Heavy Forging Solutions

Overview

Heavy Forging Inspection

Forging is a process used to manufacture metal components requiring high strength, such as turbine generator shafts and large disks. In this process, metals are most commonly heated and shaped using compressive forces. Forging has the advantage of producing stronger parts than casting or machining.

The forging process is associated with the emergence of natural volumetric defects such as inclusions and porosities. These defects can be located anywhere in the part volume and must be reliably identified and characterized in order to ensure high quality parts.

Natural DefectsInclusions and voids can be located anywhere in the metal volume, from the subsurface region to the core. These defects must be correctly located and sized regardless of their location inside the part. |  |

|

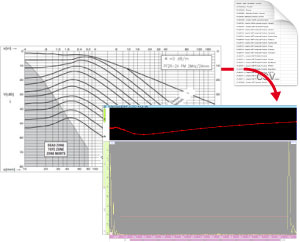

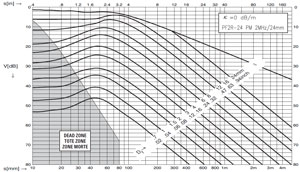

Illustration of beam propagation and corresponding DGS curve diagram. Calibration ReferenceForged part inspection systems are usually calibrated using back wall reflection. A distance gain size (DGS) curve is generated based on the expected equivalent reflector size (ERS). This DGS curve can be converted to a time-corrected gain (TCG) curve to simplify defect identification and improve operator efficiency. |

Inspection Technique

Volumetric Inspection Volumetric inspection is performed using a phased array probe that generates longitudinal waves at various angles. Conventional ultrasonic (UT) probes are added to generate high-angle shear waves. | Subsurface Inspection Subsurface inspection is conducted using a pitch-catch conventional UT probe, which minimizes the near-surface dead zone. |

|  |

Solution

High-performance Solution

Quality PA and UT InstrumentThe FOCUS PX uses the latest Olympus phased array technology to generate unprecedented signal-to-noise ratio (SNR). Four additional dedicated conventional UT channels are available for added flexibility in heavy forging inspection configurations.

|  | ||

Application-dedicated Phased Array Probe and WedgeThe dedicated Olympus heavy forging phased array probe offers improved SNR compared to competing products and also allows multiple angle coverage capability. A custom fit near-contact wedge is available to optimize coupling.

|

2 MHz phased array probe designed for optimized SNR. |

Powerful Software

FocusPC software contains advanced features designed to optimize heavy forging inspection applications, taking full advantage of the high-end FOCUS PX specifications.

Continuous Inspection Data files are continuously generated throughout the inspection process, allowing uninterrupted inspection of very large specimens. | Custom TCG Inspection Import DGS-based TCG curves to simplify defect identification and improve operator efficiency. |

FocusPC continuous inspection feature |

FocusPC TCG import feature |