Rotační systém pro kontrolu hutních polotovarů (RBIS)

Přehled

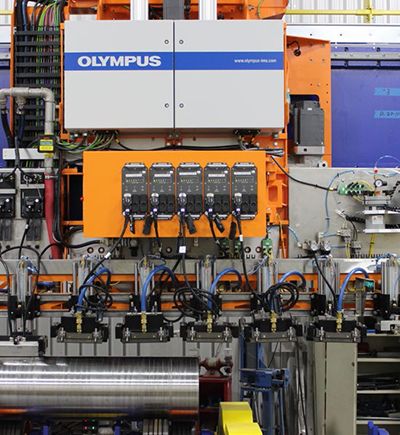

The rotating billet inspection system (RBIS) is a turnkey solution that uses phased array (PA) and eddy current array (ECA) technology integrated into a fully automated testing system to meet stringent requirements for volume and surface inspections. Key benefits include:

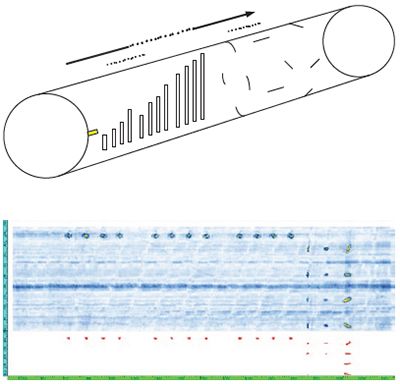

Complete Billet Inspection

Full Body Inspection with Phased Array

While the billet is rotated, the inspection head travels on a gantry along its length. Air cylinders move the wedges down at the beginning of the inspection sequence and up at the end.

The probes are mounted in Olympus water wedges that have many degrees of freedom and pneumatic suspension, helping ensure optimal coupling.

Specific wedges are used for longitudinal and shear waves to inspect both the billet’s volume and subsurface.

Surface Inspection with Eddy Current Array

Surface-breaking defects are inspected using eddy current array. A special probe holder is used to enable in-contact inspection with optimized lift-off for any billet diameter. The probes feature a ceramic face, making them resistant to damage.

High-Quality Results

The system meets the productivity requirements of the metal manufacturing industry while adhering to the highest international quality standards.

Water WedgeThe water wedge’s degrees of freedom and pneumatic suspension enable it to follow the pipe’s movement. The wedge uses an Aqualene membrane that maintains a thin film of water for excellent coupling. The water path inside the wedge remains undisturbed for high repeatability on small reference defects. Wear plates are available to fit the diameter of your billet. |  |

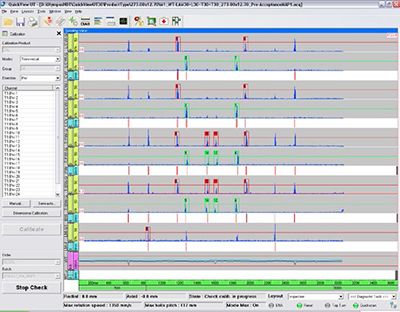

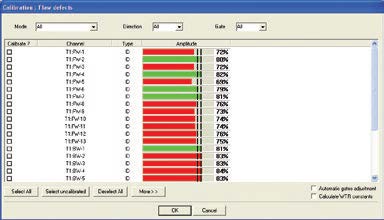

Automatic Calibration

To achieve a thorough inspection, each probe must be calibrated. During calibration, the apertures of each probe pass over a known defect, and the probe’s gain level is automatically adjusted. This feature enables users to easily perform and validate a precise calibration of each focal law, saving time without relying on the user’s skill.

|  |

Software and Acquisition Units

Phased array (PA) and eddy current array (ECA) technology, a powerful acquisition unit, and advanced software deliver a powerful inspection system.