Dieses Anwendungsbeispiel erklärt, wie die Wanddicke und Rundlaufgenauigkeit von Metall- und Kunststoffröhren mit kleinem Durchmesser ermittelt wird. Erfahren Sie mehr über Ultraschall-Dickenmesser und -verfahren, die zum Messen von Röhren mit kleinem Durchmesser verwendet werden.

Messung der Wanddicke von kleinen Metall- und Kunststoffröhren

Kleine Metall- und Kunststoffröhren mit einem Durchmesser unter 3 mm (0,125 Zoll) werden in vielen industriellen und medizinischen Anwendungen eingesetzt. Da die Röhrenwände so dünn sind, sind die Fertigungstoleranzen für die Dicke und Rundlaufgenauigkeit häufig sehr streng bemessen. Die richtige Wanddicke ist besonders wichtig für sicherheitskritische Produkte und Röhren im medizinischen Umfeld. Die Ultraschalldickenmessung bietet eine schnelle und zerstörungsfreie Alternative zum herkömmlichen Zerschneidungsprozess von Rohrproben für die optische Dickenmessung.

Ausrüstung für die Messung von Röhren mit kleinem Durchmesser

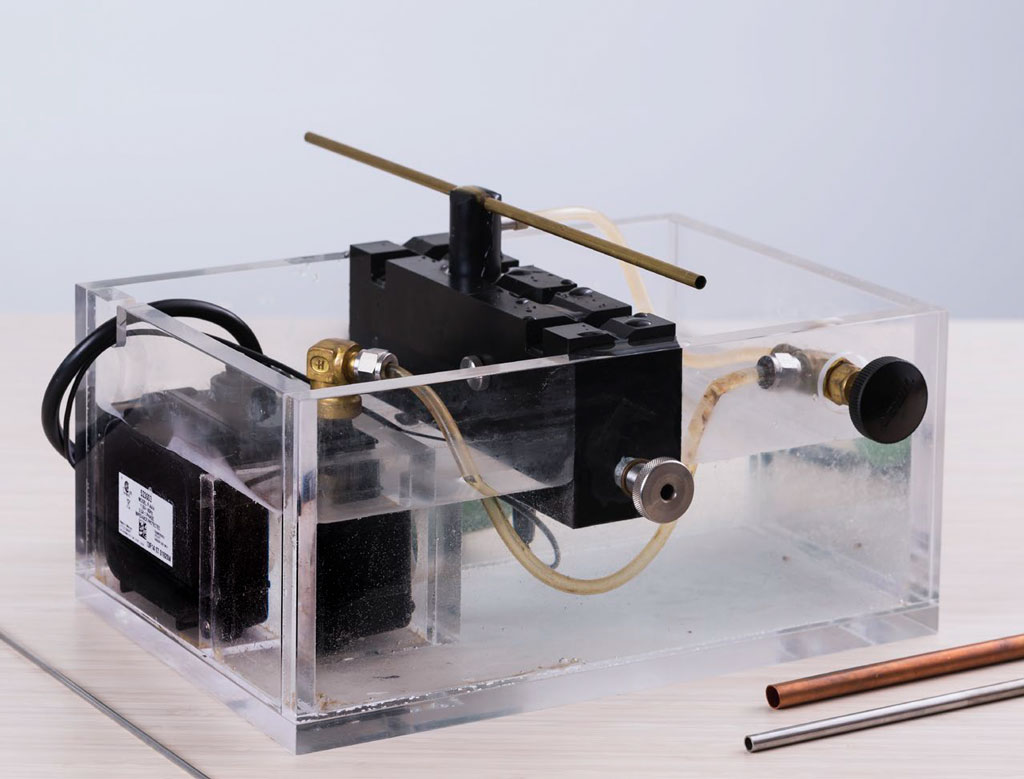

Das empfohlene Gerät für die Messung von Röhren mit kleinem Durchmesser ist der 72DL PLUS oder der 38DL PLUS Ultraschall-Dickenmesser. Der 72DL PLUS Dickenmesser kann mit Messköpfen mit höherer Präzision und höherer Frequenz für dünnere Wanddicken bis 0,001 Zoll (25 μm) eingesetzt werden. Um Schallenergie effizient an Prüfteile mit kleinem Durchmesser anzukoppeln, müssen Prüfer das Schallbündel auf einen sehr kleinen Punkt fokussieren. Bei Durchmessern unter ca. 3 mm (0,125 Zoll) wird dieser Vorgang normalerweise mit einem fokussierten 20-MHz-Tauchtechnikmesskopf durchgeführt, der das Schallbündel durch eine Wassersäule fokussiert. Der Messkopf wird üblicherweise in einen Wassersprudler mit V-Verankerung gehalten, der die Röhrenprobe mittig des Schallbündels ausrichtet. Das RBS-1 Wassersprudler-Umlaufsystem ist eine praktische Tauchbecken-, Pumpen- und Sprudler-Montagevorrichtung für Tauchtechnikmessungen auf einem Tisch.

Ultraschall-Dickenmessverfahren für kleine Metall- und Kunststoffröhren

Die optimale Messkopf- und Gerätekonfiguration für eine bestimmte Röhre wird nach anfänglichen Tests mit Proben ausgewählt.

Unter Verwendung eines Messkopfs, wie z. B. eines M316-SU (20 MHz, F = 0,75 Zoll), und einer geeigneten Befestigungsvorrichtung, wie z. B. eines Wassersprudlers, wird der 38DL PLUS Dickenmesser für eine Messung in Modus 3 (Metall) oder Modus 2 (Kunststoff) eingerichtet. Diese Einrichtung umfasst die Einstellung von Verstärkungs- und Unterdrückungsparametern für eine optimale Echoerkennung. Die minimale messbare Wanddicke beträgt typischerweise 0,1 mm (0,004 Zoll) bei einem Durchmesser von nur 1,5 mm (0,060 Zoll).

Für Dickenmessungen von dünneren Wanddicken eignet sich der Dickenmesser 72DL PLUS. Wenn ein Wassersprudler mit V-Verankerung verwendet wird, kann die Röhre rotiert werden, um schnell Dickenmessungen entlang des Umfangs bei Rundlaufgenauigkeitsprüfungen zu erhalten. Anschließend kann gewechselt werden, um die Dicke an verschiedenen Punkten in Längsrichtung zu messen. Da dieses Verfahren zerstörungsfrei ist, müssen für die Messung keine Röhrenabschnitte aufgeschnitten werden.

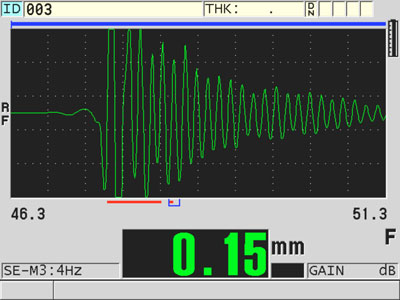

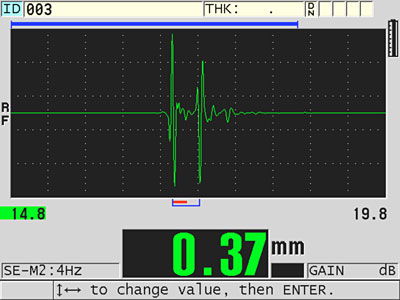

Die folgenden Beispiele zeigen typische Messungen von kleinen Metall- und Kunststoffröhren mit einem 38DL PLUS Dickenmesser.

Stahlröhre: 1,5 mm (0,060 Zoll) Durchmesser, 0,15 mm (0,006 Zoll) Wanddicke

Kunststoffröhre: 2 mm (0,080 Zoll) Durchmesser, 0,37 mm (0,014 Zoll) Wanddicke