Увеличение яркости подсветки промышленных видеоэндоскопов

Introduction

An industrial videoscope is an instrument that enables inspectors to look inside areas that are otherwise difficult to access, such as the combustion chamber of a jet engine. Videoscopes support industry in a broad range of applications, including helping reduce time, labor, and cost by inspecting inside machined components and nondestructive maintenance inspections of components that would otherwise need to be disassembled. Videoscopes can be used to view objects of various sizes, ranging from components as small as a fuel injection valve or as large as a fuel tank or containment vessel.

Challenges

Olympus leverages the technology used in our medical videscopes to create videoscopes designed exclusively for use in industrial applications. The major differences between industrial videoscopes and medical videoscopes include:

- Medical videoscopes are used in and around organs while industrial videoscopes are primarily used on metal components and must be durable

- The length of the scope required for each type of inspection

- Size of the object being inspected

To address item one, the engineers replaced the resin-based material used on medical scopes with a metallic material that is durable, helping provide a long use life for the industrial scopes. For item 2, the longest medical scope is 2.7 meters, while the longest product in the lineup of industrial videoscopes is 30 meters. For item 3, being able to inspect large objects, as often required in industrial applications, requires a very bright light source to illuminate the area. Making sure that the light source has the intensity necessary for these inspections is very challenging. While organs and small components can be observed using conventional illumination, large spaces, such as tanks, require a much brighter light source.

Videoscopes are small instruments, and large lamps cannot be installed on them. For example, in a videoscope with an outer diameter of 6 mm, an observation lens and light source both need to be installed. In this instance, the width of the illumination source can, at most, be 1 mm. Moreover, ultra-wide lenses are sometimes used to view large objects, and the light must be properly diffused to achieve uniform brightness in the image.

The intensity of light, defined by the equation illuminance /lx = E, therefore illuminance is subject to the inverse-square law.

The concern of the effect the inverse square law has on lighting presumes a perfectly uniform dispersion of the light from a single point source of light. Bringing these concepts effectively into the real world are difficult and require much engineering.

With a conventional LED light source, the bright spot is large in proportion to the end face of the light guide, and it has been difficult to achieve efficient incidence and conduction of the light.

Solution

Olympus used its experience in designing optical systems and its precision manufacturing technology to create an ultra-bright illumination system for the IPLEX NX videoscope. This required us to overcome two challenges:

- Developing a very small but very bright light source

- Creating a glass mold lens that delivers even lighting

In developing a new light source, we were able to reduce the amount of space required while increasing the illumination by replacing the LED system in our conventional videoscopes with a powerful laser diode. In addition, to efficiently focus the light into a light guide with a diameter of approximately 1 mm, we installed a micro lens between the laser diode and light guide, increasing the efficiency of the light focus by more than three times.

To create even lighting, the diffusion light angle is set according to the angle of view of the lens. Previously, we used ball glass lenses on the back of the cover glass to produce diffused lighting with a large refractive index. However, this approach resulted in irregular reflection and refraction due to the shape of the ball glass lens and a large loss in the light emitting direction.

The IPLEX NX videoscope provides more efficient lighting by replacing the ball lenses with a glass mold lens fabricated with precision technology. This increased the emission efficiency to twice that of the conventional approach.

Magnified photo of a glass mold lens

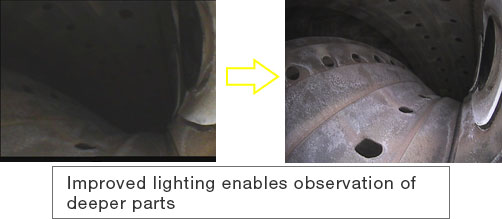

The result of these technological improvements is that we improved the light intensity of the IPLEX NX videoscope by a factor of five compared to a conventional videoscope. This ultra-bright illumination makes it easier to inspect large objects, such as storage tanks, since the images are sharp and bright. The increased brightness helps inspectors locate fine defects.

Conclusion

Olympus’s industrial videoscopes are the product of our optical manufacturing expertise. We will continue innovating new technologies to meet the changing needs of industrial inspections.