개요

This product has been discontinued

TERRA™ II Portable XRD AnalyzerThe successor to the world's first commercial battery-operated, portable XRD, the TERRA II analyzer has a battery life up to six hours and a rugged, weatherproof case for fast in-field analysis of major and minor mineral components. The TERRA II analyzer offers powerful features that make it a portable, lightweight, and virtually maintenance-free alternative to conventional XRD.

|  |

|---|

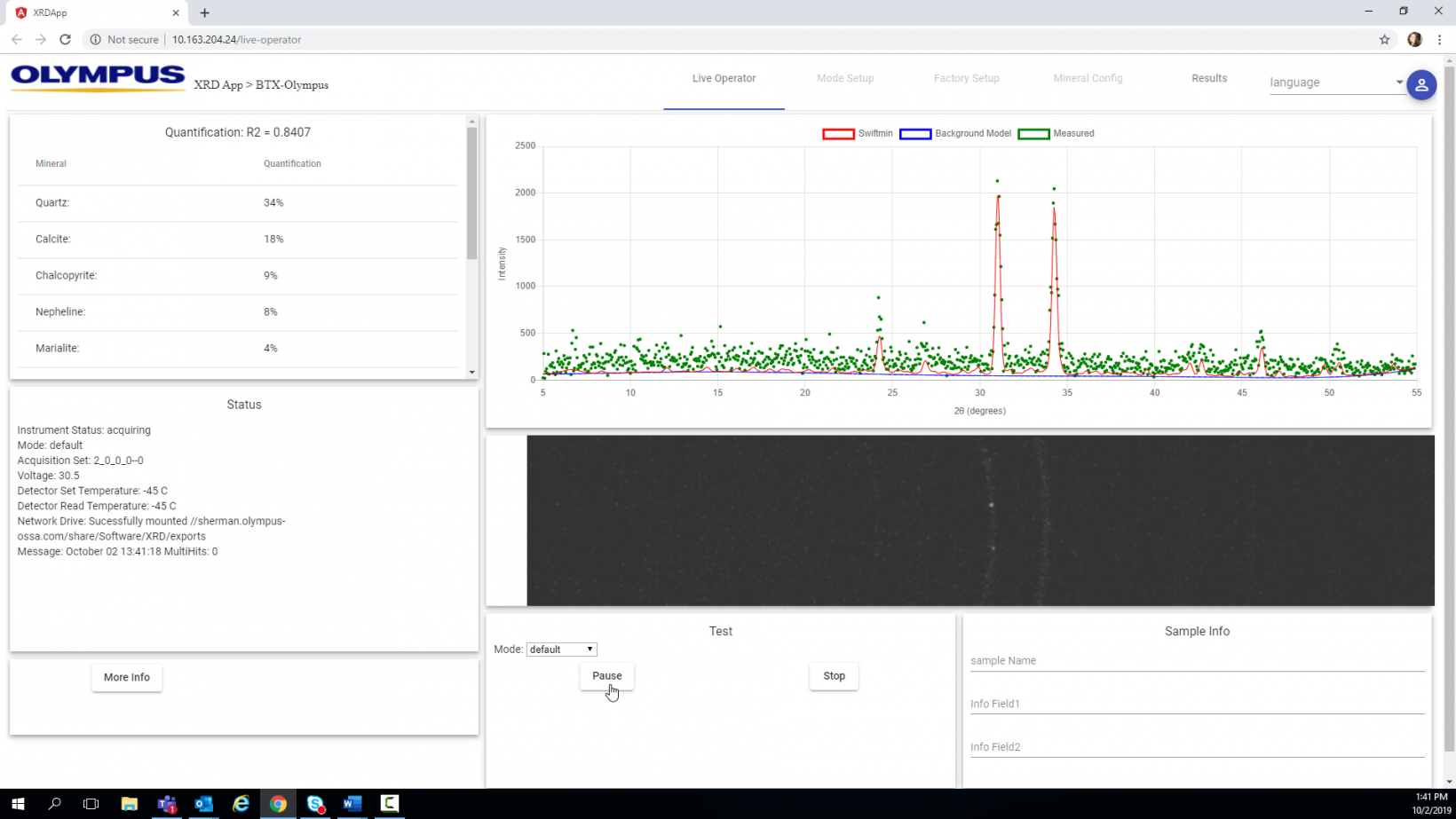

| Increased Speed and Sensitivity Power Swift DecisionsPowerful, intuitive software is paired with improved X-ray detectors for enhanced sensitivity, faster analysis times, and more reliable results.

|

|---|

Easy Sample PrepConventional XRD instruments require a large batch of sample to be finely ground and pressed into a pellet to ensure a sufficiently random orientation of the crystals. In contrast, the TERRA II analyzer’s small vibrating sample holder convects all particles within the sample chamber, ensuring that data is virtually free of orientation effects. As a result, only 15 mg of sample is required, easily obtained using the supplied sample kit. |  |

|---|