This application note explains how to detect fatigue cracks in marine propellers using eddy current testing. Learn why these cracks form and the key advantages of using eddy current testing to detect them. |

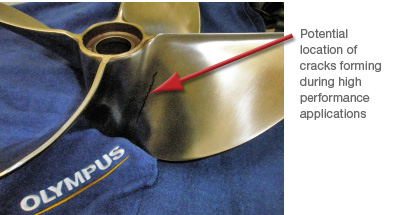

Causes of Cracks in Marine PropellersPropellers used on boats of all sizes and types undergo cyclic fatigue, which can cause cracks. These cracks can cause potentially serious consequences, including total loss of watercraft, loss of lives, or delay in time of arrival. As a result, propellers are inspected across the maritime industry. Propellers are made from various materials, including bronze, aluminum, stainless steel, and carbon steel. All these materials are susceptible to cyclic fatigue. |

|

Cracks can originate at many locations on propellers. In most cases, the crack begins at points of highest stress loads associated with stress risers, such as sharp edges, thick to thin transitions, and areas where weld repair occurred. The most common point of failure on propellers is where the blade joins to the hub. Cracks occur anywhere along the axis of the blade to the hub radius.

Advantages of Eddy Current Testing for Fatigue Crack Detection in PropellersEddy current testing brings many benefits to propeller inspections, including: |

|

|

The applicable NDT techniques for the propeller inspection depend on the construction material, type of defect, and location of the component being inspected. Magnetic particle inspection, dye penetrant, and visual inspection may also be used where applicable.

Typical Equipment Used for Fatigue Crack Detection in Marine Propellers |

| NORTEC™ 600 eddy current flaw detector Pencil probe: 100–500 kHz, part number 9222164 Right angle weld probe: 100–600 kHz, part number WCD90I-5-50 |

Eddy Current Testing Procedure to Detect Cracks in Propellers

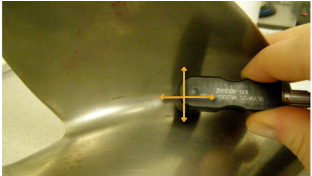

We performed an example inspection to demonstrate a typical eddy current testing procedure for fatigue crack detection in marine propellers. To achieve optimal results, two scans using two different eddy current probes were used to complete the inspection. The first scan used a conventional pencil probe, which is commonly used to detect surface cracking. The second scan was performed using a NORTEC weld probe, chosen due to its contoured face. |

Example of scanning a propeller with eddy current testing |

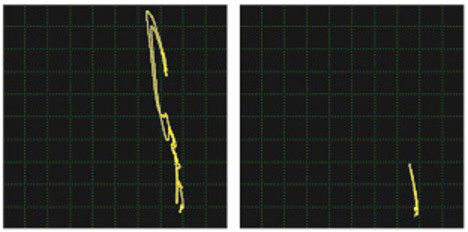

Comparison of a crack signal to a defect-free area using a weld probe |

Fingertip probe can be used as well |