개요

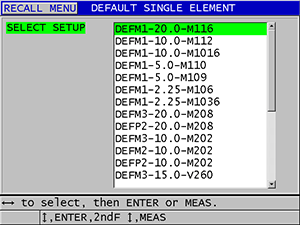

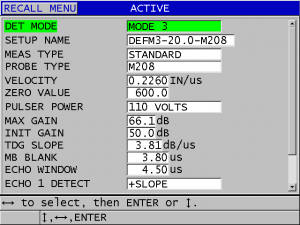

In addition to the velocity and zero calibrations discussed in the previous section, ultrasonic thickness gauges require a series of hardware and software settings that affect the shape and size of the outgoing sound pulse and how received echoes are processed and timed. These settings will change depending on transducer selection and the type of material and thickness range being measured. In some cases these parameters are set automatically by means of probe recognition software, especially in the case of corrosion gauges. In many other cases an operator can simply recall a pre-programmed gauge setup that includes the appropriate settings for a particular application. However advanced gauges also allow the user to adjust setup parameters and create optimized setups as required for applications not otherwise covered.

Custom setups are typically used when the measurement requirements of a particular application are not optimally met by one of the standard setups available in a gauge.

Setup adjustments of this type should be made only by a qualified technician who is familiar with the basic theory of ultrasonic gauging and the interpretation of ultrasonic waveforms. Many of these adjustments are interactive, and all of them have an effect on measurement range and/or measurement accuracy. In most cases, adjustments should not be attempted without monitoring waveforms via built-in waveform displays or auxiliary programs. Additionally, when establishing a custom setup for a specific application, it is essential to verify performance on reference standards representing the material(s) and thickness range to be measured before taking data.

The next section discusses some adjustable setup parameters that are commonly found in advanced ultrasonic gauges. Note that not all of these adjustments will necessarily be available in a given model.