This application note explains how to obtain the wall thickness and concentricity of small-diameter metal and plastic tubing. Learn about the ultrasonic gauging equipment and procedures used to take small-diameter tubing measurements.

Measuring Wall Thickness for Small Metal and Plastic Tubing

Small metal and plastic tubing with a diameter less than 3 mm or 0.125 in. is used in a wide variety of industrial and medical applications. Because the tube walls are so thin, manufacturing tolerances for thickness and concentricity are typically very tight. The correct wall thickness is especially important for safety-critical products, as well as tubing used in medical environments. Ultrasonic gauging offers a fast and nondestructive alternative to the common process of cutting tubing samples for optical measurement of thickness.

Equipment Used for Small-Diameter Tubing Measurements

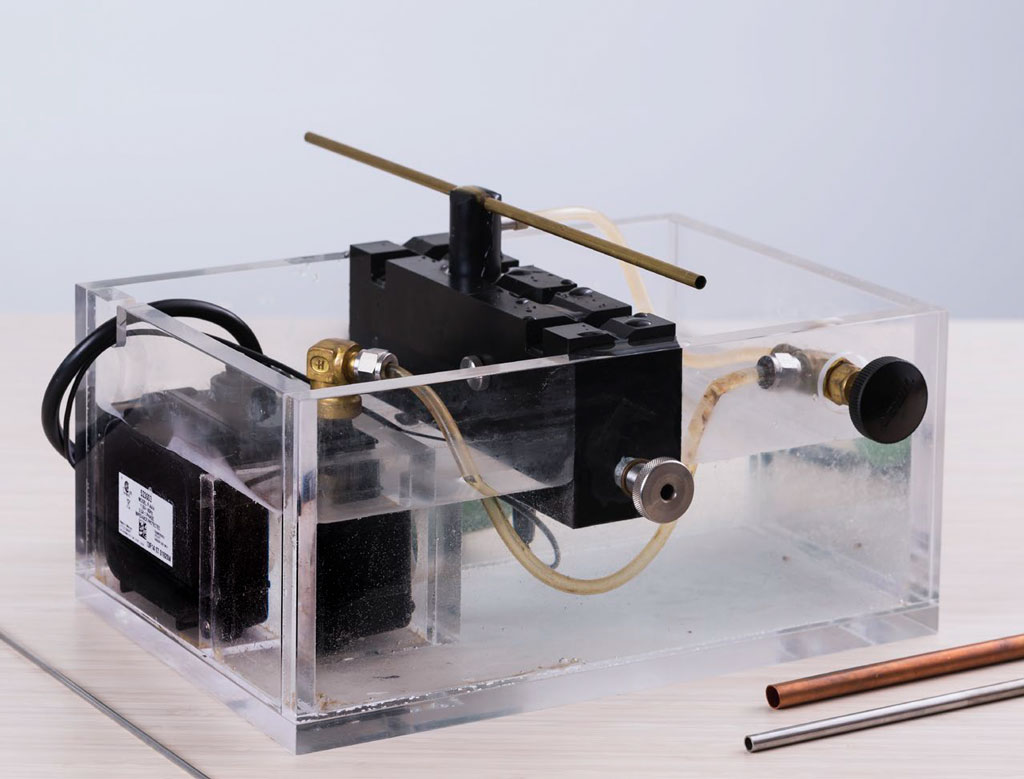

The recommended instrument for small-diameter tubing measurements is the 72DL PLUS™ or 38DL PLUS™ ultrasonic thickness gauge. The 72DL PLUS gauge offers higher precision and higher frequency probes for thinner wall thickness, such as single or multilayer diameter tubing with wall thickness down to 0.001 in. (25 μm). To efficiently couple sound energy into small-diameter test pieces, inspectors must focus the sound beam into a very small spot. When diameters are under approximately 3 mm (0.125 in.), this process is usually done with a 20 MHz focused immersion transducer that focuses the sound beam through a column of water. The transducer is commonly held in a V-notch bubbler that positions the tube sample in the center of the beam. The RBS-1 recirculating bubbler system is a convenient tank, pump, and bubbler mounting fixture for benchtop immersion measurements.

Ultrasonic Gauging Procedure for Small Metal and Plastic Tubing

The optimum transducer and instrument setup for a given tubing product are selected after initial testing of product samples.

Using a transducer such as a M316-SU (20 MHz, F=.75 in.) and an appropriate fixturing device such as a bubbler, the 38DL PLUS gauge is set up for a Mode 3 (metal) or Mode 2 (plastic) measurement. This setup involves adjustment of gain and blanking parameters for optimum echo detection. The minimum measurable wall thickness is typically 0.1 mm (0.004 in.) for diameters as small as 1.5 mm (0.060 in.).

For thinner thickness measurements, use the 72DL PLUS gauge. If a V-notch bubbler is used, the tubing can be rotated to quickly obtain thickness measurements all around the circumference as a concentricity check and slid to measure thickness at different points along the length. Since this process is nondestructive, there is no need to cut long sections of tubing for measurement.

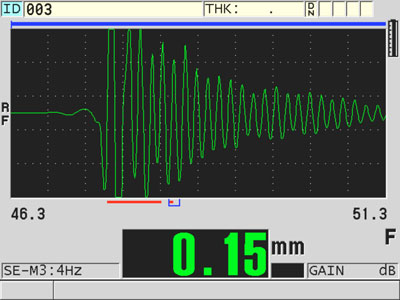

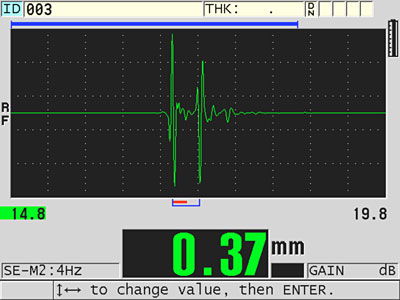

The examples below show typical measurements of small metal and plastic tubing with a 38DL PLUS gauge.

Steel tubing: 1.5 mm (0.060 in.) diameter, 0.15 mm (0.006 in.) wall thickness

Plastic tubing: 2 mm (0.080 in.) diameter, 0.37 mm (0.014 in.) wall thickness