概述

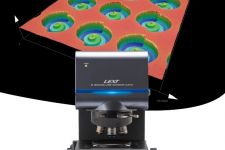

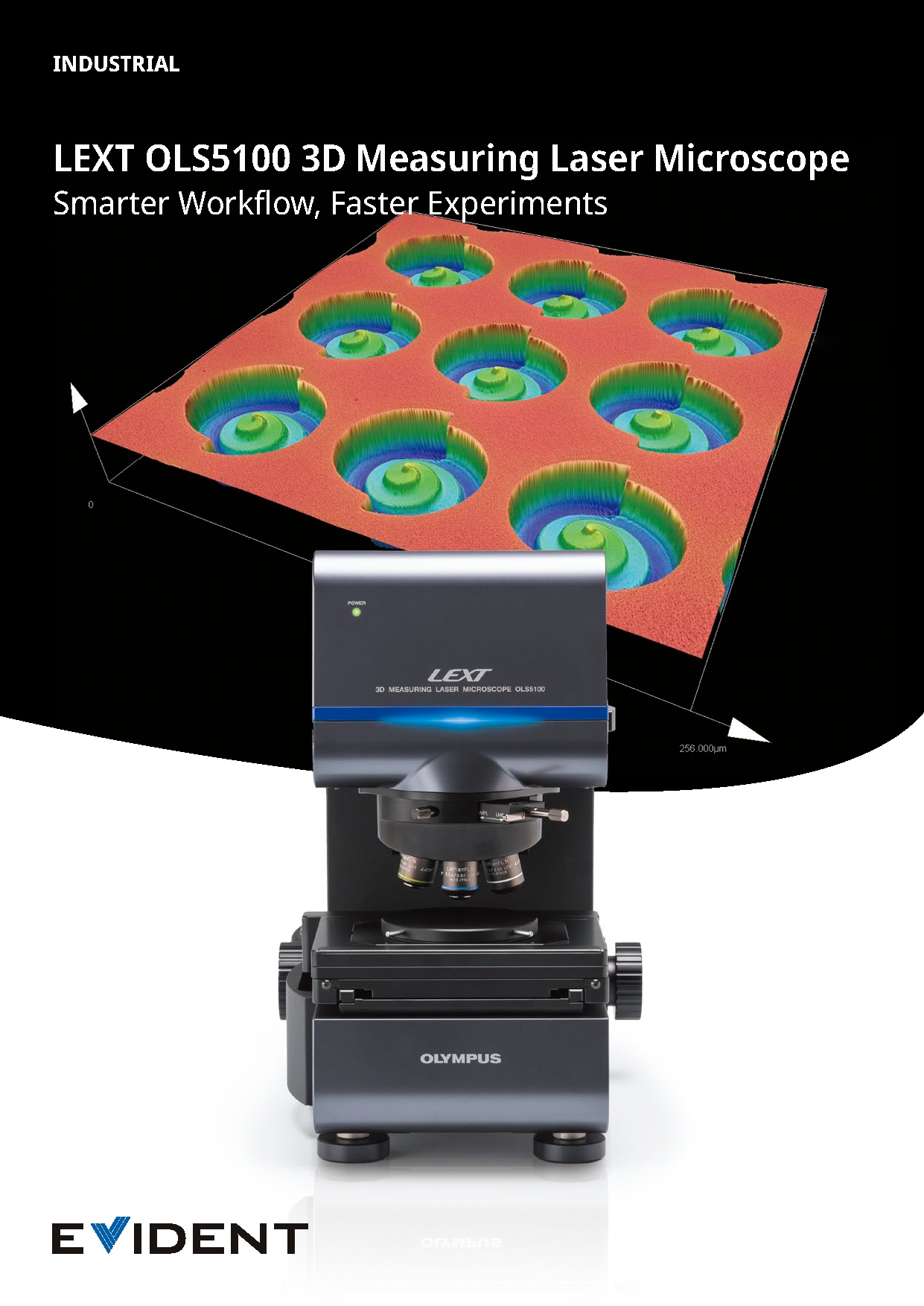

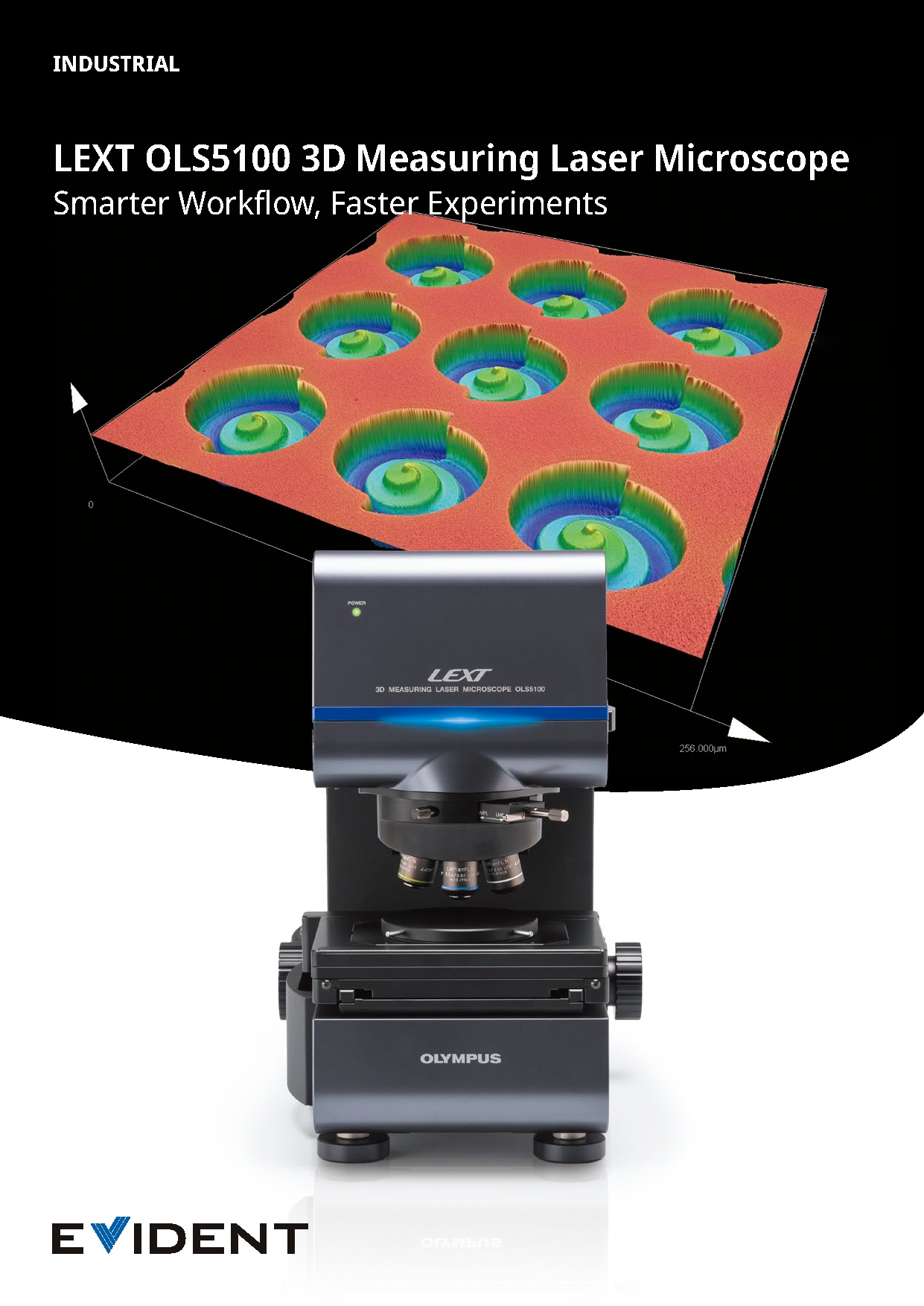

LEXT OLS5100 3D激光扫描显微镜用于材料分析的激光显微镜智能工作流程,更快地完成实验OLS5100激光显微镜专为失效分析和材料工程研究而设计,将出色的测量精度和光学性能与智能工具相结合,使显微镜使用起来更加方便。 它可以快速高效完成亚微米级形貌和表面粗糙度的精确测量,不仅简化了工作流程,还能提供值得信赖的数据。 观看视频 |  |

|---|

易于操作的激光扫描显微镜通过精心设计的软件,新手和有经验的用户都可以轻松使用显微镜。

本网页上的信息(包括保证的准确度)均基于Evident设定的条件。 |

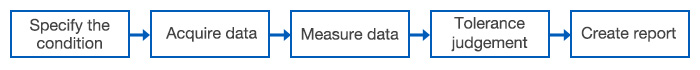

材料工程和失效分析实验更轻松智能实验管理器可将以前耗时的任务自动化,使亚微米级3D观察和失效分析实验工作流程变得更加简单。

|

可按照您的规格全面定制利用OLS5100激光扫描显微镜的所有高级功能,对大型和重型样品进行材料分析。 |  |

|---|

可以信赖的服务和支持从校准到培训,我们提供各种服务组合,帮助您的设备保持出色的性能。 Evident的服务合同:

|

|

优势特性

激光显微镜的优势特性 | ||

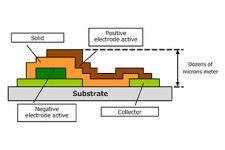

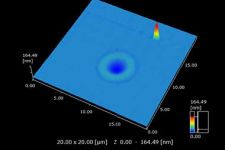

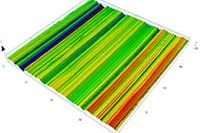

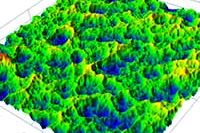

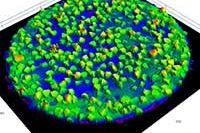

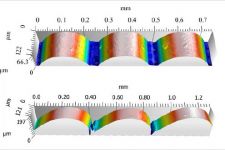

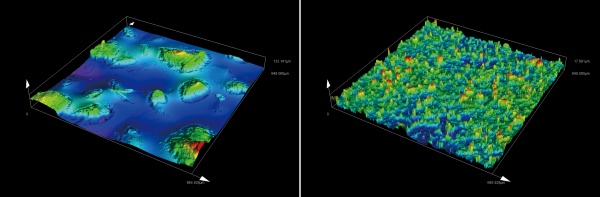

1. 亚微米级3D观察/测量  观察纳米范围内的台阶,测量亚微米级的高度差。 | ||

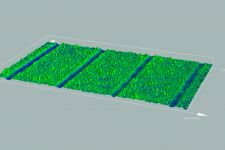

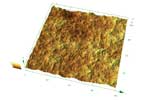

2. 符合ISO25178标准的表面粗糙度测量  可测量从线到面的表面粗糙度 | ||

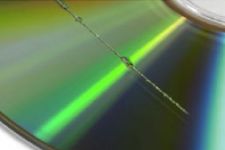

3. 无接触、无损、快捷  无需制备样品,只需将样品放在载物台上即可开始测量。 | ||

只需按一下按钮,即可获得可靠的数据智能扫描II 无论是经验丰富的用户还是新手,都能使用Smart Scan II(智能扫描II)功能快速轻松地获取数据。只需将样品放在载物台上,按下启动按钮即可,剩下的工作就由显微镜完成。

|  |

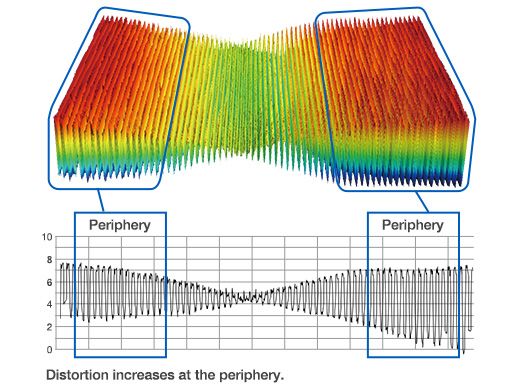

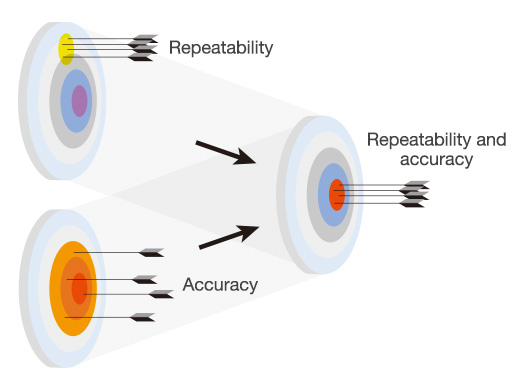

为您的运行环境量身定制测量性能保证 | |

| 准确度和可重复性均有保证 |

| 视场之外的表面测量 *仅适用于OLS5100-SAF/EAF |

用户友好型高分辨率/高倍率观察 | ||

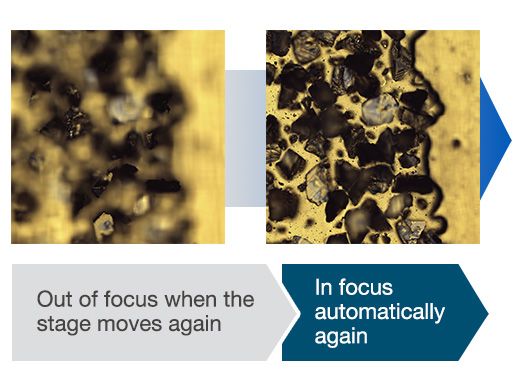

连续自动对焦 在移动载物台或更换物镜时,显微镜的连续自动对焦功能可保持图像的对焦状态,大幅减少了手动调整的需要。持续焦点跟踪功能可使您快速轻松地进行观察。 |  |  |

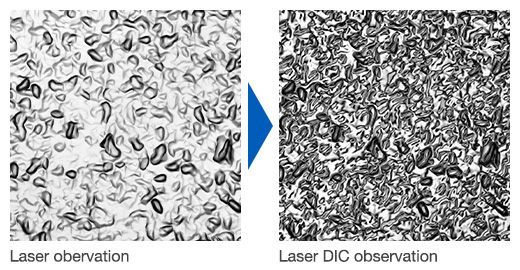

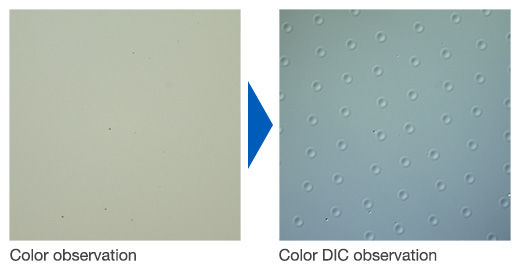

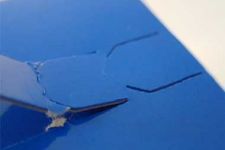

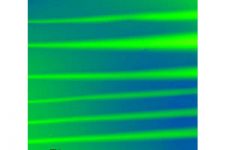

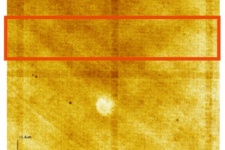

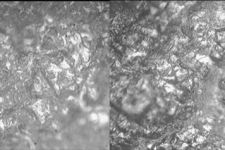

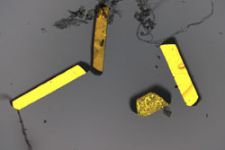

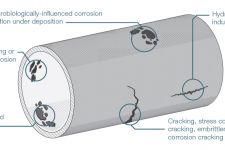

用于纳米级实时观察的双重微分干涉(DIC) 通过实时的纳米级观察,检测样品中的微小损伤。微分干涉(DIC)观察可使您观测到激光显微镜通常无法分辨的纳米级表面轮廓。借助DIC激光模式,就是使用5倍或10倍的低倍率物镜,OLS5100显微镜也可以获得与电子显微镜相当的实时图像。 |

晶片后表面 |

硬盘启停区 |

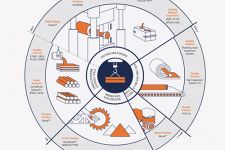

综合分析提供多种分析功能。以下仅为示例,详情请下载产品信息说明册或联系您当地的Evident代表。 | |

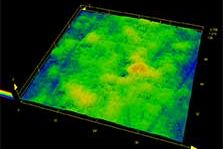

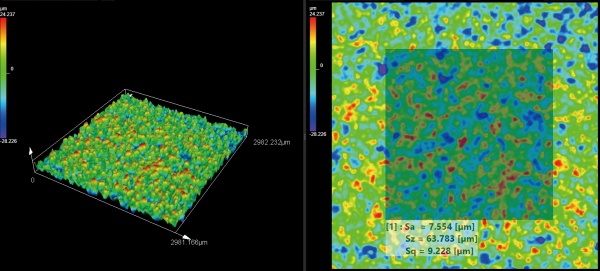

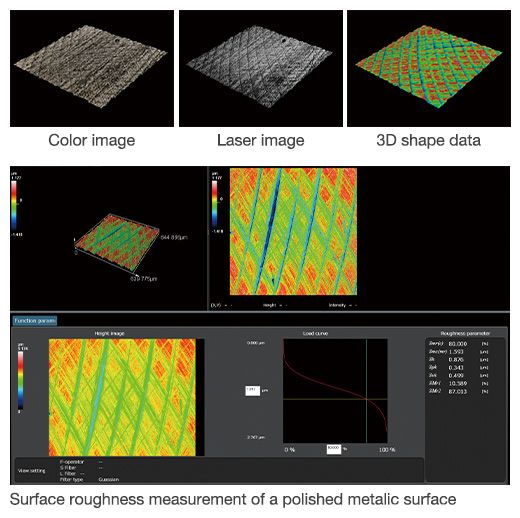

| 符合ISO25178标准的表面粗糙度测量 OLS5100显微镜使用0.4μm直径的激光束扫描样品表面,能够轻松测量接触式表面粗糙度仪无法测量的样品表面粗糙度。 同时还可以获取接触式表面粗糙度仪无法获得的表面彩色图像、激光图像和3D形貌数据,使得更多分析功能得以实现。 |

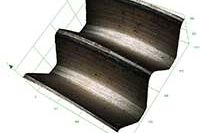

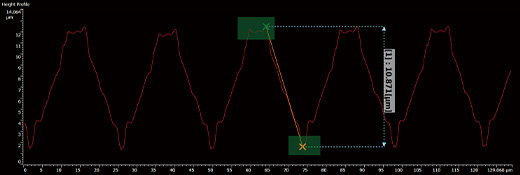

测量表面轮廓上最高点和最低点之间的台阶高差 | 轮廓测量/测量辅助工具 轮廓测量功能通过在图像中的待测位置上任意绘制测量线的方式显示表面轮廓。它还可以测量任意两个点之间的距离、宽度、横截面积和半径。与接触式测量工具不同,这种测量位置的设置非常简单。 可以在图像上标记测量线和测量点,因此即使是非常小的位点也能准确测量。有了测量辅助工具,就可以使用最高值点、最低值点、中间值点和/或平均值点准确指定待测点。在所获取的数据中指定了一个位点时,可根据指定条件自动提取特征点。 |

|

软件

简便的材料工程与失效分析实验管理 | |

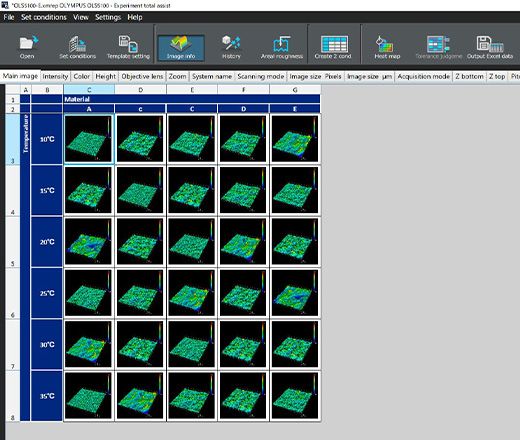

测试新材料时,实验条件的管理相当复杂,而OLS5100激光显微镜的智能实验管理器可以通过自动执行关键步骤(如创建实验计划)来简化流程。 |  |

自动化日常工作流程 | |

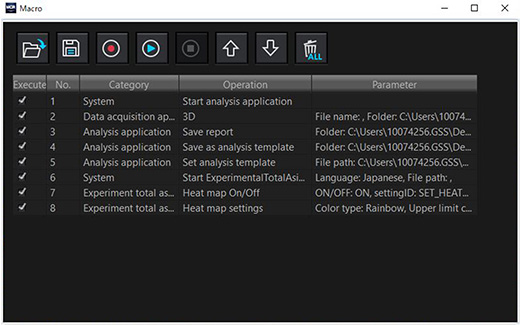

| 宏功能 您可以使用宏制作工具自动化整个检测工作流程。轻松创建和编辑程序,然后运行已注册的宏文件,即可获得可靠的结果。结合智能实验管理器,只需单击一下,即可做出通过/未通过的判断。 |

简化数据整理过程 | |

| 快速数据排序 |

| 自动数据输入 |

轻松整理实验条件数据 | |

自动生成文件名 您可以点击实验计划中的每个单元格,软件就会自动生成一个包含评估条件的文件名,以方便记录保存。每个文件都包含相关的图像和数据。 |  |

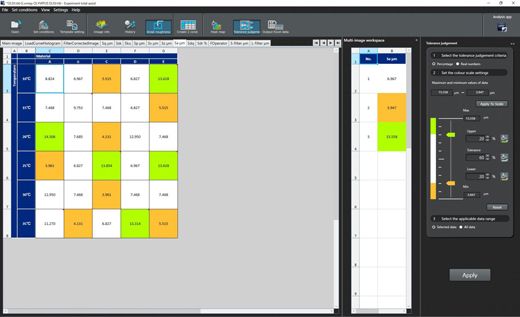

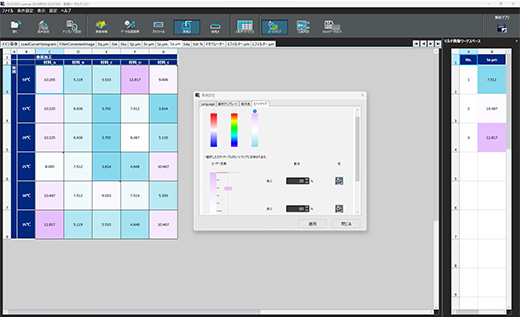

快速获得测量结果 | |

| 公差判断 |

| 热图 |

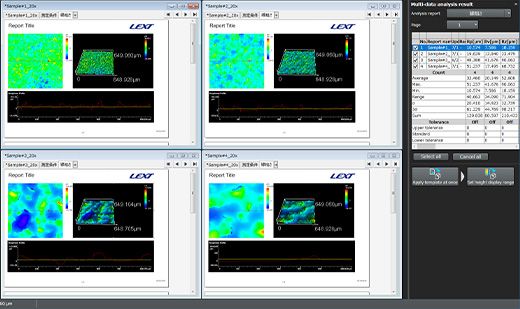

多数据分析 | |

| 数据对比分析 |

|

规格

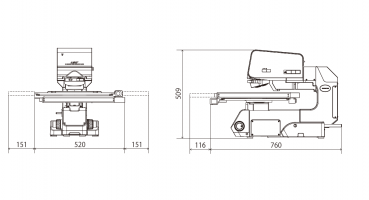

主机规格

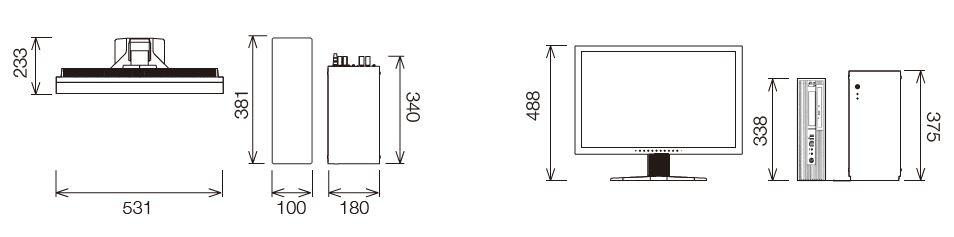

| 型号 | OLS5100-SAF | OLS5100-SMF | OLS5100-LAF | OLS5100-EAF | ||

|---|---|---|---|---|---|---|

| 综合倍率 | 54x ~ 17280x | |||||

| 视场 | 16 µm ~ 5,120 µm | |||||

| 测量原理 | 光学系统 |

反射型共聚焦激光扫描(激光)显微镜

反射型共聚焦激光扫描(激光-DIC)显微镜 彩色 彩色-DIC | ||||

| 测量原理 | 光接收元件 |

激光:光电倍增管(2通道)

彩色:CMOS彩色相机 | ||||

| 高度测量 | 显示分辨率 | 0.5 nm | ||||

| 高度测量 | 动态范围 | 16位 | ||||

| 高度测量 | 可重复性σn-1*1 *2 *5 | 5X:0.45μm,10X:0.1μm,20X:0.03μm,50X:0.012μm,100X:0.012μm | ||||

| 高度测量 | 准确度 *1 *3 *5 | 0.15 + L/100 μm(L:测量长度[μm]) | ||||

| 高度测量 | 拼接图像准确度 *1 *3 *5 | 10X:5.0+L/100 μm;20X或更高:1.0+L/100 μm(L:拼接长度[μm]) | ||||

| 高度测量 | 测量噪声(Sq噪声) *1 *4 *5 | 1 nm(典型值) | ||||

| 宽度测量 | 显示分辨率 | 1 nm | ||||

| 宽度测量 | 可重复性3σn-1 *1 *2 *5 | 5X:0.4μm,10X:0.2μm,20X:0.05μm,50X:0.04μm,100X:0.02μm | ||||

| 宽度测量 | 准确度 *1 *3 *5 | 测量值+/- 1.5% | ||||

| 宽度测量 | 拼接图像准确度 *1 *3 *5 | 10X:24+0.5L μm;20X:15+0.5L μm;50X:9+0.5L μm;100X: 7+0.5L μm(L:拼接长度[mm]) | ||||

| 单次测量时最大测量点数量 | 4096 × 4096像素 | |||||

| 最大测量点数量 | 3600万像素 | |||||

| XY载物台配置 | 长度测量模块 | • | 不适用 | 不适用 | • | |

| XY载物台配置 | 工作范围 | 100 × 100 mm电动 | 100 × 100 mm 手动 | 300 × 300 mm 电动 | 100 × 100 mm 电动 | |

| 最大样品高度 | 100 mm | 40 mm | 37 mm | 210 mm | ||

| 激光光源 | 波长 | 405 nm | ||||

| 激光光源 | 最大输出 | 0.95 mW | ||||

| 激光光源 | 激光分类 | 2类(IEC60825-1:2007,IEC60825-1:2014*6 | ||||

| 彩色光源 | 白光LED灯 | |||||

| 电气功率 | 240 W | 240 W | 278 W | 240 W | ||

| 质量 | 显微镜主体 | 约重31 kg | 约重32 kg | 约重50 kg | 约重43 kg | |

| 质量 | 控制盒 | 约重12 kg | ||||

*1 在ISO554(1976)、JIS Z-8703(1983)规定的恒温恒湿环境中使用时可达到规格要求(温度:20℃±1℃,湿度:50%±10%)。

*2 在使用MPLAPON LEXT系列物镜且放大倍率为20倍或更高时。

*3 在使用专用LEXT物镜测量时。

*4 在使用MPLAPON100XLEXT物镜测量时的典型值,可能与保证值不同。

*5 在Evident认证体系下有保证。

*6 OLS5100是2类激光产品。请勿盯着光束看。

** Evident提供的显微镜控制器已获得Window 10操作系统许可证。因此,Microsoft的许可条款适用,并且您要同意这些条款。请参阅以下Microsoft的许可条款。

https://www.microsoft.com/en-us/Useterms/Retail/Windows/10/UseTerms_Retail_Windows_10_english.htm

物镜

| 系列 | 型号 | 数值孔径(NA) | 工作距离(WD)(mm) |

|---|---|---|---|

| UIS2物镜 | MPLFLN2.5X | 0.08 | 10.7 |

| MPLFLN5X | 0.15 | 20 | |

专用LEXT物镜(10X) | MPLFLN10XLEXT | 0.3 | 10.4 |

专用LEXT物镜(高分辨率) | MPLAPON20XLEXT | 0.6 | 1 |

| MPLAPON50XLEXT | 0.95 | 0.35 | |

| MPLAPON100XLEXT | 0.95 | 0.35 | |

专用LEXT物镜(长工作距离型) | LMPLFLN20XLEXT | 0.45 | 6.5 |

| LMPLFLN50XLEXT | 0.6 | 5.2 | |

| LMPLFLN100XLEXT | 0.8 | 3.4 | |

| 超长工作距离物镜 | SLMPLN20X | 0.25 | 25 |

| SLMPLN50X | 0.35 | 18 | |

| SLMPLN100X | 0.6 | 7.6 | |

| 长工作距离LCD物镜 | LCPLFLN20XLCD | 0.45 | 8.3-7.4 |

| LCPLFLN50XLCD | 0.7 | 3.0-2.2 | |

| LCPLFLN100XLCD | 0.85 | 1.2-0.9 |

应用软件

| 标准软件 | OLS51-BSW | |||

|---|---|---|---|---|

| 标准软件 | 数据采集应用程序 | 分析应用程序(简单分析) | ||

| 电动载物台软件包应用程序*1 | OLS50-S-MSP | |||

| 高级分析应用程序*2 | OLS50-S-AA | |||

| 薄膜厚度测量应用程序 | OLS50-S-FT | |||

| 自动边缘测量应用程序 | OLS50-S-ED | |||

| 颗粒分析应用程序 | OLS50-S-PA | |||

| 实验流辅助应用程序 | OLS51-S-ETA | |||

| 球体/圆柱体表面角度分析应用程序 | OLS50-S-SA | |||

*1 包括自动拼接数据采集和多区域数据采集功能。

*2 包括轮廓分析、差值分析、台阶高度分析、表面分析、面积/体积分析、线粗糙度分析、面粗糙度分析和直方图分析。

Evident激光显微镜

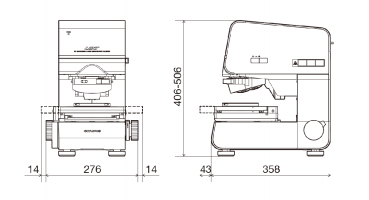

OLS5100-SAF配置示例

OLS5100-SAF

|

| |

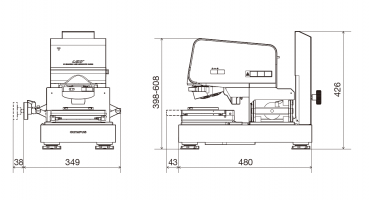

OLS5100-EAF

|

| |

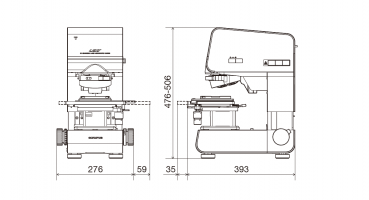

OLS5100-SMF

|

| |

OLS5100-LAF

|

|

控制单元