Radiator fin for vehicles

Manufacturing Radiators for Vehicles

A cooling system is installed near a vehicle’s engine to keep it cool. It generally cools the engine with liquid coolant. The engine heats up the coolant, which travels through the many pipes making up the radiator where the heat is dissipated into the air. The coolant then returns to the engine, and the process repeats. The pipes in the radiator connect to fins that form a heat sink and increase cooling efficiency.

Radiators are usually made of an aluminum alloy since they have a high cooling effect. Their components are thin to expand the cooling area. The radiator pipes and fins are joined by brazing, a method of joining metal components using a melted filler metal.

There are many metal types used as the brazing filler metal, but they need to have a lower melting point than the base material to ensure that the components are not damaged during the brazing process. The filler metal joins components by flowing into the joint between the two components using the capillary effect. Brazed joints are strong and corrosion resistant, and brazing enables multiple points to be joined at once. Brazing is an effective joining method for radiator fins when multiple points need to be joined.

The Importance of Inspecting Brazed Joints

For quality control, it is important to confirm that components are brazed correctly to prevent them coming loose. If the fin separates from the joint with the pipes, it can pierce the pipes and cause a leak, which can lead to the engine overheating.

For this reason, inspectors check the brazed joint’s condition using microscopes. However, there are various microscope observation methods available, and inexperienced inspectors may have difficulty choosing an appropriate one.

Advantages of Inspecting Brazed Joints of Radiator Fins Using the DSX1000 Digital Microscope

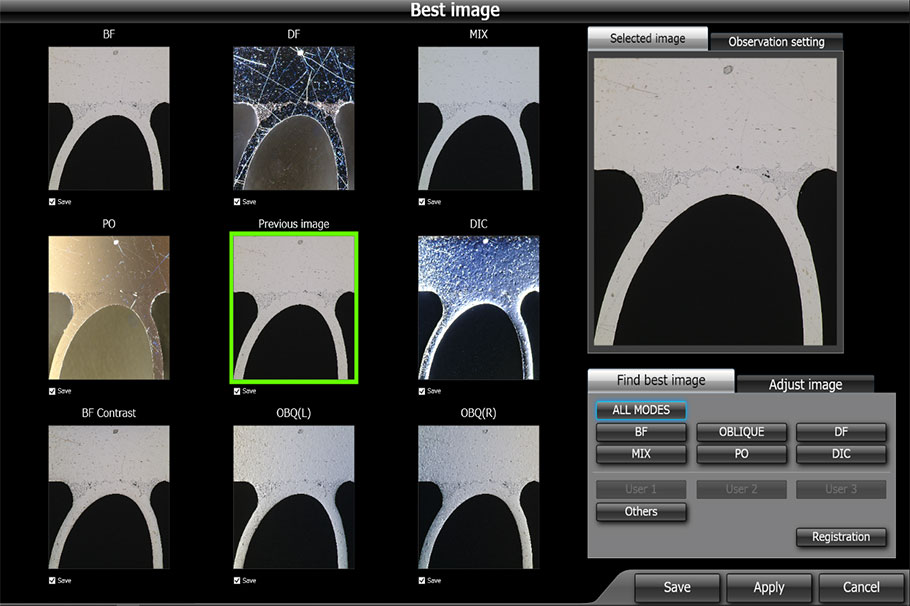

1) Easily select the appropriate observation method with the multi-preview function

The DSX1000 microscope’s multi-preview function makes it simple to view the sample using multiple observation methods to find the right one. The microscope automatically optimizes the field stop and illumination adjustment for each observation method. This feature also helps ensure that the observations are carried out in a repeatable way regardless of operator.

| |

| |

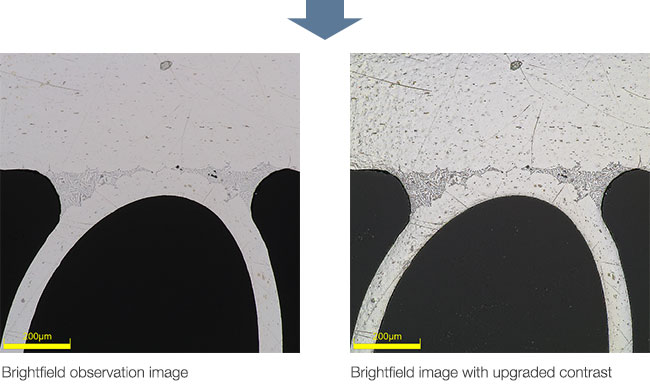

The brazed joint condition is more clearly visible in the brightfield image with upgraded contrast than in the brightfield image. | |

2) See the details with a wide range of magnifications.

After identifying the point you want to inspect, you can quickly change the magnification using the easy-to-use optical zoom dial.

The optical zoom of up to 10X is controlled by turning the jog dial on the console box.

|

Sometimes finding the proper magnification requires you to change the objective lens. The DSX1000 microscope makes this process simple; you can quickly change objectives by sliding them back and forth. Up to two lenses can be attached to the head at the same time.

|

If you have to remove the objectives and insert a new one, this is also easy. You can slide the old objective out and slide the new one into place in just a few seconds.

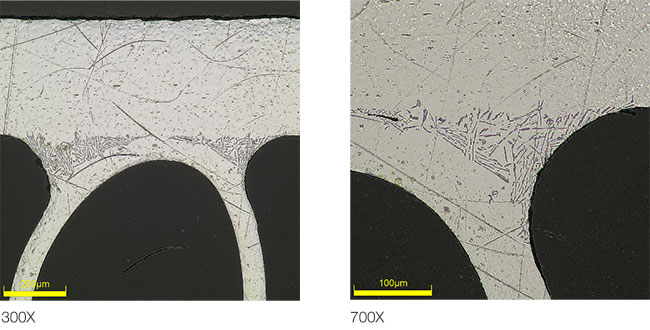

(Left: the radiator fin's brazed condition can be seen macroscopically. Right: the brazed condition of an individual area can be seen in more detail)

3) Instantly switch observation methods.

Easily switch observation methods by pressing a button on the console box to streamline your brazed joint inspection.

Image acquired using the differential interference contrast (DIC) observation method (700X). |