Application

Special purpose films are laminated together in an optical system to help liquid crystal displays (LCDs) maintain uniform brightness. Small displays use a light guide plate to help direct light through the panel. Light from a source, such as LEDs installed along the edge of a panel display, is scattered by the plate and repeatedly reflected to illuminate the front of the panel. The density of surface irregularities on the light guide plate is designed in such a way that the scatter is increased as the light travels away from the source. The light irradiated from the plate is made uniform by a diffuser plate. The light is then collected by the prism sheet, intensified, and directed through the TFT panel. Evaluating the surface profile, or roughness, of the light guide plate is important for ensuring uniform brightness in LCD displays.

Olympus' solution

By using Olympus' LEXT 3D scanning laser microscope, the light guide plate’s angle of taper and the peak-to-valley pitch or height can be measured with high resolution and high definition. Thanks to dedicated objective lenses with high numerical apertures and the advanced optical system designed for optimal performance with a 405 nm laser, the LEXT can capture the profile of irregular slopes that were previously impossible to detect, enabling you to acquire more reliable three-dimensional data and ensure the quality of light guide plates.

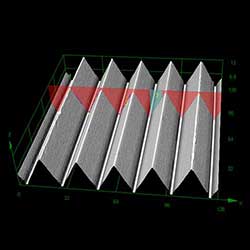

Three-dimensional surface profile of a light guide plate

100X objective lens; 1x zoom |