QuickScan

Overview

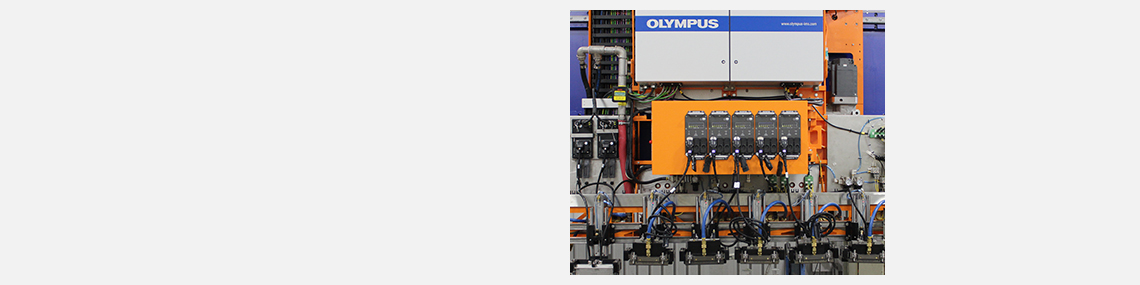

QuickScan LT PA

Phased Array Acquisition UnitThe QuickScan™ LT PA (16:256 or 32:256) instrument is our latest generation of phased array acquisition units for industrial inspection systems. The acquisition unit meets IP55 standards and easily integrates into industrial environments. The unit is managed by QuickView™ advanced software designed for ultrasonic and eddy current inspection. |  |

QuickScan UT

Multichannel Ultrasound SystemThis system offers many powerful features suited to high-speed ultrasound inspections, such as in-line testing, and is managed by QuickView advanced software designed for ultrasonic and eddy current inspection. |  |

QuickScan iX ECA

Eddy Current Array Acquisition UnitThe QuickScan iX ECA unit is designed to inspect ferrous and nonferrous materials using multicoil ECA probes. The capabilities and flexibility of this system make it suitable for many applications, such as surface inspections or measurement of material properties. This system is managed by QuickView advanced software designed for ultrasonic and eddy current inspection. |  |

Specifications

| Phased array channels | 256 |

|---|---|

| Number of pulsers |

16:256: 16 consecutive elements

32:256: 32 consecutive elements or 2 time 16 consecutive elements |

| Data acquisition rate | Up to 4 MB/s (A-scan rate) |

| Acquisition speed |

Up to 8000 8-bit A-scans/second of 512 points each

20 kHz for C-scan |

| Rectification | FW, HW+, HW–, and RF |

| Filtering | Digital band-pass, high-pass, and low-pass filters |

| Voltage |

PA : in 50 Ω 25 V, 50 V, 67 V

UT : 20 kHz for C-scan |

| Gain | 74 dB |

| Pulse width | 50 ns to 500 ns (steps of 2.5 ns) |

| Bandwidth (-3 dB) | 0.6 MHz to 22.5 MHz |

| Number of beams | Up to 512 |

| Pulse repetition frequency (PRF) | 1 Hz to 20 kHz |

| Real-time averaging | 1, 2, 4, 8, 16 |

| Number of gates | 3 detection gates + 1 for synchronization |

| Encoder | 2 axes (quadrature, clock direction, Up, Down) (1 to 65536 steps) |

| Network interface | 1000BASE-T |

| Size (W × H × D) |

29.5 cm × 13.3 cm × 45.8 cm

( 11.6 in. × 5.2 in. × 18 in.) |

| Weight | 4.2 kg (9.2 lb), 12.5 kg (5.7 lb) |

| IP rating | IP55 |

| Total peak power consumption | 63 W |

| DC input | 24 V |

| Acquisition depth | 81.9 µs |

| TCG | 0 to 74 dB, step 0.1 dB, 10 ms/step of 10 ns |

| Temperature range | Operating 0 °C–45 °C (32 °F–113 °F), Storage -20 °C–70 °C (-4 °F–158 °F) |

Applications

Tube Inspection Systems

Seamless and welded tube inspection systems use ultrasonic phased array and X-ray fluorescence spectroscopy technologies for comprehensive inspection.

Bar Inspection Systems

Bar inspection systems use advanced technologies, such as ultrasonic phased array, eddy current array, and X-ray fluorescence spectroscopy, to inspect the full volume and surface of round or square bars and pipes.