Borescope inspections in nuclear power plants can play a crucial role in helping ensure the safety, reliability, and regulatory compliance of the plant’s operations. They contribute to preventive maintenance efforts, assist in root cause analysis, and help maintain a high level of operational efficiency. For personnel performing these inspections, time and distance are critical measurements for achieving a safe working environment and avoiding harmful radiation exposure levels.

What Are the Radiation Dose Guidelines for Nuclear Plants?

Minimizing radiation exposure for inspectors in nuclear plants is crucial for protecting their health, ensuring compliance with regulations, and facilitating safe and effective inspections and maintenance activities. When these critical inspections reveal suspected corrosion or blocked conduits or vessels in the containment area, they must be handled immediately to help avoid accidental radiation leakage. In some cases, the reactor may need to be shut down so that workers outfitted in full-body

protective gear can carry out the inspection. However, remote visual inspection (RVI) offers an alternative to this method, helping avoid costly shutdowns, saving time and operational costs, and reducing the risk of a harmful radiation dose for workers.

NRC Standards

The Nuclear Regulatory Commission (NRC), a key regulatory body, imposes stringent guidelines to monitor and regulate nuclear facilities. They ensure compliance with safety protocols to minimize potential risks associated with nuclear materials and radiation. Workplace radiation exposure is meticulously regulated in accordance with these safety standards, and the annual effective dose limit is established at 5 rems (0.05 sieverts (Sv)). To provide context, the average person typically encounters

less than 0.003 sieverts of naturally occurring radiation annually. Workers in nuclear plants generally experience exposure levels of less than 0.01 Sv per year, a threshold deemed reasonably safe by prevailing standards. Adhering to these guidelines ensures a controlled and secure environment for individuals operating in nuclear facilities.

Definition of “As Low As Reasonably Achievable” (ALARA)

The ALARA (as low as reasonably achievable) principle is a fundamental approach in radiation safety, emphasizing the need to minimize radiation exposure to the lowest achievable levels, without compromising the efficiency of plant operations. This principle requires continuous vigilance, employing advanced technologies, and optimizing work procedures to keep radiation doses well below established limits. Remote visual inspection technology has continued to evolve and provide a safer

alternative for personnel to make their inspections from a sufficient distance to help decrease their annual effective dose level.

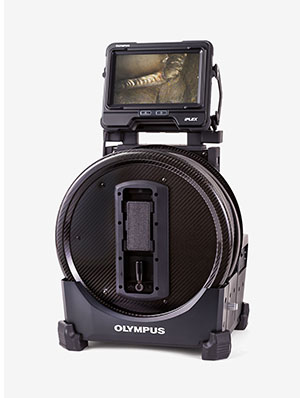

Important Requirements for a Video Borescope Used in Nuclear Power Plants

| Industrial video borescopes are advanced inspection tools that enable inspectors to perform visual observations remotely via external camera-based equipment. The video borescope’s insertion tubes are used to access the target area, while video technology enables an inspector to analyze the area from a distance through a monitor. Image data can be viewed in real time on the screen and recorded for further assessment, analysis, and reporting IPLEX™ video borescope systems offer inspectors the ability to quickly identify issues, facilitating faster decision-making and targeted maintenance. Our industrial borescope technology delivers durable and maneuverable insertion tubes that can easily navigate complex structures within the plant. We offer IPLEX models with different configuration options and multiple insertion tube diameters and lengths to adapt to varying and challenging inspection conditions. Additionally, the captured video and images serve as valuable documentation for reporting, supporting thorough inspections that comply with regulations. |

Time and distance are important factors for determining inspection conditions. Video borescopes equipped with a long insertion tube can enable the visual inspection of difficult-to-access locations, such as water conduits. The longer the insertion tube, the farther away the workers can be from the radiation. The reactor vessel contains components crucial to the plant’s operation, but accessing these areas can be challenging due to high radiation levels. Video borescopes are deployed to

visually inspect the reactor vessel internals, including the core shroud, control rod drive mechanisms, and other critical elements. Inspectors can navigate the borescope remotely, capturing real-time video and images to assess the condition of these components without direct human entry into the high-radiation environment.

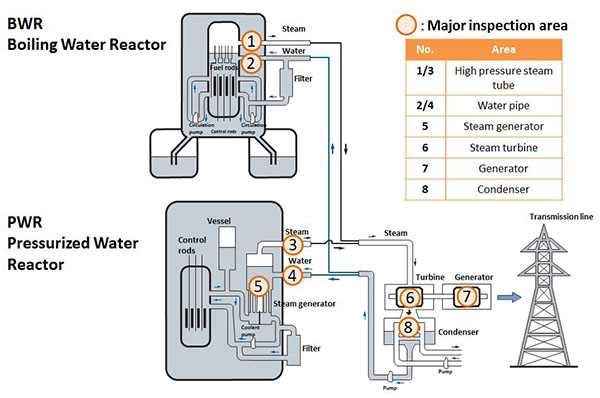

Illustration of the areas to inspect inside a pressurized water reactor (PWR) and a boiling water reactor (BWR)

Unfortunately, even the best video borescope equipment doesn’t come out completely unscathed when exposed to radiation. If the insertion tube is used to inspect dirty-water-filled pipes, contamination is inevitable, and damage is also a possibility. When the equipment is used in high-radiation areas, in some instances, decontaminating the equipment may be considered too costly and risky for the health of the workers. The plant may opt to sacrifice the insertion tube, leaving it permanently in the radiation area. Regardless, the insertion tube and the videoscope need to be robust enough to satisfy the requirements and expectations of the nuclear plant’s safety inspection and maintenance programs. That’s why we build systems, such as the IPLEX GAir video borescope, with features that enable them to survive longer in radiation areas.

The following is a list of 5 ways that the GAir system is optimized for inspection in nuclear power plants.

5 Advantages of the IPLEX™ GAir Video Borescope in Nuclear Power Plants

1. Resistant to radiation damage

We tested the IPLEX GAir video borescope’s insertion tube and found that, even after being exposed to 1,400 Gy (a unit that measures an absorbed radiation dose) cumulatively, the laser illumination and CCD image sensor still work. Particularly beneficial is the LED illuminated optical tip adapter, which eliminates the necessity of using optical fibers that can yellow when exposed to radiation. This results in a longer lifetime in a radioactive environment. Depending on the type of radiation, 1 Gy is roughly equal to 1 sievert. That means that the insertion tube can withstand many times more radiation than the established safe limits for workers: around 140,000 times a person’s annual exposure limit.

2. Inspect from a safer distanceThe IPLEX GAir video borescope has an extra-long insertion tube that enables workers to make inspections from a safer distance. The 30-meter (100-foot) tube can be fed into dirty water pipes in the radiation containment area, and workers can control and maneuver it from afar. For greater flexibility, a USB wireless LAN adapter enables you to observe live images and record still images and movies on a tablet PC from 15 m to 20 m (49 ft to 65 ft) away from the unit. With a commercially available repeater system, the IPLEX GAir video borescope can be remotely controlled from up to 100 m (328 ft) away. |  |

3. Replaceable insertion tube

The IPLEX GAir videoscope's interchangeable insertion tube can be replaced at the inspection site. This saves time and reduces cost since the inspector can bring a spare scope and change it in the field if the original becomes contaminated with radiation.

4. Optimal illumination, contrast, and exposure

Image brightness is essential to inspect the inside of a pipe or vessel from far away. The IPLEX GAir video borescope's optical tip adapter features LED illumination that continuously delivers bright light regardless of the scope length. Combined with WiDER™ (wide, dynamic extended range) image processing, the videoscope delivers bright, contrast-balanced images across the entire depth of field. In addition, the long exposure function help users find defects easily when inspecting large spaces, such as a reactor vessel.

5. Easy handling for quick inspection

To maximize an inspector's safety, inspections in a radiation environment must be completed as quickly as possible. The IPLEX GAir video borescope's pneumatic articulation is compact with an integrated air compressor, enabling you to quickly carry the system to an inspection site.

When you’re maneuvering the insertion tube through a pipe, a gravity sensor in the scope tip automatically orients the image so that you know which direction is up, reducing any confusion and speeding up the inspection. In addition, a guide head on the scope’s distal end makes it easier to pass smoothly through pipe elbows, further enhancing your inspection efficiency.

Explore Our Video Borescope Solutions for Nuclear Plant Equipment

Discover our full range of IPLEX video borescope solutions for nuclear power plant inspections including turbines, steam generators, reactors vessels, condensers, and pipes, in primary systems (nuclear islands) and secondary systems (conventional islands). Don’t hesitate to contact us to discuss which video

borescope is best for your needs.

Related Content

Tips to Ease Your Code-Compliant Visual Inspection Imaging Recording and Reporting

Demonstration of Essential Videoscope Features for Remote Visual Inspection (RVI)

Extra-Long Videoscope Withstands Tough Inspection Environments