개요

두께 및 결함 검사 솔루션고급 부식 검사를 위한 펄스/수신(PR) 이중 배열최신 위상 배열(PA) 검사 기술의 고급 기능을 지원하는 펄스-수신(PR) REX1 Dual Linear Array™(DLA) 프로브는 빔 발사 기능을 최적화하는 복잡한 배선을 특징으로 합니다. 이 PR 모델 DLA 프로브를 사용하면 펄서/수신기 모듈 없이 위상 배열 수집 장비를 사용하는 경우에도 고급 PA 검사를 시행할 수 있습니다. 표준 PA 이미징 외에도 REX1 DLA PR 프로브를 사용하여 효율적인 고품질 전체집속기법(TFM) 및 위상 일관성 이미징(PCI) 스캔을 수행할 수 있습니다. |  |

이점 및 특징

*PCI는 OmniScan X3 64 결함 탐상기에서만 사용할 수 있습니다. |

일반적인 응용 분야

DLA REX1 PR 프로브는 빠르고 효율적인 수동, 자동 또는 반자동 검사를 수행할 수 있도록 하며 고품질 이미징을 제공하여 결함을 정확하게 측정할 수

있습니다. 부식 모니터링은 물론 피팅, 크리프 손상, 수소 유도 균열(HIC)에 대한 중요 결함 평가에 선호되는 도구입니다.

|

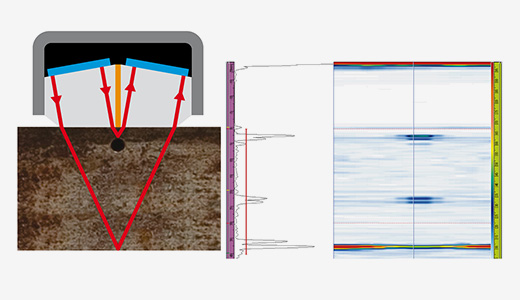

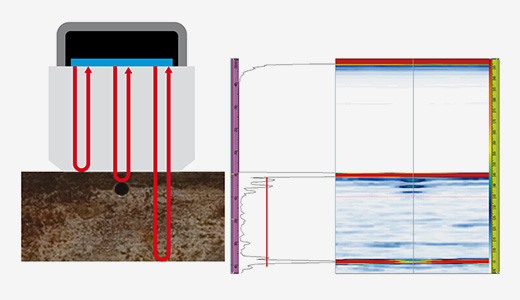

이중 배열 피치-캐치 기술이중 요소 UT 프로브와 마찬가지로 DLA 프로브에는 비스듬히 절단된 지연선에 장착된 별도의 송수신 요소가 통합되어 있습니다. 이 구성은 시험편 표면 아래에 초점을 맞추는 빔을 생성하여 표면 반사의 진폭을 상당히 감소시킵니다. 이로 인해 표면 근처 해상도가 향상되어 피팅, 크리프 손상 및 HIC(수소 유도 균열)와 같은 중요 결함에 대한 탐지 확률(POD)이 증가합니다. |

피치-캐치

| 펄스-에코

|

위상 배열 펄스-에코와 비교하여 피치-캐치 기술은 인터페이스 에코를 거의 생성하지 않아 더 나은 표면 근처 해상도를 제공합니다. | |

|

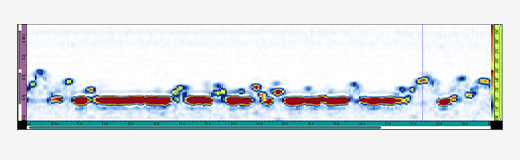

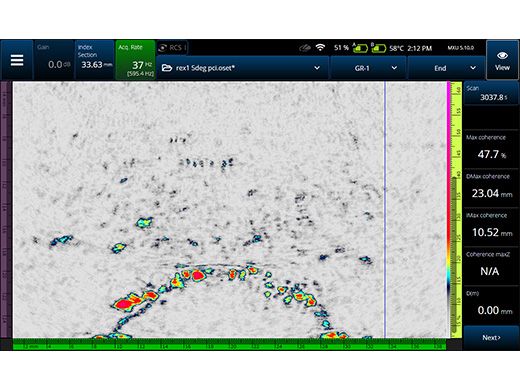

새로운 기능, 새로운 가능성전체집속기법(TFM) 및 위상 일관성 이미징(PCI)과 같은 최신 고급 초음파 기술에는 표준 이중 선형 프로브1의 발사 능력을 넘어서는 복잡한 발사 시퀀스가 포함됩니다. REX1 DLA PR 모델은 TFM이 있는 OmniScan™ X3 장치와 PCI 및 TFM이 있는 OmniScan X3 64 결함 탐상기의 복잡한 초점 법칙 요구 사항을 지원하도록 최적화되었습니다. 강철의 수소 유도 부식(HIC)에 대해 수집한 데이터의 이러한 예에서 볼 수 있듯이 REX1 DLA PR 프로브는 고품질 PA 이미징뿐만 아니라 효율적인 TFM 및 PCI 스캐닝을 가능하게 합니다. |

|

|

1 요청 시 DLA 프로브의 레거시 비-PR REX1 및 ULT1 버전을 계속 사용할 수 있습니다. 이러한 레거시 DLA 프로브는 홀수/짝수로 연결되며(1-2,3-4 등) 펄서/수신기 모듈이나 통합 펄서/수신기 기능이 없는 장비와 가장 잘 호환됩니다(예: OmniScan MX2). 이러한 프로브는 현재 OmniScan X3 스캔 계획의 프로브 라이브러리에서 사용할 수 있지만 비-PR 버전은 TFM 또는 PCI 등의 고급 스캔 계획에서 사용할 수 없습니다. 호환성을 극대화하기 위해 OmniScan X3 시리즈는 DLA 프로브 사양으로 사전 구성되어 있어 검사 설정을 빠르고 쉽게 할 수 있습니다. TFM 또는 PCI 스캔 계획을 생성할 때 프로브 목록에서 간편히 DLA 모델을 선택하고 장비에서 직접 초점 법칙 구성을 진행하면 됩니다. DLA 프로브, OmniScan X3 시리즈, TFM 및 PCI의 기능에 대해 자세히 알아보십시오. |

사양

프로브 사양 및 치수

| 7.5DL32-32X5-REX1-P-2.5-OM-IHC-PR-RW | 7.5DL32-32X5-REX1-P-5-OM-IHC-PR-RW | ||

|---|---|---|---|

| 품목 번호 | Q3301867 | Q3302172 | |

| 주파수(MHz) | 7.5 | 7.5 | |

| 요소 개수 | 이중 32 | 이중 32 | |

| 피치(mm) | 1 | 1 | |

| 활성 개구부(mm) | 32 | 32 | |

| 입면(mm) | 5 | 5 | |

| 케이블 길이(m) | 2.5 | 5 | |

| 외부 치수 mm(인치) | L | 66 (2.57) | 66 (2.57) |

| W | 40 (1.58) | 40 (1.58) | |

| H | 44 (1.73) | 44 (1.73) | |

자원

브로셔솔루션 |