DELTA Alloys and Metals Handheld XRF Analyzer

Přehled

The DELTA Knows Metals and Alloys

DELTA Alloys & Metals Handheld XRF Analyzers provide highly specific material chemistry to rapidly and accurately identify alloy grades and pure metals. Get alloy chemistry and grade ID in seconds, from simple sorting to challenging grade separations, from incoming material inspection to end-product verification. Configured with a standard package of 25+ elements, the DELTA generates alloy chemistry and grade ID in seconds. From simple sorting to challenging grade separations, the DELTA provides highly specific material chemistry to rapidly and accurately identify pure metals and alloy grades including, but not limited to: |

|

When you need a reliable analysis tool to provide fast and accurate Positive Material Identification (PMI), turn to the DELTA. From turnings, shavings, rods, and wires to small parts and components, to more sizeable material or structures, the DELTA provides anywhere, anytime testing with faster and more accurate results

than ever before.

When you need a reliable analysis tool to provide fast and accurate Positive Material Identification (PMI), turn to the DELTA. From turnings, shavings, rods, and wires to small parts and components, to more sizeable material or structures, the DELTA provides anywhere, anytime testing with faster and more accurate results

than ever before.

Ultimate Aluminum Analysis

Easily and directly sorts and grades Aluminum and Aluminum containing materials. The DELTA Premium offers unmatched Al performance.

Aluminum Alloys

- Accurately measures Mg content in 5000 series alloys and separates Mg-containing alloys. Sorts 3003 and 3004; 1100 and 6063; 2014 and 2024

Titanium Alloys

- Accurately determines the Al content in Ti alloys, including CP Ti cut with Al

Red Metals

- Accurately classifies Al and Si bronzes

High-Temperature Cast Stainless

- Measures Al in high-temp, Ni/Co superalloys

|

|

DELTA Premium Alloy Analyzer with Weld Mask installed | Weld Mask AdaptorThe ruggedized weld mask can be attached to the front plate of the snout to collimate analysis to a 3 mm width slot, which is perfect for rapid, on-site weld bead analysis. The DELTA weld mask is engineering with layered metals to exclude substrate materials from analysis. |

Features

Exclusive DELTA Alloy Analysis Features

Exclusive DELTA Alloy Analysis Features

The DELTA is a reliable and rugged analyzer that maximizes both speed and accuracy. Other XRF systems have trade-offs. They may be able to identify alloys quickly, however inexperienced operators may not be able to determine whether an ID is incorrect, or whether longer testing is required. So how does the conscientious inspector maximize testing speed without increasing the risk of mistaken IDs or erroneous readings? Innov-X's SmartSort solution automates all these decisions, enabling even inexperienced operators to maximize both speed and inspection accuracy. This powerful feature yields optimized throughput and accuracy, making the DELTA an extremely productive XRF for alloy inspection.

DELTA for Positive Material Identification

With Newly Available X-act Count Technology

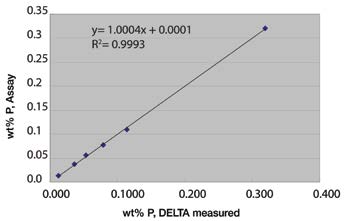

Superior Light Element Analysis

Traditionally a difficult area for handheld XRF, the analysis of light alloys and elements (Mg, Al, Si, P, S) can now be routine with the DELTA Alloy and Metal XRF Silicon Drift Detector (SDD) Analyzer with the newly available X-act Count Technology. Its integration with a 40kV Rhanode tube and automatic filtering provides fast, precise analysis of transition and heavy metals, and sensitive measurement of light element content. SmartSort maximizes testing throughput - sample by sample, testing

is automatically extended or terminated - maximizing accuracy and throughput.

DELTA SDD Analyzer Benefits

|  Correlation plot of Phosphorus (P) in Low Alloy Steel Analysis by DELTA Premium SDD Analyzer. |

SmartSort Mode

- Enables specific grades to be set up to automatically extend testing time, thus preventing mix-ups

- Maximizes effieciency for speed testing. Automatically extends tests for light elements (Mg, Al, Si, P, S) when absolutely necessary, thus eliminating unnecessarily long tests, and preventing mix-ups

- Makes the DELTA an extremely fast analyzer for inspections

Grade Match Messaging

- Enables qualitative information and messages to be added into the grade ID library

- Fully customizable messages allow for refinery-specific coding messages

- Can be used to store multiple messaging libraries for individual work sites

Welding Grade Library

High-Temperature ReadyThe DELTA is engineered to be utilized for in-service inspection of high temp systems with temperatures in excess of 426oC (800oF)

|

Analysis results display demonstrating nominal value (3% Al) and Tramp element (0.09% Fe) features. |

Tramp Library

- A long-time standard in OES systems, the DELTA is the first HHXRF to offer this feature

- Allows operators to set a max tolerated concentration for individual elements in 7 unique grade families; these elements are considered "Tramp"

- The DELTA comes preloaded with a tramp library based on industry standards

- The analyzer can identify and report tramp material, enabling the user to simplify grade matching by not having to count small, expected amounts of tramp elements against the grade match

- Detect and quantify tramp residuals critical to selective corrosion investigations and failure analysis

Easy Report Generation

|

Product Details

The DELTA

Everything You Need in Handheld XRF with State-of-the-Art Innovation

The New Generation DELTA Handheld XRF Analyzers are ergonomically advanced with a forward looking design incorporating the latest in electronics, components, and software technology.

The newly available DELTA X-act Count Technology can provide even better sensitivity and precision in faster time for more materials than before. Throughput is increased with the same or better precision in half the time for most elements.

The unique DELTA Docking Station frees you from having to power down the analyzer. The station charges the analyzer battery and a spare, and performs periodic calibration checks. DELTAs can be operated 24/7 in the field with hot swap battery replacement. |

| |||||||||||||||||||||||||||

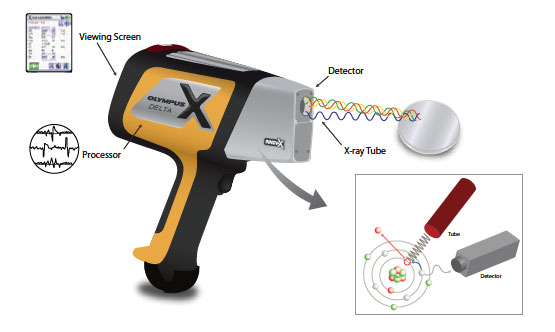

DELTA Handheld XRF Configuration

The DELTA brings the power and flexibility of handheld X-ray fluorescence spectrometry to the field. Ruggedized and ultra portable, this dramatically fast 24/7 technology provides accelerated testing times, allowing for hundreds more tests to be conducted per day with analytical confidence. The DELTA series analyzers are configured with powerful miniature X-ray tubes, Si-PIN detectors or highly advanced Silicon Drift Detectors (SDD), specialized filters, and multi beam optimization for the

ultimate in XRF field analysis. The DELTA's real overall value is to help make decisions in real time with minimal reliance on off-site laboratory testing.

Window Guard

| Window Guard™ System Protection for Testing Metal Turnings, Shavings & Protruding Components Using the DELTA Handheld XRF Alloy AnalyzerThe DELTA Handheld XRF Alloy Analyzer Window Guard System is ideal when testing conditions get really tough. It is designed to protect everything inside the DELTA's analyzing window from foreign objects. It safeguards the DELTA's detector, tube, filters, and electronics from damage by sharp objects, dirt, and debris. |

| DELTA Window Guard System is designed to save customers thousands of dollars in costly repair bills and down time.The economical DELTA Alloy Window Guard is easy to affix and remove where and when you need it. Simply remove the DELTA Alloy Window Guard to analyze elements lighter than Titanium (22) and make sure the correct calibration mode is selected. |