Устройство датчиков

To achieve optimal inspection performance, there are several important parameters to consider when designing an effective eddy current probe. Key factors include inspection coverage, sensitivity, frequency and, of course, cost. To optimize performance, it is important to carefully balance the various probe parameters. For example, high-sensitivity probes require small, high-frequency coils (providing less coverage); probes capable of greater coverage require larger, lower-frequency coils (resulting in decreased sensitivity to small defects). As is the case with conventional eddy current inspections, choosing the correct probe characteristics is essential to a successful inspection.

Where:

n = Number of channels

r = Resolution (also depends on the coil configuration)

C = Coverage

Probe Structure

Eddy current array probes can be optimized for a specific application by changing the probe shape and the coil configuration. Most coil configurations can be expanded into an array configuration.

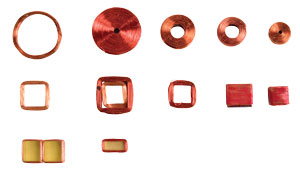

Single coil probe

The earliest instruments used in aircraft inspection included the Magnaflux ED-500 and ED520, and the Foerster Defectometer (although not a bridge type instrument but a resonant circuit type), all of which used single-coil probes. The probes contain a single coil that is wound to a specific value. No other coil is needed. More recently, the introduction of the Hocking Locator and newer models of the Foerster Defectometer have kept this kind of instrument as a popular option for many users. When these probes are used with a bridge circuit type instrument, a balance coil is also required. Balance coils are normally placed in the cable connector or a separate adapter (see Fig. 1).

Fig. 1

It sometimes creates a problem when the probe inductance value is not close enough to the value of the balance coil, and the instrument does not balance correctly. This happens more often when they are not made by the same manufacturer. The result is poor performance (noisy or insensitive) or no response at all (signal saturation).

Bridge Type probes

In this configuration the probe coils are located in an electrical "bridge" (see fig. 2). The instrument balances the bridge and any change in balance is displayed as a signal.

Fig. 2

In this arrangement, the same coil produces the eddy currents and detects the impedance changes caused by the defects (or any other variables). Almost all instruments are able to operate with this type of coil arrangement.

Reflection type probe

These probes are also known as send-receive or driver-pickup. In this configuration, the eddy currents are produced by a coil connected to the instrument's oscillator (driver).

Fig. 3

The signals received back in the probe are detected by separate coils called pickups (see Fig. 3 and Fig. 4). All new impedance plane instruments and also many older models are able to operate in both bridge and reflection modes. If you are in doubt, call the manufacturer or give us a call.

Fig. 4

Bridge or reflection

This is a common question asked by those involved in trying to select the best probe for an inspection. The answer is "It depends." Let us consider both systems.

Gain. Reflection probes will give a higher gain, particularly if they are "tuned" to a specific frequency, but normally the difference is on average about 6 dB. It is true that t his doubles the signal, but if you consider that the instruments are able to give this increase of gain easily, it is not so important. Nevertheless, in critical applications this increase is very welcomed.

Frequency range. Reflection probes do not need to balance the driver to the pickup coils. This means that they will give a wider frequency range. As long as the driver produces eddy currents, the pickup will detect them and some signal will be displayed. This may not provide good information at certain frequencies, but the probe is still working!

Bridge type probes used to give a limited frequency span in the older instruments, as these had to balance an electrical bridge using its other arms (X and R controls). In modern instruments, the bridge is normally formed with fixed precision resistors, or a fixed transformer inside it. The signals detected in this manner are electronically processed without any "mechanical" adjustments, and this means a greater ability to balance over a wider frequency range.

Drift: Probe drift is mostly caused by temperature change in the coils. This may be caused by varying ambient temperature, or the heat produced by the oscillator current, or both. There are design parameters that can be optimized to reduce drift, such as wire diameter and ferrite selection, but reflection probes are normally a good choice to avoid this problem even more.

In a reflection probe, the driver current does not flow through the pickup coils; in fact, the magnetic field received back from the specimen is normally much smaller and, consequently, the current flowing in the pickups is also reduced. Most probe types (pencil, spot, ring, bolt hole, etc.) can be made as bridge or reflection. Keep in mind that a reflection probe is almost invariably more difficult to manufacture and therefore more expensive.

Absolute and differential probe

This is an area where some confusion exists. Many users have called a probe "differential" when the signal displayed gives an up and down movement or a figure 8 type signal. This is caused by the two coils sensing the defect in sequence. When both sensing coils are on the probe surface, they compensate for lift-off and as a result no line is visible (see Fig. 5).

Fig. 5

In contrast, an absolute display is produced by a single sensing coil (see Fig. 1 through Fig. 4), giving a single, upward movement with a near horizontal lift-off line.

Others have called a probe "differential" simply when the coils were connected differentially such as in a bridge circuit. The problem with this definition is that probes can be connected differentially in a reflection system as well as when using two pickups (such as most scanner-driven bolt hole probes). In this case, the two pickup coils are positioned close to one another and contained within a driver coil (see Fig. 6).

The best way out of this confusion is often to specify the probe as bridge-differential, absolute, or reflection-differential-absolute as needed. It seems to make more sense to qualify the description according to the displayed signal, since this is what really matters. Not many people are concerned as to how the coils are connected internally.

Shielded and unshielded probes

Probes are normally available in both shielded and unshielded versions; however, there is an increasing demand for the shielded variety. Shielding restricts the magnetic field produced by the coils to the physical size of the probe or even less. A shield can be made of various materials, but the ones mostly used are: ferrite (like a ceramic made of iron oxides), Mumetal®, and mild steel.

Ferrites make the best shields because they provide an easy path for the magnetic field but have poor conductivity. This means that there are few eddy current losses in the shield itself. Mild steel has more losses but is widely used for spot probes and ring probes due to its machinability and when ferrites are not available in certain sizes or shapes. Mumetal® is used sometimes for pencil probes as it is available in thin sheet; however, it is less effective than ferrite.

Shielding has several advantages: first, it allows the probe to move in (or close to) geometry changes, such as edges, without giving false indications; next, it allows the probe to touch ferrous fastener heads with minimal interference; last, it allows the detection of smaller defects due to the stronger magnetic field concentrated in a smaller area.

On the other hand, unshielded probes allow somewhat deeper penetration due to the larger magnetic field. They are also slightly more tolerant to lift-off. Unshielded probes are recommended for the inspection of ferrous materials (steel) for surface cracks, and in particular with meter instruments. The reason for this is that the meter response is too slow to allow the signal from a shielded probe to be displayed at normal scanning speeds due to the smaller sensitive area.

Adapters

To connect a probe with a connector different from the type used in the instrument, it is necessary to use an adapter. An adapter consists of two different connectors joined and wired to match the inputs and outputs as necessary. It is normally housed in a short body that can be positioned at the instrument's input. Sometimes, it is also possible to have a "cable adapter," which is made to match a connector located at the probe body. Depending on the instrument's wiring, it may be possible to have a single adapter for both bridge and reflection. In other cases, it is necessary to have two separate adapters or use a switchable type.