Badanie połączeń

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.

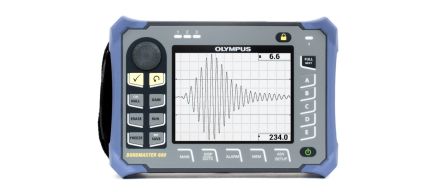

Our complete line of bond testing (BT) flaw detectors provides unmatched capabilities for the location of discontinuities and other flaws in composite structures. We offer a wide range of measurement features and application-specific options for flaw detection. Some of the primary applications include the location, identification and sizing of dis-bonds, delamination, and repair (putty) areas of honeycomb composite and composite laminates in aircraft structures(wings and flaps), high-performance racing vehicles, and boat hulls.

You are being redirected to our local site.