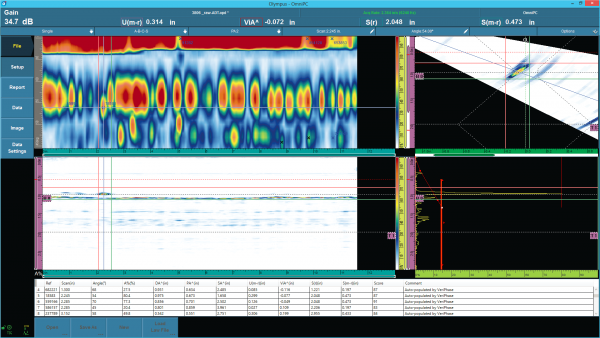

Inspectors know that phased array offers powerful imaging capabilities to locate flaws and defects, but it also generates a tremendous amount of data. And as the technology continues to evolve, the size of data files is only getting larger. Analyzing phased array data has always been one of the biggest challenges when it comes to finishing a customer’s contract. Committing to a tight schedule without knowing the potential delays and what you’ll find in the inspected component are some of the biggest gambles inspection companies deal with every day. Fortunately, Automated Detection Technology™ (ADT) software from VeriPhase® works with our OmniScan® series flaw detectors to help you target your analysis, so you can get the job done quickly and efficiently.

How does it work?

ADT software processes OmniScan data files as they’re acquired. The software creates a new copy of your data file with an

For every indication that’s detected, the ADT software provides a confidence level rating. Every possible indication detected by the software is flagged, so you can spend your time focusing on the areas of interest.

In addition to helping you save time by providing a prepopulated indication table, ADT software also assesses the quality of your data, including checks for loss of couplant and loss of data, and helps ensure that your data is code compliant. If a user makes a mistake during the inspection setup, the software can help reduce potential human error.

What information does the software provide?

ADT software uses the raw data files. This means that it doesn’t matter where you put your gates—the software looks at all the data collected by the flaw detector to populate the indication table. The software automatically places cursors for every indication that it detects and

Get In Touch