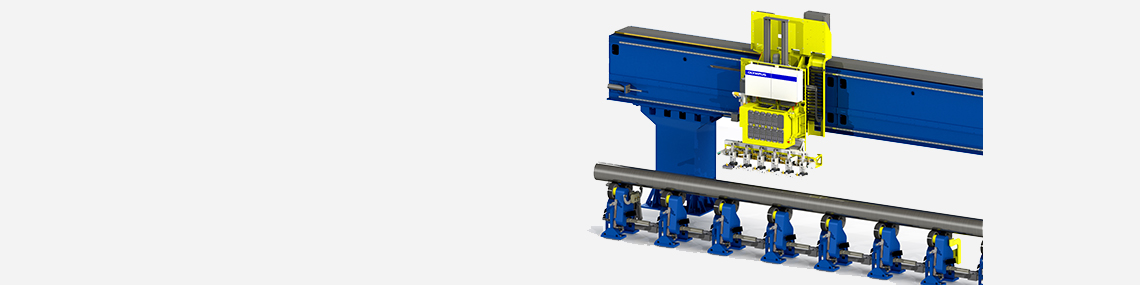

Rotating Tube Inspection System (RTIS)

Overview

The rotating tube inspection system (RTIS) is a turnkey solution that uses phased array probes integrated into a fully automated testing system to meet stringent requirements for volume and surface inspections. Key benefits include:

Full Body Tube Inspection

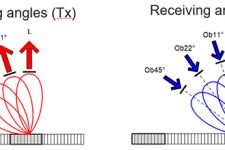

Inspect for longitudinal, transverse, oblique, and lamination defects, and measure wall thickness.

- Novel water wedge enables many degrees of freedom to accommodate pipe movement and provide excellent coupling

- Design leaves only small untested tube ends

- Automatic calibration for repeatable results

- High sensitivity on small reference defects with a signal-to-noise ratio greater than 12 dB

- Can be used to fulfill testing regulations (API-5CT and API-5L)

Longitudinal |  Transverse |  Oblique |

Maximize Your Productivity

The system is adaptable and can be configured to suit different types of inspections.

- The number of inspection heads or electronics can be adapted to meet the required productivity level

- Up to four apertures per phased array probe can be fired simultaneously

- Large mechanical scan overlap covering up to 120 mm/r

Automatic CalibrationTo achieve a thorough inspection, each phased array probe must be calibrated. During calibration, the apertures of each probe pass over a known defect, and the probe’s gain level is automatically adjusted. This feature enables users to easily perform and validate a precise calibration of each focal law, saving time without relying on the user’s skill.

|  |

Software and Acquisition Unit

The combination of phased array probes, a powerful acquisition unit, and advanced software work together to deliver a powerful, easy-to-use inspection system.

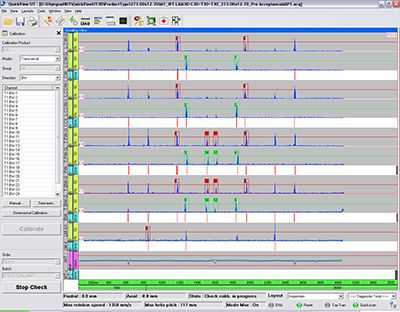

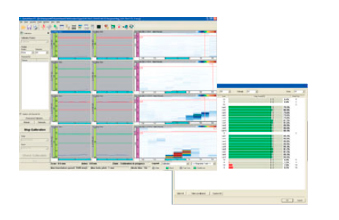

Phased Array Acquisition UnitThe QuickScan™ PA 32:256 module meets IP55 standards and is designed to easily integrate into industrial environments. Easy SetupQuickView software makes it easy to setup the system and acquire and manage data. The software’s wizard makes it simple to create setups for each part size. The inspection configuration and calibration parameters for each pipe diameter are saved and easily retrievable. The final results are merged and displayed to clearly differentiate between accepted and rejected tubes. |  |

- Quickly access predefined inspection setups

- Software wizard makes it simple to create new setups

- Restrict access to certain users to help minimize operator errors

- Calibration and inspection info are stored for traceability

- Acquisition files are created for every inspected tube, and these data can be stored locally or remotely

- Custom reporting and advanced process control tools

Clear Results

Specifications

| Standard Product Range > Diameter | 60 mm to 508 mm (2 3/8 in. to 20 in.) |

|---|---|

| Standard Product Range > Wall Thickness | 4 mm to 75 mm (0.157 in. to 2.95 in.) |

| Standard Product Range > WT/OD | < 0.3 |

| Standard Product Range > Length | 6 m to 15 m (20 ft. to 50 ft.) |

| Standard Product Range > Speed |

60.3 mm (2 3/8 in.) : 1 m/s (200 ft./min)

244.4 mm (9 5/8 in.) : 0.25 m/s (50 ft./min) 406.4 mm (16 in.) : 0.15 m/s (30 ft./min) |

| Inspection Coverage > Axial Pulse Density (APD) | Configurable (0 to > 50% overlap) |

| Inspection Coverage > Radial Pulse Density (RPD) | Configurable (1.0 mm to 2.0 mm) |

| Data Presentation > Real-Time Inspection Results | C-scan, strip charts, and alarms |

| Data Presentation > Parameter Setup | A-scan, B-scan |

| Data Presentation > Inspection Layout | 20 different user-configurable layouts |

| Inspection Modes > Typical Inspection Modes | Longitudinal, transverse, oblique, lamination, and wall thickness measurement |

| Inspection Modes > Firing Modes | Pulse-echo |

| Inspection Modes > Inspection Mode Configuration | Several inspection modes can be performed simultaneously on the same PA probe. |

| Detection Capabilities for Typical Reference Defects > API References |

12.7 mm/25.4 mm N10 and N5, ID and OD longitudinal, traverse, and oblique notches;

3.2 mm and 1.6 mm through-drilled hole (TDH), 6.35 mm flat bottom hole (FBH) |

| Detection Capabilities for Typical Reference Defects > Signal-to-Noise Ratio (SNR) | > 12 dB |

| Detection Capabilities for Typical Reference Defects > Repeatability |

L notches: < 2 dB

T and Ob notches: < 3 dB TDH 3.2 mm and FBH 6.35 mm: < 4 dB |

| Reporting and Data Storage > Report types | Inspection, calibration, and calibration-check user-configurable reports |

| Reporting and Data Storage > Storage | Real-time database inspection data storage |