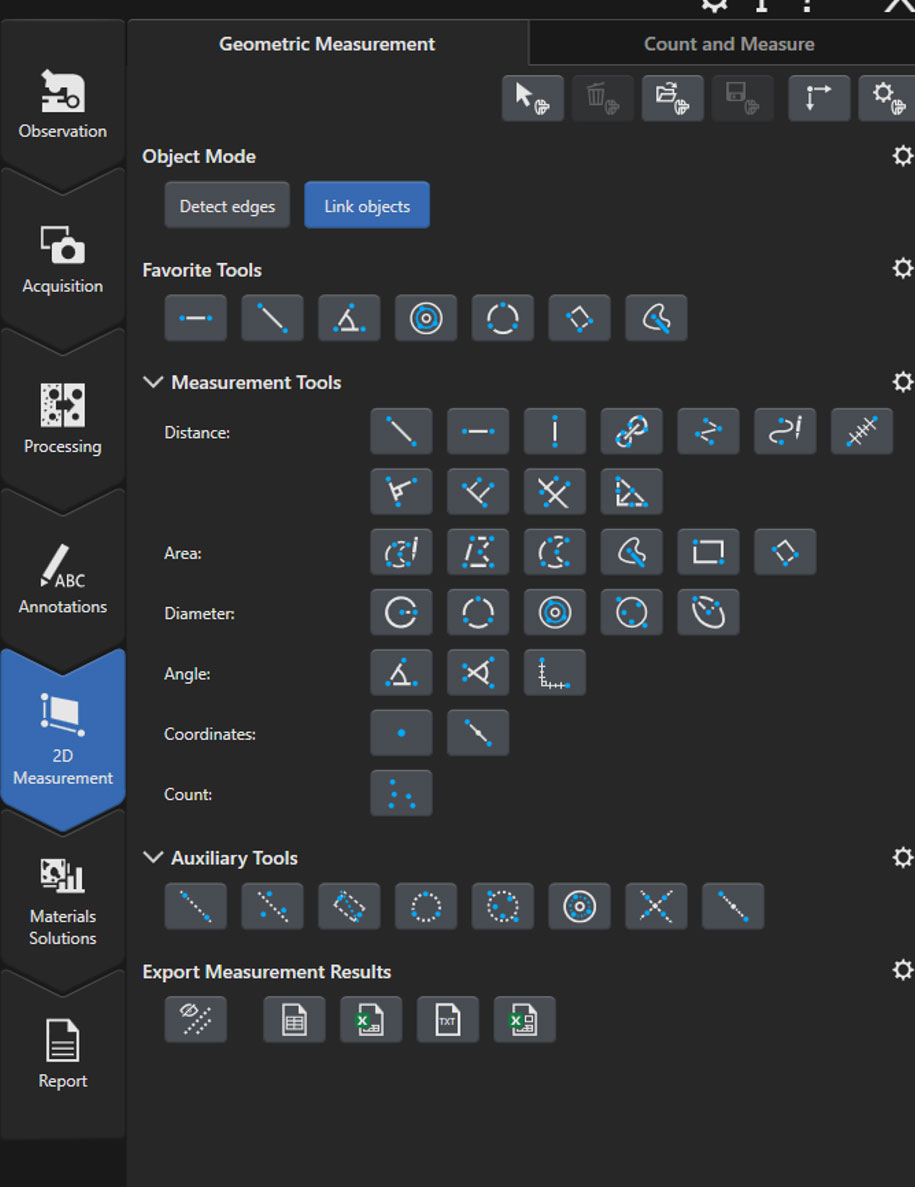

4. Enables precise two-dimensional measurements.

The software enables accurate, repetitive two-dimensional (2D) measurements on a live or recorded image. Powerful measurement functions include:

- Auto edge detection* to reliably measure the distance between two points

- Auxiliary lines* to easily make complex geometric measurements

- Magic wand for automatic area detection

*Available in PRECiV Pro and PRECiV Desktop.

The wide range of 2D measurement tools in PRECiV image analysis software

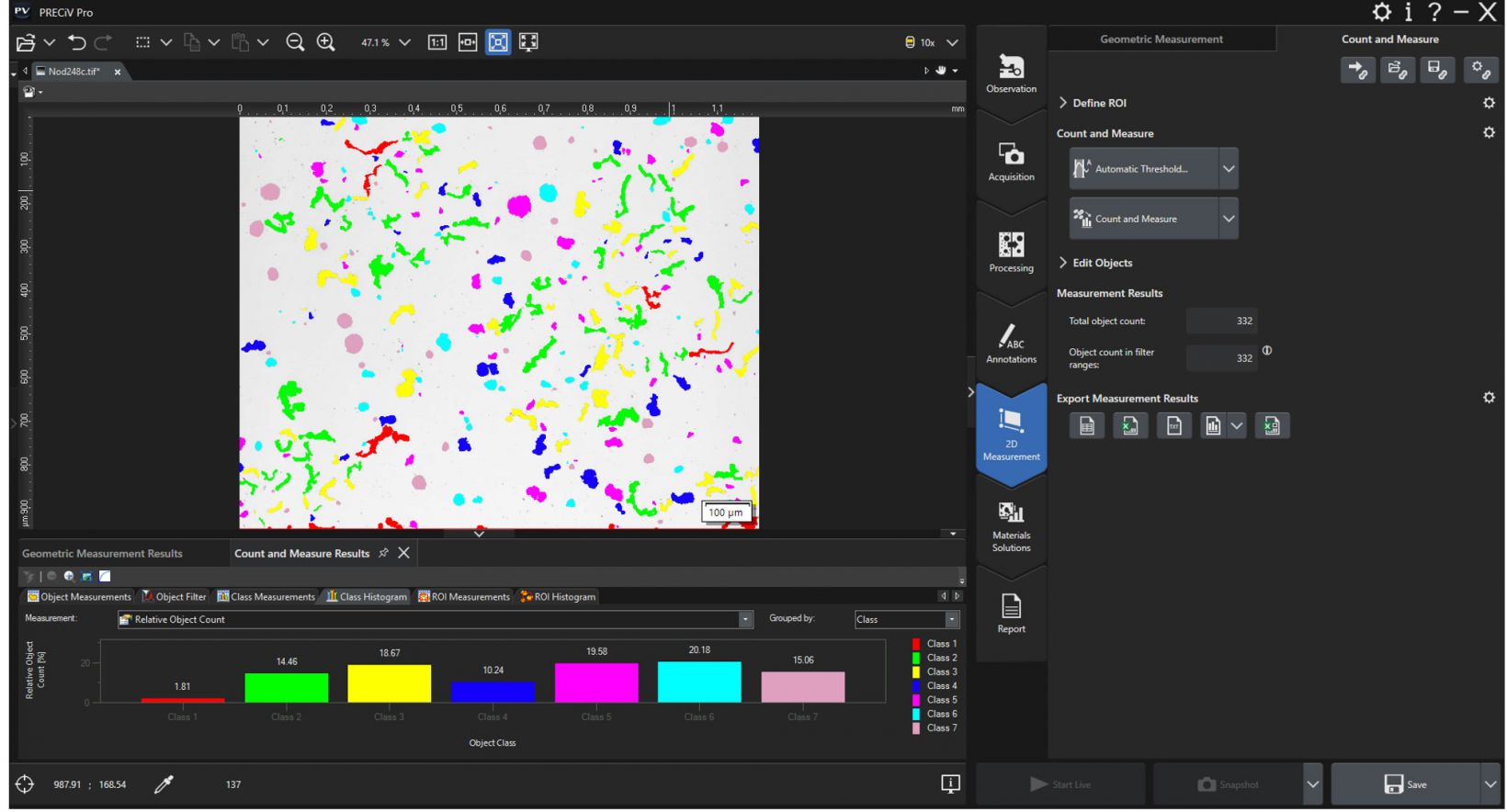

5. Offers advanced image analysis tools.

Metal powder industries such as powder metallurgy and additive manufacturing require a reliable solution to measure particle characteristics (e.g., particle size distribution and particle roughness) and morphological parameters (e.g., roundness or Feret ratio). This analysis helps ensure consistent quality.

The optional Count and Measure solution in PRECiV software lets you perform threshold-based particle analysis and phase measurement. You can select from a wide range of particle parameters and user-defined classifications that best represent the behavior of the sample under analysis.

The threshold-based phase analysis can be applied to metals, composites, and other materials that can be separated by the thresholding method.

The optional Count and Measure solution

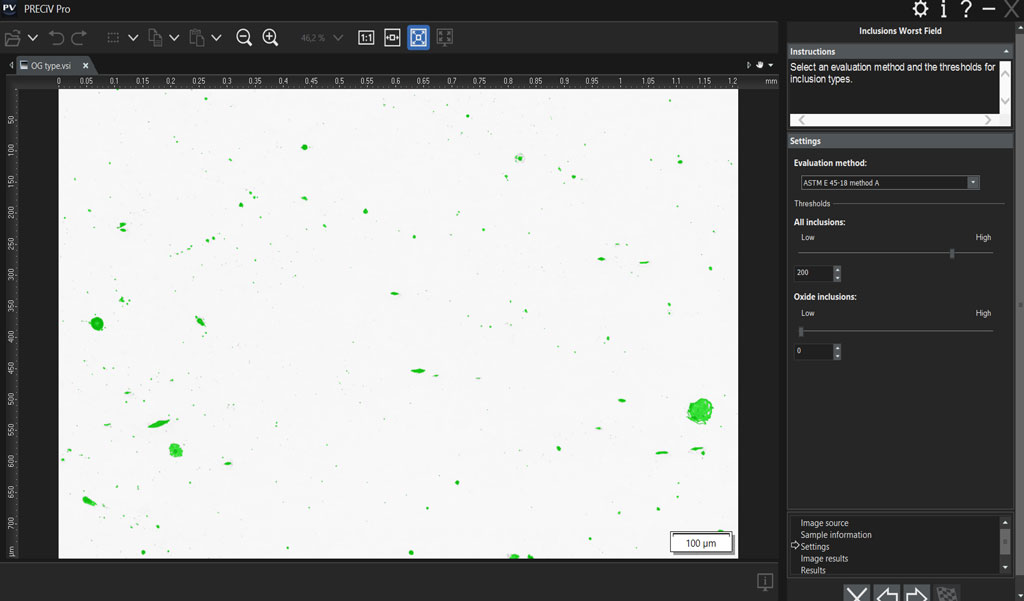

6. Greater confidence in your inspection results.

All measurements are calibrated so that you can have confidence in your inspection results. The software connects to the microscope and automatically calibrates the image magnification using a certified micrometer scale.

The system also provides compliant results for a range of international and national standards. For advanced applications like grain sizing or nonmetallic inclusions in steel, you can use the optional Material Solutions. These solutions guide you through the steps needed to acquire measurements that comply with the International Organization for Standardization (ISO), ASTM International, and Japanese Industrial Standards (JIS).

Inclusion content in steel for ASTM E 45-18 method A

These compliant results can be published in professional, analytical reports created in Word, Excel, or PowerPoint. You can freely modify the report template, such as your company logo or sample information, as needed.

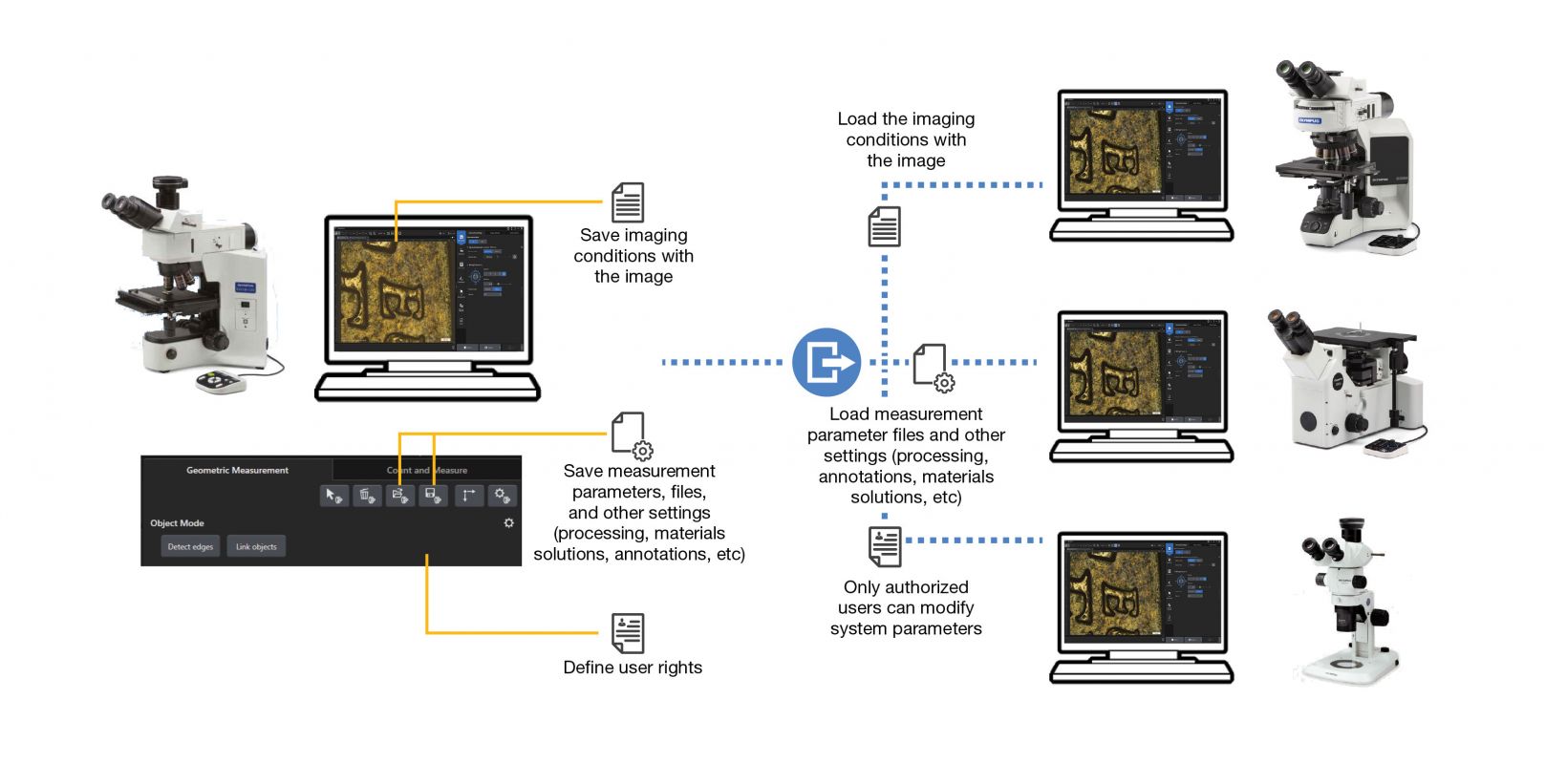

7. Connected workstations enable efficiency.

Robust data sharing and security features enable you to get the right information in front of the right person quickly. Easily export images, data, or professional reports and share the files across your company’s network.

Imaging conditions, measurement parameters, image processing settings, material solutions settings, annotations, and other relevant information can be stored in an image and recalled on any PRECiV workstation in your lab. Users with permissions to access the file can load the information on their workstation and get to work.

An example of secure image sharing across a company network using PRECiV software

Images can be saved and loaded in multiple formats for flexibility, or as a JPEG with the accompanying calibration information for traceability.

To learn more about PRECiV image analysis software, watch the video below or reach out to us for a demonstration.

Related Content

PRECiV Brochure: Take Control of Your Microscope

Video: Introducing PRECiV Image Analysis Software

Video: Panorama and EFI in PRECiV Software

Get In Touch

.jpg?rev=A930)