Your Safety Is Riding on It

When passengers board a train, most don’t consider the amount of work that goes into inspecting key components to help ensure a safe ride. An essential tool in this inspection process is a phased array flaw detector that sends high-frequency sound waves from a probe into a component to look for defects. If the sound waves encounter a flaw, some of the sound energy gets reflected back to the probe. The flaw detector reads these signals and displays information that a trained inspector can use to assess the condition of the part.

From high-speed passenger trains to cargo-laden freight trains, the wheels, axles, and rails that support all railway traffic sustain an immense amount of stress. Heavy loads, speed, and friction combine to generate contact fatigue and damage in train wheelsets and rails. To avoid catastrophic failures that could lead to a crash or derailment, strict standards regulate the manufacturing and maintenance of rail parts.

Rail industry inspection standards are specific to the regulating body of the region where the manufacturing or maintenance takes place. The precision and detection demands vary from code to code. However, one aspect of code compliance seems to be consistent

Our phased array train inspection systems reflect this philosophy.

Ensuring Wheels, Axles, and Rails Surpass the Highest Safety Standards

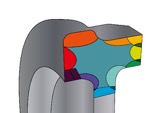

The detection performance of our phased array systems for train inspection applications is designed to exceed the current requirements of the strictest international inspection codes. For example, according to certain codes, reprofile shops (where worn train wheels are machined so that they can be reused) and maintenance depots inspecting the wheels of high-speed bullet trains must be able to detect flaws (flat-bottom holes) as small as 2 mm (0.08 in.) at various depths beneath the tread surface. The sensitivity of the FOCUX PX™ phased array ultrasonic testing (PAUT) system surpasses this requirement. Not only that, its 2D array capability helps eliminate surface echoes, so the probability of detection for near-surface defects is higher. This is a vast improvement over conventional ultrasonic and 1D array systems.

|  |  |

Train wheel manufacturing and in-service inspection with the FOCUS PX phased array system

Solutions Tailored for Varying Train Inspection Needs

Since detection and precision requirements range from freight trains to high-speed bullet trains and change from region to region, train inspection solutions must adapt to customers’ current and future needs.

- Scalability: Up to four FOCUX PX phased array units can be used in parallel to drive the number of arrays required to ensure all the desired areas of a wheel or axle are inspected with high precision. A system using our QuickScan™ LT phased array technology, is also scalable. The number of phased array probes and QuickScan LT units depends on the number of zones and the level of sensitivity required by the manufacturer.

- Easy upgrading: As the rail industry changes and evolves, the FOCUS PX system can be adapted and expanded to meet the new demands. Currently, multizone coverage of train wheels is only required by some codes in certain countries, but not others. The FOCUX PX system is already capable of multizone coverage. If users desire it, they can add arrays to their system to inspect more zones.

Multizone coverage of a train wheel with phased array

The system can be configured to cover standard inspected zones of rails but can inspect additional zones if required.

- Customizable: The companion software for the FOCUS PX system, FocusPC, has a customizable user interface, and available software development kits (SDKs) enable you to tailor your system to specific inspection applications.

Code-Compliance without Compromise

The FOCUS PX automated train wheel and axle inspection system is capable of reliable, code-compliant defect detection without sacrificing productivity. The number and configuration of the systems’ acquisition units can be optimized so that they meet the speed requirements while maintaining the desired detection performance.

The customizable, easily upgradable FOCUS PX system provides rail industry manufacturers and service facilities with the tools they need to reliably validate the integrity and security of train wheels, axles, and rails. Stringent, high-quality inspections help ensure railway passengers arrive safely at their destination.

Related Content

Video: Automated Train Wheel Inspection Systems

How Nondestructive Testing Helps Keep Railways on Track

Automated Train Wheel Inspection

Get In Touch