Application

A coated abrasive consists of abrasive grains, such as diamond fragments, bonded to the surface of synthetic fabric, craft paper, or non-woven cloth using synthetic resin. To precisely control the abrasive quality, the condition of the bonded abrasive grains needs to be carefully managed. Checking the condition of abrasives with a conventional laser microscope is difficult because the reflectivity of the areas with sharp abrasive grains is extremely low, while the reflectivity of flat areas is very high. Consequently, three-dimensional imaging of coated abrasives has been difficult for laser microscopes.

Olympus' solution

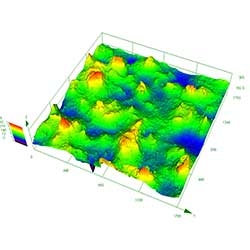

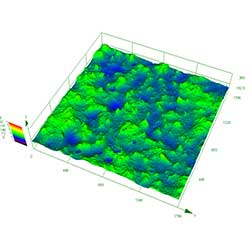

Olympus' LEXT 3D scanning laser microscope has dual confocal technology that enables users to evaluate the profile of abrasive surfaces that have heavy irregularities, observe the distribution of abrasive grains, and examine surface roughness quantitatively. With its dual confocal system, the LEXT can acquire a reliable 3D image even for surfaces made up of materials with different reflectivities so manufacturers can evaluate their abrasive materials. With the microscope’s stitching mode, users can combine multiple images to form a single wide-area observation in high resolution, making it easy to identify differences in roughness across a large surface.

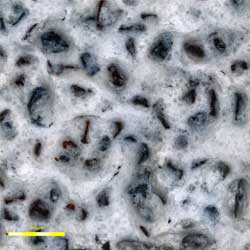

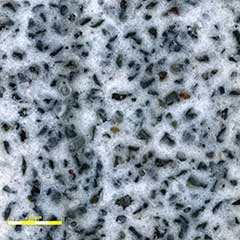

#100   20X objective lens; 1X zoom; 3×3 stitching | #240  20X objective lens; 1X zoom; 3×3 stitching |