The use of corrosion-resistant material, such as austenitic alloys for weld, base material, or cladding, is getting more popular because of its durability. However, the corrosion-resistant material makes weld inspection difficult, and sometimes unachievable.

Challenges

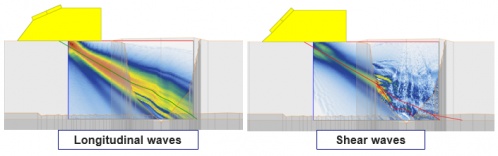

When using standard pulse-echo shear-wave techniques, austenitic alloys can cause beam skewing and beam scattering, resulting in a poor signal-to-noise ratio (SNR). As demonstrated below, the interface between carbon steel material and the dissimilar metal blocks the shear-wave signal and creates noise, making the weld inspection impossible!

|

| The shear-wave signal is blocked at the interface between steel and the austenitic material. |

Longitudinal waves (LW) are significantly less affected by the steel/austenitic interface than shear waves (SW) (as illustrated below). However, although the traditional LW pulse-echo technique works better in austenitic material, the technique still has drawbacks:

- The wedge requires a very tall design to eliminate the internal reflection problems associated with the pulse-echo technique. In some cases, more than 1/3 of the energy is attenuated in the wedge. To compensate for this attenuation, a higher gain has to be used, resulting in a worse signal-to-noise ratio.

- Using LW, the skipping technique used to inspect the upper part of the weld is impossible due to the many mode conversions. This leaves the entire upper portion of the weld not inspected.

- Since the skipping technique won't work, another technique has to be used to complete the weld coverage. Most commonly, inspectors use a transmit-receive-longitudinal (TRL) conventional UT probe that generates creeping waves with a very poor signal-to-noise ratio to inspect the upper portion of the weld.

|

| Comparison between LW and SW traveling through austenitic weld material. |

Solution

To meet the challenges of austenitic weld inspection, we developed a series of probes and wedges that use an ultrasound technique better suited to inspecting austenitic material. The dual matrix A17 and A27 probe series are used in tandem to generate transmit-receive-longitudinal waves (TRL), leading to a significant SNR improvement.

Acoustically insulating the transmitter and receiver probes eliminates the problematic wedge echoes associated with the pulse-echo technique without requiring a damping material or a taller wedge design. A smaller wedge generates less attenuation and enables the useful focus depth of the probe to extend further into the material.

|

| Wedge design comparison between dual matrix array probes (left) and pulse-echo LW probes (right). |

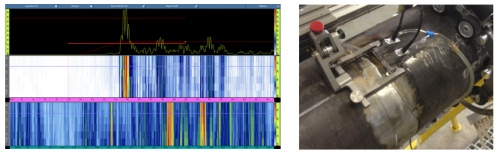

A combination of probe technology and wedge design enables detection and sizing of volumetric flaws as well as detection and positioning of surface connected flaws with excellent signal quality and a very low level of noise.

|

| Dual-sided stainless steel weld inspection with 4 MHz A27 DMA probes and an OmniScan® MX2 flaw detector. |

|

| Detection of a surface connected flaw with 4 MHz A27 DMA probes and an OmniScan MX2 flaw detector. |

Our DMA probes are available in custom frequency and element configurations or two standard models, the A17 and A27. The standard DMA models work with our NDT SetupBuilder software and OmniScan flaw detector. DMA wedge designs are optimized for volume and surface flaw detection and are compatible with probe-in-hand manual inspection or with the MapSCANNER™, ChainSCANNER™, or VersaMOUSE™ encoded scanners.

Dual matrix array probes extend the inspection range of the OmniScan MX2 and FOCUS PX™ instruments for coarse-grained austenitic stainless steel and Inconel alloy materials and welds.

Get In Touch

.jpg?rev=76A4)