Evident inspection microscopes provide flexibility by enabling users to view samples through various observation methods. This includes MIX observation, an illumination method that can mix darkfield with another observation method, such as brightfield, simple polarization, or fluorescence, to show more in your sample at once. MIX observation is also known as MIX illumination or MIX technology.

Figure 1. Schematic diagram of MIX observation.

Our U-MIXR-2 MIX slider, which is inserted into the revolving nosepiece of an inspection microscope, makes this observation method possible. Read on to learn more about MIX observation and how it aids wafer defect inspection.

Figure 2. U-MIXR-2 MIX slider shown from the front and back.

Figure 3. A compact microscope mounted onto a device with a U-KMAS illuminator equipped with the MIX slider.

Semiconductor Wafer Defect Inspection Using Brightfield and Darkfield

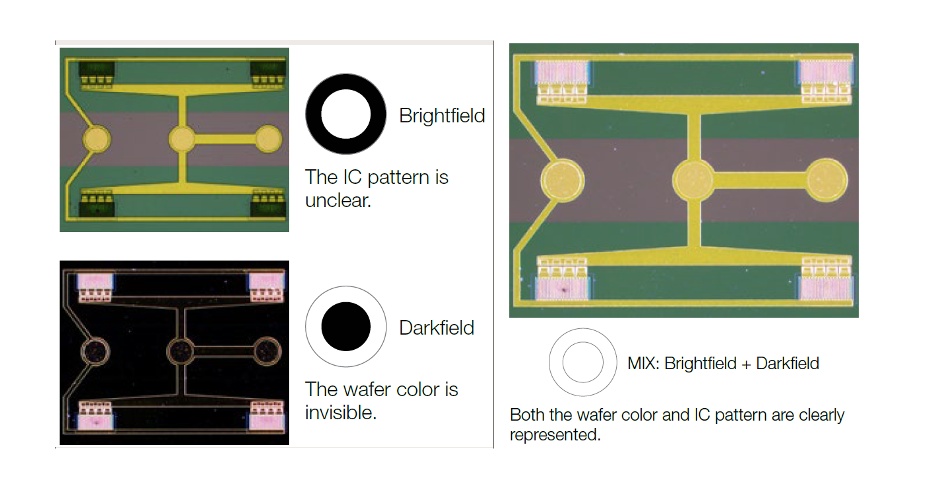

The combination of brightfield and darkfield through MIX observation is particularly useful for wafer defect inspection. Brightfield enhances surface detail such as color, while darkfield enhances edge details such as minute scratches and defects. By combining them into one method, users can see both the patterns and colors of a wafer at once.

Figure 4. Combining brightfield and darkfield observation shows the wafer’s color and integrated circuit (IC) pattern at once, enabling you to detect potential issues quickly and save time during inspection.

Identifying a Wafer’s Location Using Fluorescence and Darkfield

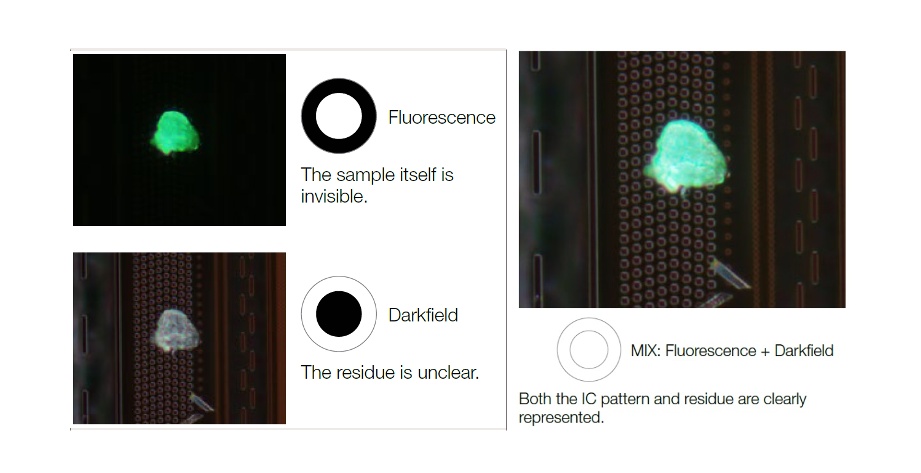

Another useful way to use MIX observation is by combining fluorescence and darkfield. In semiconductor inspections, fluorescence illumination is typically used to inspect for leftover particles of photoresist. However, it is often hard to determine the object’s position when using this illumination method. The good news is that the object position can be found using darkfield. In wafer inspection, combining fluorescence and darkfield through MIX observation makes it possible to determine the position of a wafer, observe its pattern shape, and see unwanted resist.

Figure 5. Combining fluorescence and darkfield observation improves the inspection of the IC pattern and residue.

Flexible Illumination Using Directional Darkfield

An important advantage of MIX illumination is the directional darkfield feature, which enables you to control the amount and direction of light on the sample. The 16 LEDs can be controlled separately to illuminate an object at an oblique angle from any direction. This capability enables you to distinguish raised surfaces from depressions, as well as highlight new features and defects. You can also combine directional darkfield with brightfield, polarization, transmitted light, or fluorescence to further enhance details.

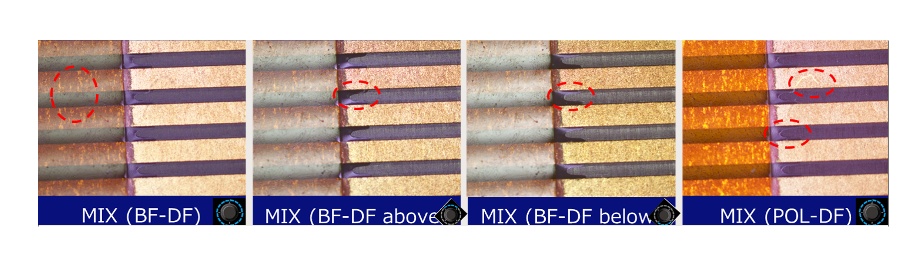

Check out the images below for directional darkfield examples:

Figure 6. Enhanced surface details in a ribbon cable by combining directional darkfield with another observation method using MIX observation. The blue on the dial shows the direction of the light from directional darkfield, while the red circle indicates the area under observation.

Figure 6 images from left to right:

- MIX observation using brightfield and darkfield lets you observe the polyimide cover surface and copper foil at the same time

- MIX observation of brightfield and darkfield angled above lets you observe the plane part and shape inclined below at the same time

- MIX observation of brightfield and darkfield angled below lets you observe the plane part and shape inclined above

- MIX observation of polarization and darkfield lets you observe the contamination and concave shape at the same time

Mixing MIX Observation into Instrument Design

MIX observation can save time during inspections by showing more in your sample at once, making it a useful tool for applications that use a combination of darkfield and other observation methods.

- BX53M upright metallurgical microscope

- GX53 inverted metallurgical microscope

- MX63 / MX63L wafer inspection microscope

- STM7 measuring microscope

- BXFM modular microscopes

In addition, some older versions of our BX™ series and MX™ series microscopes can be updated with MIX observation using additional components.

To learn more about our high-quality optical components that can be incorporated into your imaging device, visit our OEM resource center . You can also visit our industrial microscopes page to learn about the microscopes that utilize MIX illumination.

Related Content

Detecting Manufacturing Defects on Semiconductor Wafers Using a Digital Microscope

A Smart Way to Control Contamination for High-Throughput Metrology and Inspection