Wind Turbine Inspection Solutions

Save Time and Reduce Your Inspection Costs with Portable and Tailored Solutions

Blade Defect Types

- Impacts

- Wrinkles

- Delamination

- Lightning damage

- Disbonds

Inspection Technology

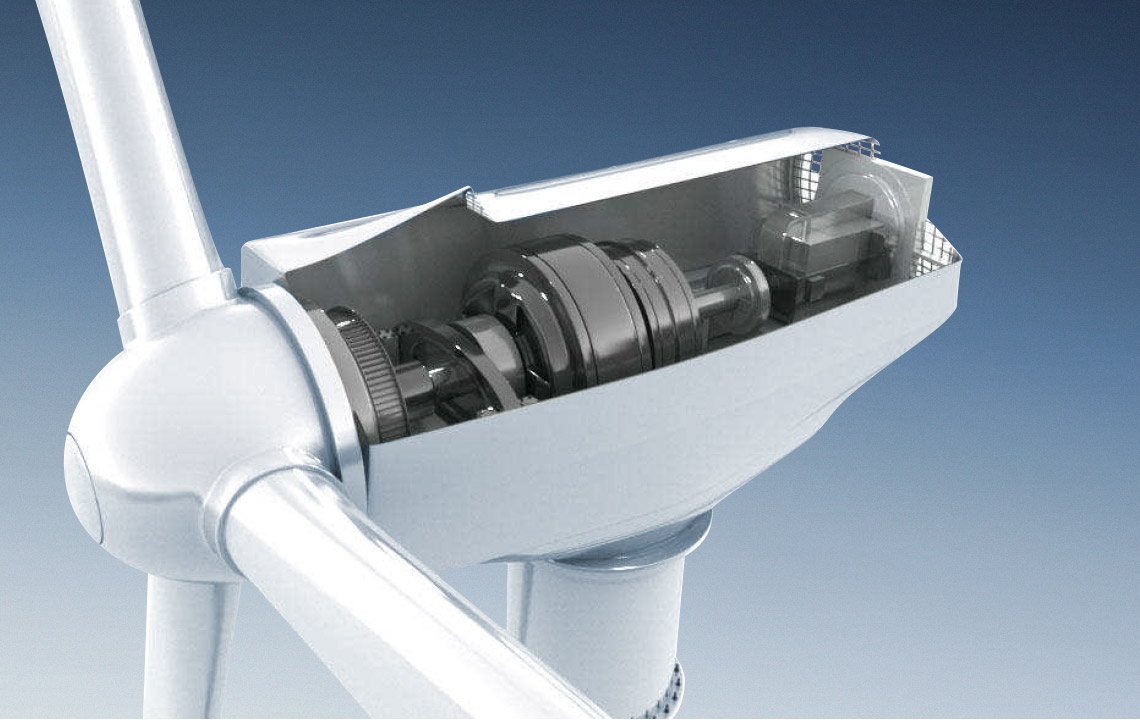

Gearbox Defect Types

- Cracks

- Color change

- Pitting

Inspection Technology

Tower Defect Types

- Cracks

- Lack of fusion

- Porosities

- Slags

- Corrosion

Inspection Technology

Gearboxes - Remote Visual Inspection

Gearboxes - Remote Visual Inspection

Inspect Gear Teeth and Bearings for Defects, Including Color Change and Pitting- Oil clearing scope adaptor saves time

- Increase the probability of detection with clear, sharp images

- Compact and lightweight, enabling use in difficult-to-access areas

Learn More

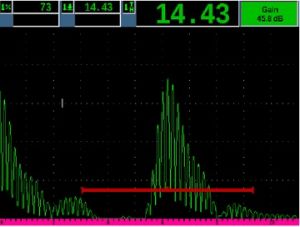

Gearboxes - Phased Array Ultrasound

Gearboxes - Phased Array Ultrasound

Locate Defects to Help Prevent Failures, Even When Access Is Limited- Phased array (PA) probes direct ultrasonic beams, facilitating the inspection of multiple areas

- Reduced inspection time compared to radiography

- Immediate, quantifiable results for on-site analysis

Learn More

Tower - Phased Array Ultrasound

Tower - Phased Array Ultrasound

Monitor the Health of Your Wind Tower- Quickly detect corrosion and cracks and archive your data

- Reduced inspection time compared to radiography

- Detect and fix process problems right away

Learn More

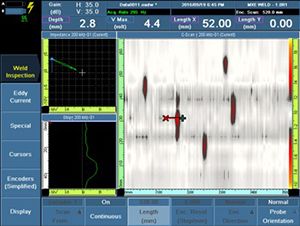

Tower - Eddy Current Array

Tower - Eddy Current Array

Quickly and Efficiently Inspect Welds on Towers- Detect cracks and weld defects without removing paint

- Replaces penetrant and magnetic particle testing

- Automatic lift-off compensation for accurate results

Learn More

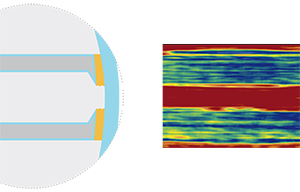

Blades - Phased Array Ultrasound

Blades - Phased Array Ultrasound

Inspect blade spar caps and shear web bonding- Efficiently inspect thick, attenuative materials, such as carbon fiber and glass fiber

- Wider coverage compared to conventional ultrasonic testing

- Configurable to scan in the longitudinal or transverse direction of the blade

Learn More

Blades - Conventional Ultrasound

Blades - Conventional Ultrasound

Evaluate Lightning Damage to Know when Repairs Are Required- Rugged, ergonomic instruments designed for challenging inspections

- Intuitive interface practical for both experienced and novice inspectors

- Full range of probes for detecting and sizing blade defects

Learn More

- Learn more about our EPOCH 6LT ultrasonic flaw detector

- Read our application note, "Laminar Cracking in Fiberglass"

- Learn more about our composite inspection solutions

- View our video, "EPOCH 6LT Flaw Detector for Rope Access Technicians"

- Read our blog post, "Creating a Highly Portable Flaw Detector from the Ground Up"

Blades - Bond Testing

Blades - Bond Testing

Inspect Blades for Disbonds and Delamination- Quickly and accurately detect disbonds and delamination in composites

- Automatic probe recognition with pre-programmed setup

- Lightweight and easy to carry

Learn More

Blades - Remote Visual Inspection

Blades - Remote Visual Inspection

Look Inside Blades for Damage and Quality Control- Scopes up to 30 m long for difficult-to-reach areas

- Portable and compact for field and in-line inspections

- Smooth, accurate approach to a target with precise articulation

Learn More

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.