Micron-sized shape measurement using a laser microscope

Adhesive

1. Application

Mobile equipment such as smartphones and cell phones, compact cameras, car navigation displays, car stereos, and other electronic equipment are made up of numerous parts and need to function correctly in both high- and low-temperature environments. When electronic equipment expands or contracts due to changes in temperature, the adhesives used to bond components in the mobile equipment can loosen, negatively affecting the performance of the equipment. Therefore, it is important for the adhesives to be resistant to a wide range of temperatures. To evaluate the adhesive’s performance, manufacturers measure the volume of the adhesive drops at different temperatures.

2. The Olympus solution

Thanks to dedicated objective lenses with high numerical apertures and an optical system optimized to obtain maximum performance from the 405 nm semiconductor laser, Olympus' LEXT 3D scanning laser microscope can capture the profile of an adhesive drop without making contact with the viscous adhesive. Equipped with a photomultiplier that can capture weak reflections, the microscope can easily obtain the surface profile of a low-reflection transparent sample, which would be difficult to

capture with a conventional optical system. By performing volume measurement using the height data obtained via these features, the contraction and expansion of adhesives before and after thermal tests can be quantitatively measured, enabling the selection of a material less affected by thermal changes.

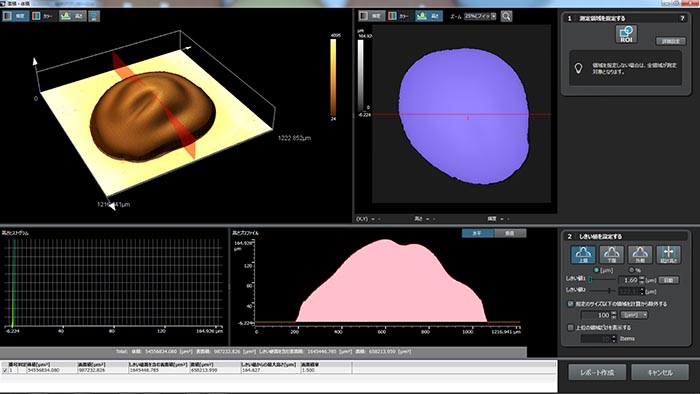

Images

3D and Volume measurement image