![]()

Separators in Lithium-Ion Battery

Application

Li-ion battery cells contain separators, which are porous films made of polyethylene, polypropylene, etc. The separators provide a barrier between the cathode and anode that prevents short-circuiting in the battery. If material failure in a battery cell causes its temperature to rise above a predefined limit, the film dissolves, and the pores that normally allow Li-ion to pass through are closed. This stops battery charging and discharging, prevents a further rise in temperature, and eliminates the risk of an overheated battery or fire.

It is important to accurately evaluate the condition of separators to ensure uniform film thickness and similarly sized, evenly distributed pores. A good separator surface condition allows Li-ion to move smoothly, which enables the efficient flow of electric current.

Solution

The LEXT OLS4500 is a laser measuring microscope that combines laser microscopy with scanning probe microscopy (SPM) functionality to accurately observe and measure film thickness uniformity and the size of pores.

LEXT OLS4500 product features

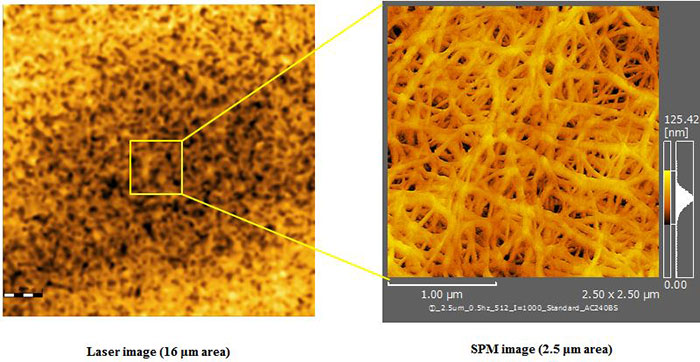

(1) Enables seamless observation and measurement using both a laser microscope and SPM on the same area of a sample.

(2) A laser microscope improves productivity when obtaining final SPM data.

Images

(Notes)

A bright-colored area in the laser microscopic image indicates that the area is high, while a dark-colored area indicates that it is low.

The laser microscopic image makes it easier to identify the area you want to observe with the SPM.