Software Options

The 45MG offers five code-activated software options that makes it one of the most versatile thickness gages in the industry.

Echo-to-Echo / THRU-COAT® Option

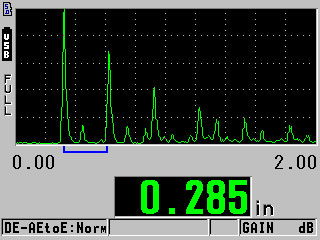

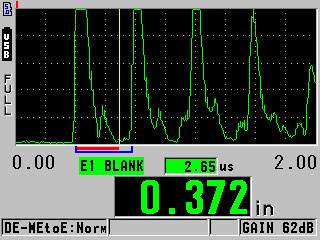

Echo-to-Echo The gauge displays the true metal thickness and ignores the thickness of the coating layer, using multiple back-wall echoes:

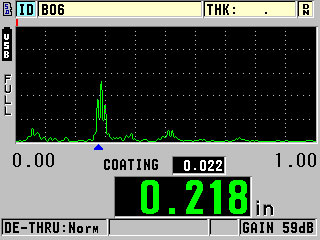

| THRU-COAT Technology

|

Auto Echo-to-Echo mode with A-scan |  THRU-COAT mode showing thickness of coating and steel (waveform not activated) |

Manual Echo-to-Echo adjusting the First Echo blank |  THRU-COAT mode with optional waveform |

Single Element Software Option

The Single Element software option enables you to make very precise thickness measurements at a resolution of up to 0.0001 in. or 0.001 mm. Compatible with single element Microscan transducers ranging from 2.25 MHz to 30 MHz.

- Most materials, from thin to thick

- Plastic bottles, tubes, pipes, sheets as thin as 0.08 mm (0.003 in.)

- Metal containers, steel coils, machined parts as thin as 0.10 mm (0.004 in.)

- Cylinder bores, turbine blades

- Glass bulbs, bottles

- Thin fiberglass, rubber, ceramics, and composite materials

- Curved areas or containers with small radii

Single Element High Penetration Software Option

This option allows you to use low frequency single element transducers (as low as 0.5 MHz) to measure thick or highly attenuating materials such as rubber, fiberglass, castings, and composites. Included is the Single Element option.

- Most thick or sound-attenuating materials

- Thick cast metal parts

- Thick rubber tires, belts

- Fiberglass boat hulls, storage tanks

- Composite panels

- Resolution of 0.01 mm (0.001 in.) for transducer frequencies of 0.5 MHz and 1.0 MHz

Optional Data Logger and PC Interface

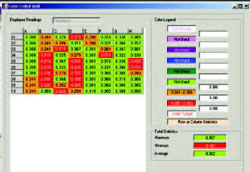

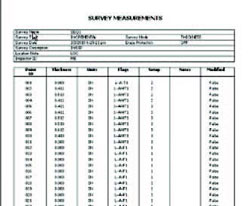

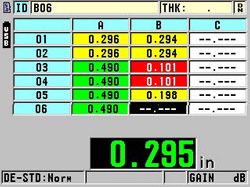

The 45MG has a full-featured internal bidirectional alphanumeric data logger that is designed to easily store and transfer thickness readings and waveform data. The data logger option includes the GageView™ Interface program. Data Logger Option

|

GageViewInterface Program

|

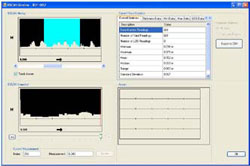

Live A-Scan With Waveform Adjust

This optional Live A-scan mode allows users to view the ultrasound waveform (or A-scan) directly on the gauge's display, verify the thickness measurement, and make manual adjustments to gain and blanking settings to maximize measurement performance in challenging applications. This helpful option features Manual Gain Adjust, Extended Blanking, First Echo Blank, Range, and Delay.