Przegląd

This product has been discontinued

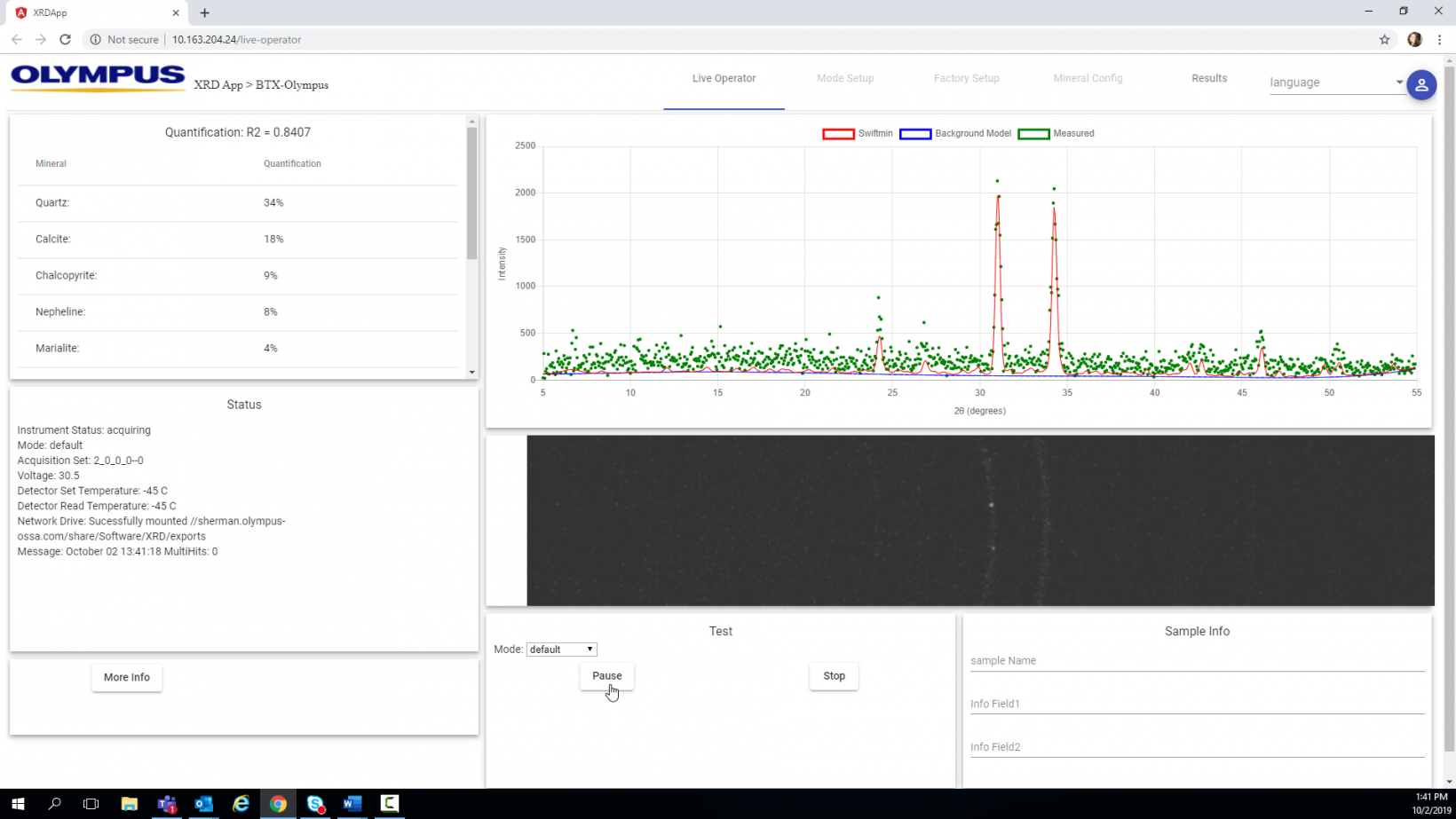

BTX™ III Benchtop XRD AnalyzerThe BTX III X-ray diffraction (XRD) analyzer provides fast, reliable quantitative mineralogy of major and minor components in a compact, benchtop design. The BTX III analyzer features a unique small sample holder to provide a lightweight and virtually maintenance-free alternative to conventional XRD. This standalone instrument runs without the need for compressed gas, water cooling, a secondary chiller, or external transformer, keeping the cost of ownership low. Operators can directly connect the XRD instrument to any device using Ethernet or wireless capability. Our XRD tools are powered by intuitive SwiftMin® software to streamline your workflow with a single dashboard, preset calibrations, easy data export, and automatic data transfer. |  |

|---|

| Increased Speed and Sensitivity Power Swift DecisionsPowerful, intuitive software is paired with improved X-ray detectors for enhanced sensitivity, faster analysis times, and more reliable results.

|

|---|

Sample Prep Made EasyUsing conventional X-ray diffraction instruments, a large batch of sample must be finely ground and pressed into a pellet to ensure a sufficiently random orientation of the crystals. In contrast, the small vibrating sample holder utilized in the BTX III convects all particles within the sample chamber, ensuring data is virtually free of orientation effects. As a result, the instrument requires a mere 15 mg of sample, easily obtained using the supplied sample kit. |  |

|---|