Piston

Application

Pistons move inside an engine’s cylinders to generate the power needed to drive an automobile. For pistons to move smoothly, their side surfaces (piston skirts) need to be adequately lubricated.

Grooves on the pistons’ side surfaces help maintain a layer of lubricant. It is important that the oil grooves meet precise required specifications. Oil groove configuration must, therefore, be measured with high precision to help ensure the adequate sliding performance of components. Because pistons are cylindrical, specialized fixtures are needed to hold them on a microscope for observation of the side surfaces. These fixtures increase the overall height of objects on the observation stage of a microscope, which can potentially obstruct the movement of the objective lens above them.

Solution

The LEXT OLS5000 microscope uses lasers to perform 3D measurement of samples that are up to 210 mm high. This enables measurement of the sides of pistons that are mounted on fixtures.

LEXT OLS5000 product features

- This model is capable of observing and measuring samples up to 210 mm in height.

- Measurement performance is enhanced to four times the speed of the previous model.

- Improved resolution (plane resolution of 0.12 μm) enables high-precision measurement.

- Smart scan functionality enables the acquisition of high-precision data with a press of the start button, helping minimize differences in the data acquired by different microscope operators.

Images

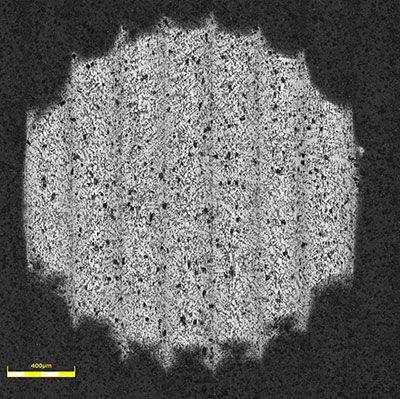

Piston external view

Oil groove image provided by a laser microscope

(objective lens: 20X; zoom: 1x)

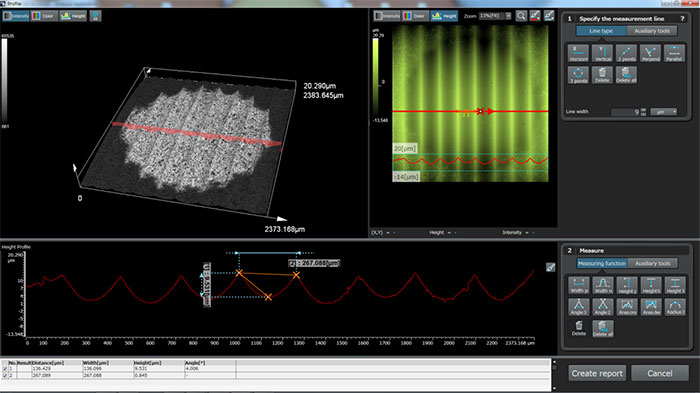

Piston mounted on a LEXT microscope

Shape measurement