Esta nota de aplicação explica como obter a espessura da parede e a concentricidade de tubos de metal e plástico de diâmetro pequeno. Conheça os equipamentos de medição ultrassônicos e os procedimentos usados para fazer medições de tubos de diâmetro pequeno.

Medindo a espessura da parede de tubos pequenos de metal e plástico

Tubos pequenos de metal e plástico com diâmetro menor que 3 mm ou 0,125 pol. são usados em uma ampla variedade de aplicações industriais e médicas. Como as paredes dos tubos são muito finas, as tolerâncias de fabricação para espessura e concentricidade são normalmente muito baixas. A espessura correta da parede é importante principalmente para produtos de segurança crítica, bem como para tubos usados em ambientes médicos. A medição ultrassônica oferece uma alternativa rápida e não destrutiva ao processo comum de corte de amostras de tubos para medição óptica de espessuras.

Equipamentos usados para medições de tubos de diâmetro pequeno

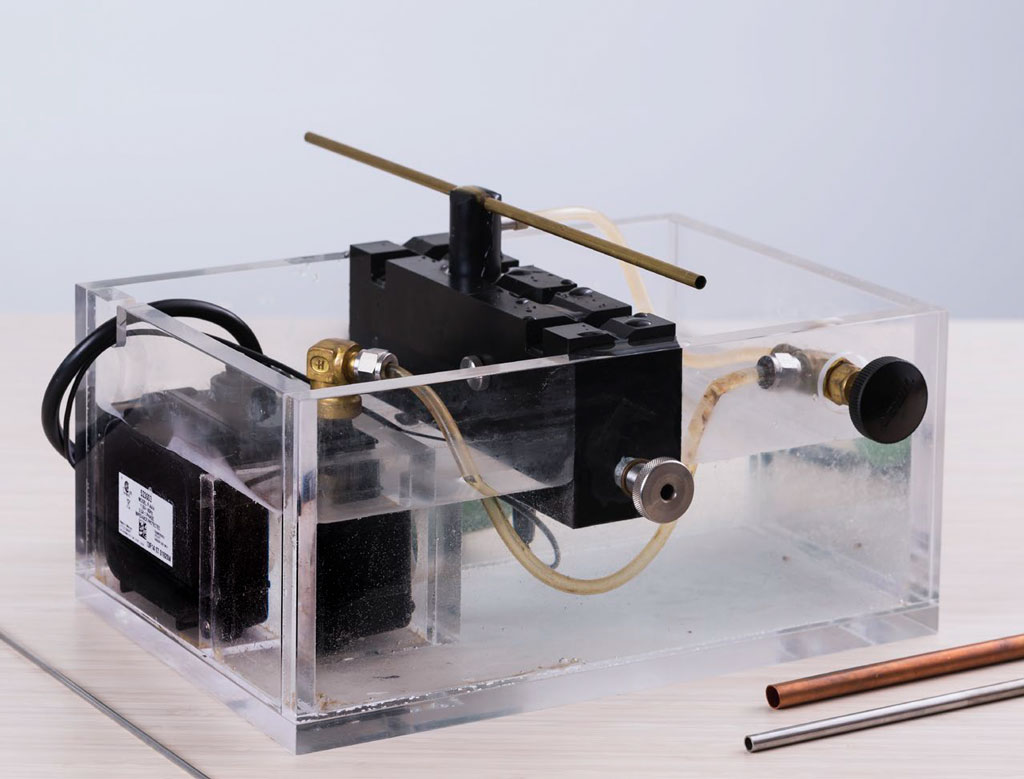

O instrumento recomendado para medições de tubos de pequeno diâmetro é o medidor de espessura ultrassônico 72DL PLUS™ ou 38DL PLUS™. O medidor 72DL PLUS oferece sondas de precisão e frequência mais altas para espessuras de parede mais finas, como tubos de diâmetro simples ou multicamadas com espessura da parede de até 0,001 pol. (25 μm). Para acoplar eficientemente a energia sonora em peças de teste de diâmetro pequeno, os inspetores devem focar o feixe de som em um ponto muito pequeno. Quando os diâmetros são inferiores a aproximadamente 3 mm (0,125 pol.), esse processo geralmente é feito com um transdutor de imersão focado de 20 MHz que foca o feixe de som através de uma coluna de água. O transdutor é comumente mantido em um borbulhador de sulco em V que posiciona a amostra do tubo no centro do feixe. O sistema borbulhador de recirculação RBS-1 é um tanque conveniente, bomba e acessório de montagem em borbulhador para medições de imersão em bancada.

Procedimento de medição ultrassônica para tubos pequenos de metal e plástico

A configuração ideal do transdutor e do instrumento para um determinado produto de tubulação é selecionada após o teste inicial das amostras do produto.

Usando um transdutor como um M316-SU (20 MHz, F = 0,75 pol.) e um dispositivo de fixação apropriado, como um borbulhador, o medidor 38DL PLUS é configurado para uma medição de Modo 3 (metal) ou Modo 2 (plástico). Essa configuração envolve o ajuste dos parâmetros de ganho e de branco para uma detecção de eco ideal. A espessura da parede mínima mensurável é tipicamente 0,1 mm (0,004 pol.) para diâmetros tão pequenos quanto 1,5 mm (0,060 pol.).

Para medições de espessura mais finas, use o medidor 72DL PLUS. Se um borbulhador de sulco em V for usado, a tubulação pode ser girada para obter rapidamente medições de espessura em toda a circunferência como uma verificação de concentricidade e deslizada para medir a espessura em diferentes pontos ao longo do comprimento. Como esse processo não é destrutivo, não há necessidade de cortar longas seções da tubulação para realizar a medição.

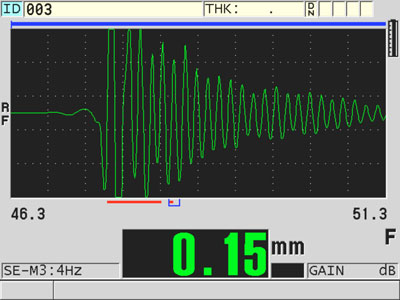

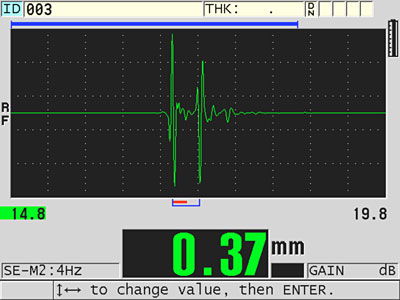

Os exemplos abaixo mostram medições típicas de tubos pequenos de metal e plástico com um medidor 38DL PLUS.

Tubulação de aço, 1,5 mm (0,060 pol.) de diâmetro, 0,15 m (0,006 pol.) de espessura da parede

Tubulação de plástico: 2 mm (0,080 pol.) de diâmetro, 0,37 m (0,014 pol.) de espessura da parede